Phosphogypsum-based mixed mortar wall spraying process

A technology of mixing mortar and phosphogypsum, which is used in construction, building structure, covering/lining, etc., can solve the problems of difficult control of the spraying quality of the outer surface of the wall, irregular spraying construction operation process, uneven surface of the coating layer, etc. Achieving the effect of saving time and labor, reducing fire hazards and smoothing the surface of calendering treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

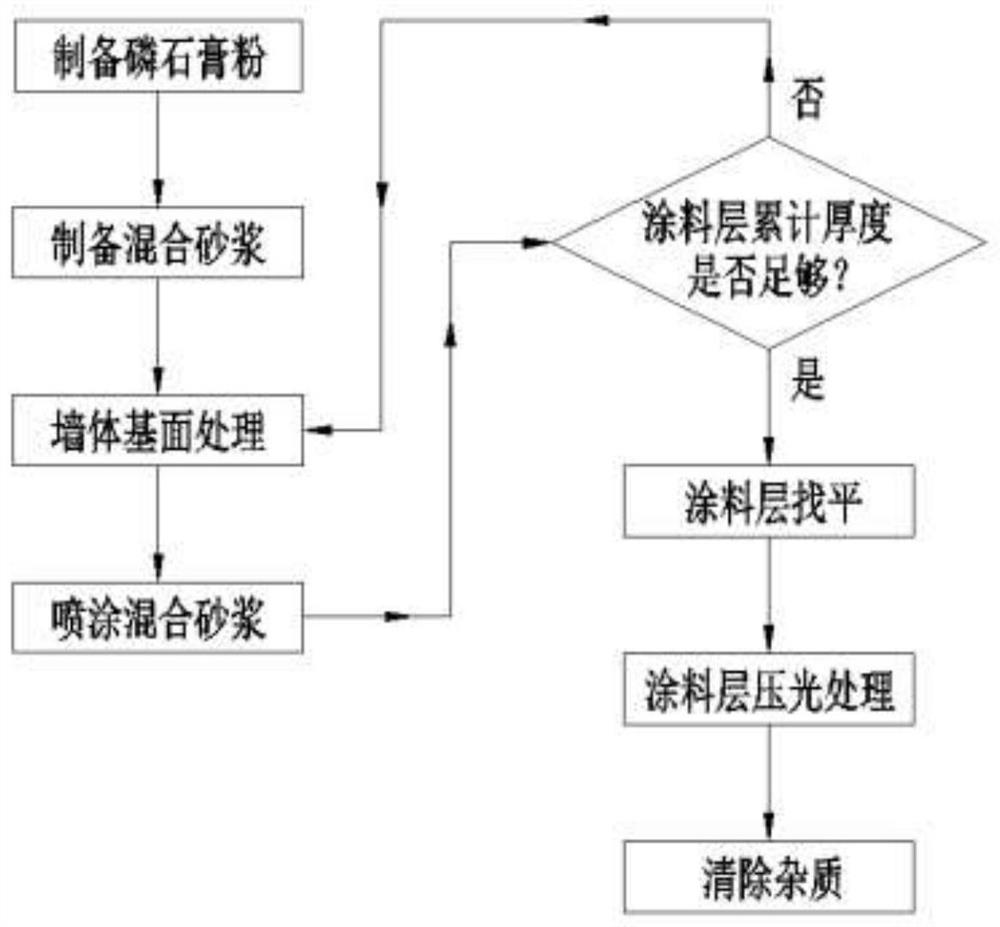

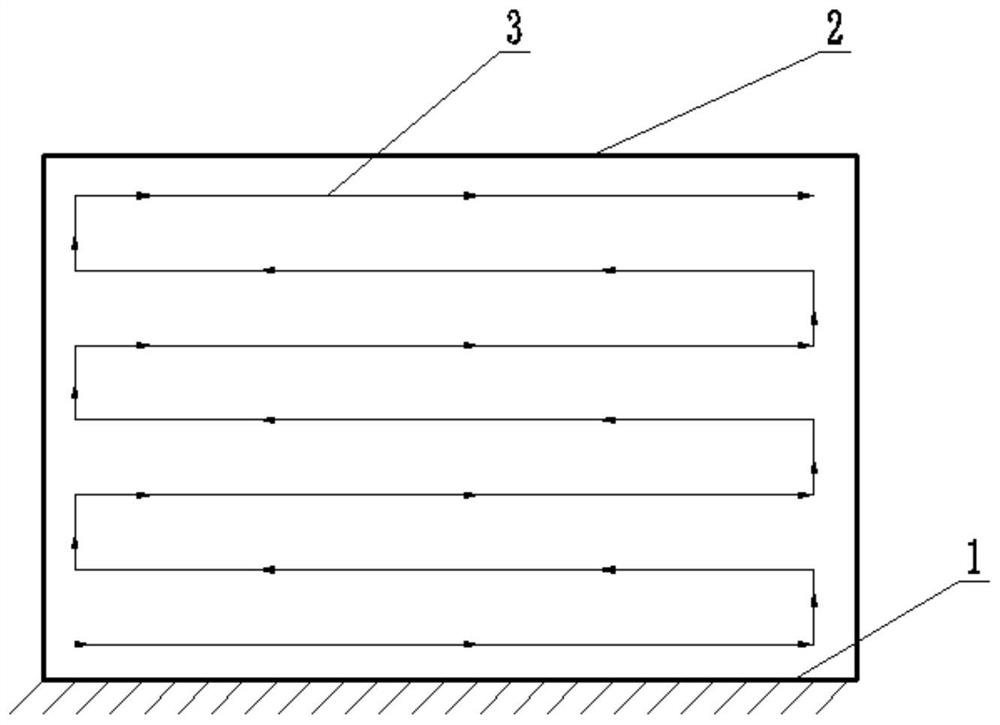

[0045] Such as figure 1 , figure 2 As shown, the present invention provides a kind of phosphogypsum-based mixed mortar wall spraying process, comprising the following steps:

[0046] Step 1: Preparation of phosphogypsum powder: input the phosphogypsum powder containing water into the air dryer for dehydration and drying to obtain phosphogypsum powder. The drying time is 1-4 hours, the drying temperature is controlled at 150-180°C, and the water content of the phosphogypsum powder is ≤ 3%;

[0047] Step 2: Prepare mixed mortar: mix magnesium hydroxide, polyvinyl alcohol, oxalic acid, phosphoric acid, fatty alcohol polyoxyethylene ether sulfuric acid, quartz sand, cement, water and phosphogypsum powder in step 2 at 80°C to Mix and stir evenly at 120°C for 5-10 minutes, then cool to room temperature to prepare mixed mortar;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com