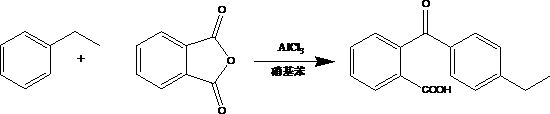

Synthesis method of 2-(4 '-ethylbenzoyl) benzoic acid

A technology of ethyl benzoyl and synthesis method, which is applied in the field of synthesis of 2-benzoic acid, can solve problems such as high chemical oxygen demand of aluminum trichloride wastewater, increased production cost, and difficulty in wastewater treatment, and achieve solvent recovery Difficulty, low product cost, and reduced processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The present embodiment adopts following raw materials, specifically see Table 1:

[0027] Table 1. Composition of raw materials

[0028] serial number raw material name Dosage percentage content 1 ethylbenzene 500g 99.5% 2 Nitrobenzene 75g 99.0% 3 Phthalic anhydride 150g 99.0% 4 Aluminum trichloride 270g 98.5% 5 hydrochloric acid 900g 5%

[0029] The synthetic method of 2-(4'-ethylbenzoyl) benzoic acid comprises the steps:

[0030] 1) In a 1000ml glass reactor, add 500g of ethylbenzene and 75g of nitrobenzene, start stirring, add 150g of phthalic anhydride (phthalic anhydride), start the cooling system, cool the system down to 15°C, and slowly add 270g of trichloro Aluminum, the dosing time is about 1.5h. With the input of aluminum trichloride, the temperature of the system will rise slowly, and the temperature of the control system will rise slowly to 19°C. After adding aluminum trichloride in batches, the rea...

Embodiment 2

[0036] The synthetic method of 2-(4'-ethylbenzoyl) benzoic acid comprises the steps:

[0037] 1) In a 1000ml glass reactor, add 500g of ethylbenzene and 75g of nitrobenzene, start stirring, add 150g of phthalic anhydride (phthalic anhydride), start the cooling system, cool the system down to 15°C, and slowly add 270g of trichloro Aluminum, the dosing time is about 1.5h. With the input of aluminum trichloride, the temperature of the system will rise slowly. The temperature of the control system is not higher than 20°C. After rising to 27°C, the cooling system was turned off, and the state continued for 2 hours to obtain a reaction liquid.

[0038] 2) Add 900g of dilute sulfuric acid with a concentration of 5% into a 2000ml glass reaction kettle, slowly put the reaction material liquid into hydrochloric acid for hydrolysis, control the hydrolysis temperature at 85°C, and the hydrolysis is complete.

[0039] 3) After the hydrolysis is completed, the lower water layer is separate...

Embodiment 3

[0041] In this example, on the basis of the methods in Example 1 and Example 2, one reaction condition was changed to ensure that the remaining reaction conditions remained unchanged, and the reactants (type and amount of acid), system temperature, hydrolysis temperature and hydrolysis time were studied respectively. impact on the product.

[0042] Table 2 records the effect on the product of using dilute hydrochloric acid and dilute sulfuric acid and changing the dosage of dilute hydrochloric acid and dilute sulfuric acid. Wherein group 1 is the experimental result of embodiment 1, and group 2, 3, 4 is to change the consumption of phthalic anhydride, the consumption of nitrobenzene, the consumption of dilute hydrochloric acid respectively on the basis of embodiment 1, group 5 is The experimental result of embodiment 2. It can be seen from the results that the different amounts of reactants will affect the content of 2-(4'-ethylbenzoyl)benzoic acid in the final product.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com