A carbon-coated silicon oxide/g-c 3 n 4 Composite material, preparation method and application thereof

A silicon oxide, composite material technology, applied in nanotechnology, electrochemical generator, nanotechnology and other directions for materials and surface science, can solve the problem of battery capacity and cycle performance decline, material powder falling off, low conductivity and other problems, to achieve the effect of enhancing electron cloud density, improving conductivity, and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

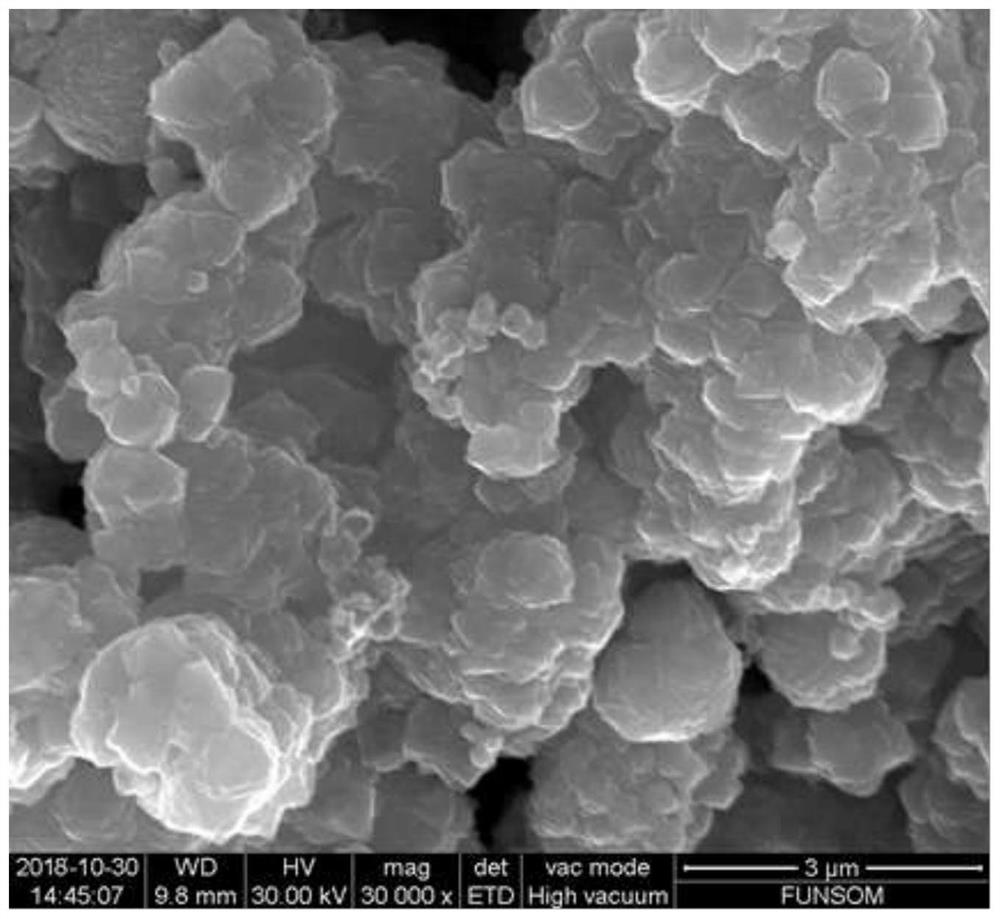

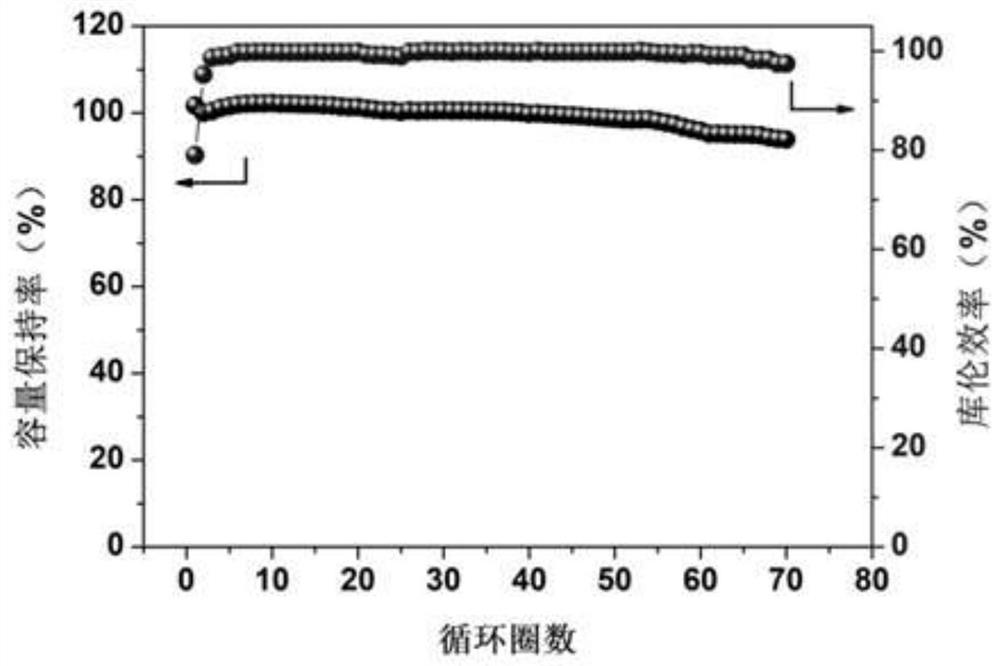

Image

Examples

Embodiment 1

[0035] A carbon-coated silicon oxide / g-C 3 N 4 The preparation method of composite material comprises the following steps:

[0036] S1. Take 10g of urea powder and put it in an alumina crucible, then add 1mL of ammonia water to mix evenly, put it in a muffle furnace with a cover, heat it to 550°C at a speed of 1°C / min, keep calcined for 5h, and take it out after natural cooling Grind to get light yellow powder which is g-C 3 N 4 ;

[0037] S2. Add silicon oxide and glucose into a mortar at a mass ratio of 4:1 for full grinding for 30 minutes, then pour it into a porcelain boat, transfer it to a tube furnace, and feed N 2 , and heated to 600°C at a rate of 10°C / min, kept calcined for 6h, and then naturally cooled to obtain carbon-coated silicon oxide;

[0038] S3, the g-C 3 N 4 Add the carbon-coated silicon oxide to deionized water at a mass ratio of 1:3, stir and mix at 80 °C, then add polyethylene glycol, stir magnetically for 30 min to mix evenly, then suction filter,...

Embodiment 2

[0040] A carbon-coated silicon oxide / g-C 3 N 4 The preparation method of composite material comprises the following steps:

[0041] S1. Take 10g of melamine powder and put it in an alumina crucible, then add 2mL of ammonia water to mix evenly, put it in a muffle furnace with a cover, heat it to 550°C at a speed of 2°C / min, keep calcined for 3 hours, and take it out after natural cooling Grind to get light yellow powder which is g-C 3 N 4 ;

[0042] S2. Add silicon oxide and chitosan into a mortar at a mass ratio of 4:3 for full grinding for 30 minutes, then pour it into a porcelain boat, transfer it to a tube furnace, and feed N 2 , and heated to 600°C at a rate of 10°C / min, kept calcined for 6h, and then naturally cooled to obtain carbon-coated silicon oxide;

[0043] S3, the g-C 3 N 4 Add the carbon-coated silicon oxide to deionized water at a mass ratio of 1:3, stir and mix at 80 °C, then add polyethylene glycol, stir magnetically for 30 min to mix evenly, then sucti...

Embodiment 3

[0047] A carbon-coated silicon oxide / g-C 3 N 4 The preparation method of composite material comprises the following steps:

[0048] S1. Take 10g of melamine powder and put it in an alumina crucible, then add 3mL of ammonia water to mix evenly, put it in a muffle furnace with a cover, heat it to 550°C at a speed of 2°C / min, keep it calcined for 3h, and take it out after natural cooling Grind to get light yellow powder which is g-C 3 N 4 ;

[0049] S2. Add silicon oxide and glucose into a mortar at a mass ratio of 3:1 for full grinding for 30 minutes, then pour it into a porcelain boat, transfer it to a tube furnace, and feed N 2 , and heated to 600°C at a rate of 10°C / min, kept calcined for 6h, and then naturally cooled to obtain carbon-coated silicon oxide;

[0050] S3, the g-C 3 N 4 Add the carbon-coated silicon oxide to deionized water at a mass ratio of 1:3, stir and mix at 80 °C, then add polyethylene glycol, stir magnetically for 30 min to mix evenly, then suction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com