A method of manufacturing a semiconductor device

A technology for semiconductors and devices, applied in the field of semiconductor device preparation, can solve the problems of current leakage of semiconductor devices, uneven deposition of dielectric layers on storage electrodes, etc., and achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

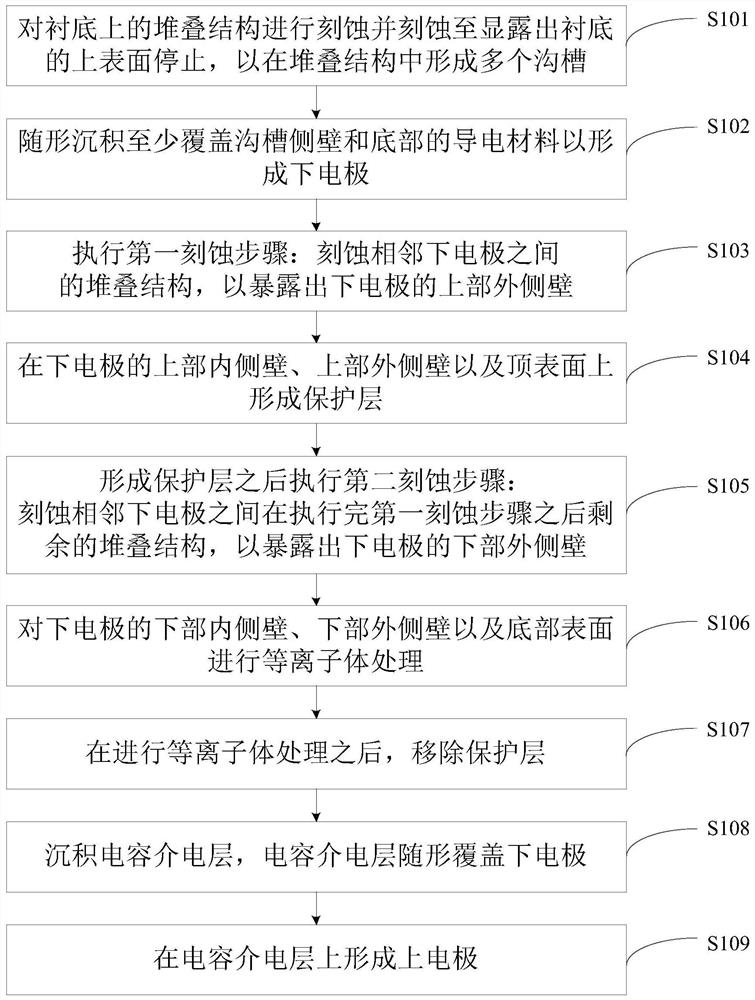

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

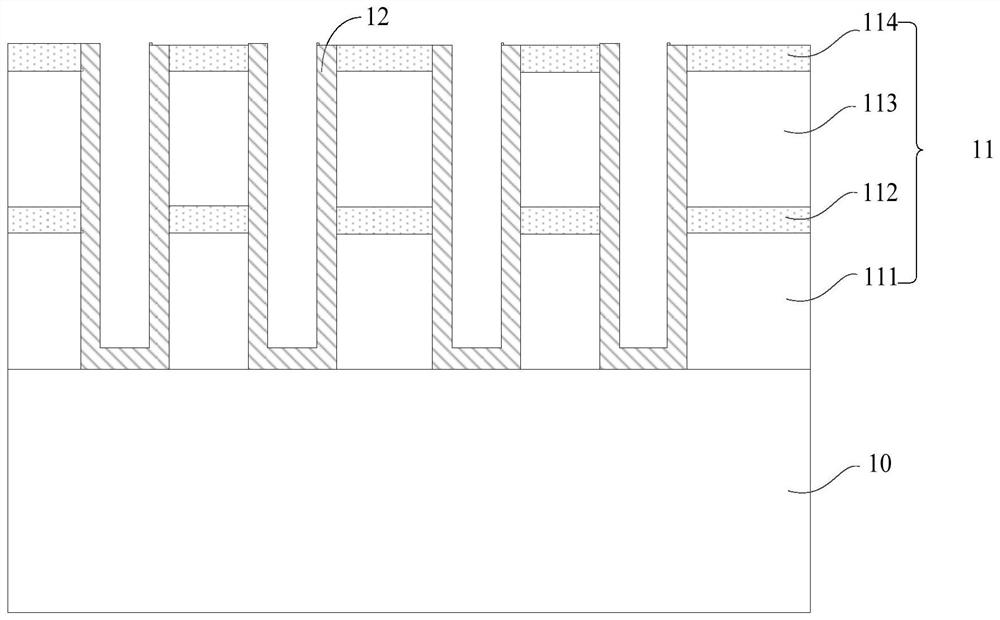

[0069] see Figure 10 as shown, Figure 10 It shows a schematic cross-sectional structure diagram of a semiconductor device provided in the embodiment of the present application. The semiconductor device is made by using the semiconductor device manufacturing method provided in the embodiment of the present application, which includes:

[0070] Substrate 10;

[0071] A plurality of cylindrical lower electrodes 12 located on the substrate 10 and in contact with the substrate 10;

[0072] A capacitive dielectric layer 14 covering the lower electrode 12;

[0073] The upper electrode 15 is located on the capacitor dielectric layer 14 .

[0074]Wherein, the substrate 10 may include Si substrate, Ge substrate, SiGe substrate, SOI (Silicon On Insulator, Silicon On Insulator) or GOI (Germanium On Insulator, Germanium On Insulator) and so on. In other embodiments, the substrate 11 can also be a substrate including other elemental semiconductors or compound semiconductors, such as G...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com