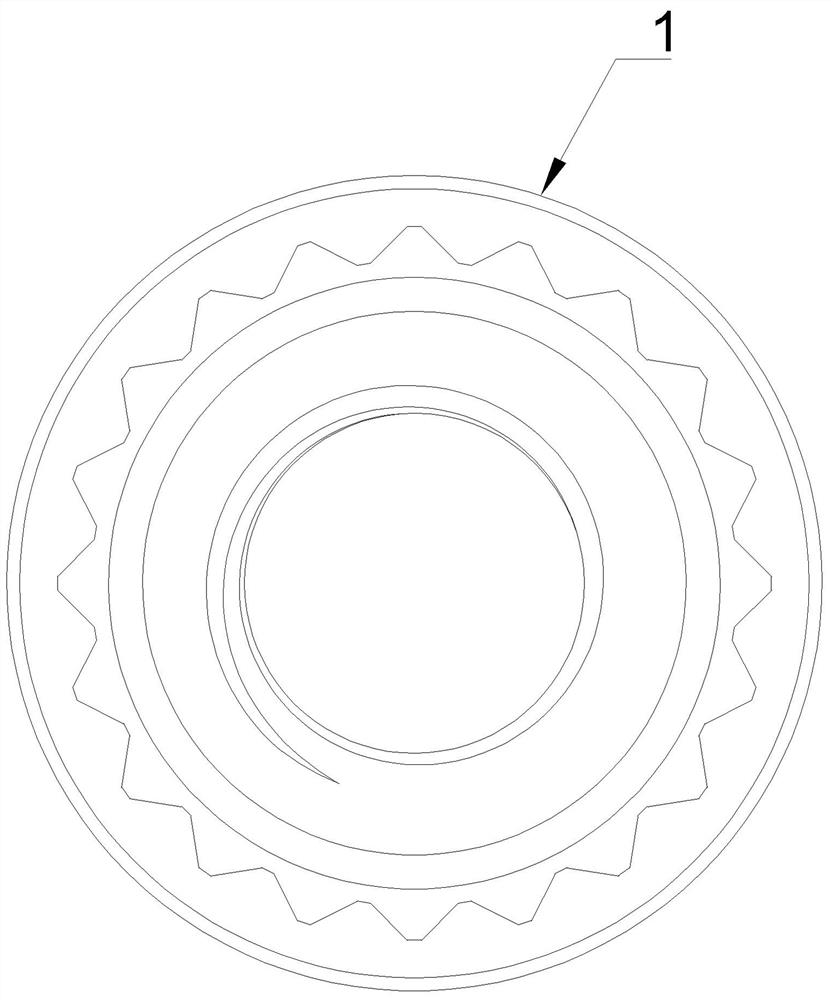

High-strength aluminum rivet nut device and machining method thereof

A technology of pressure riveting nuts and processing methods, which is applied in the direction of nuts, positioning devices, manufacturing tools, etc., can solve problems such as safety hazards, connection failures, and unsatisfactory lightweighting, and achieve high connection strength, avoid connection failures, and significantly reduce weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

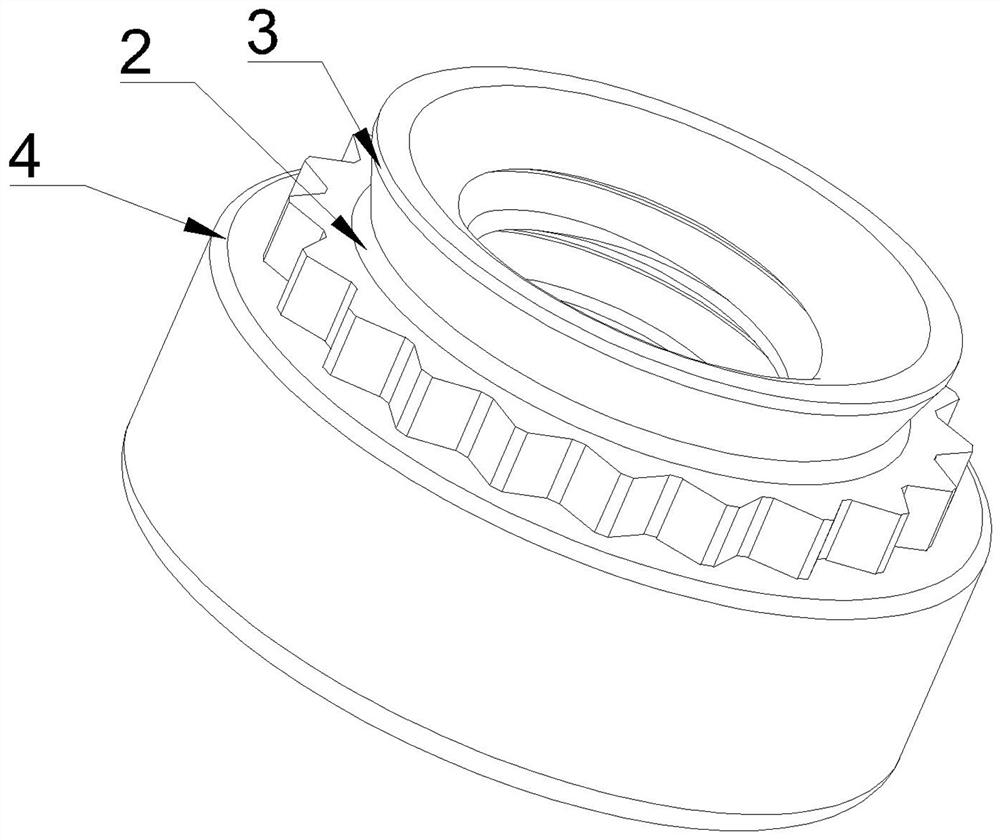

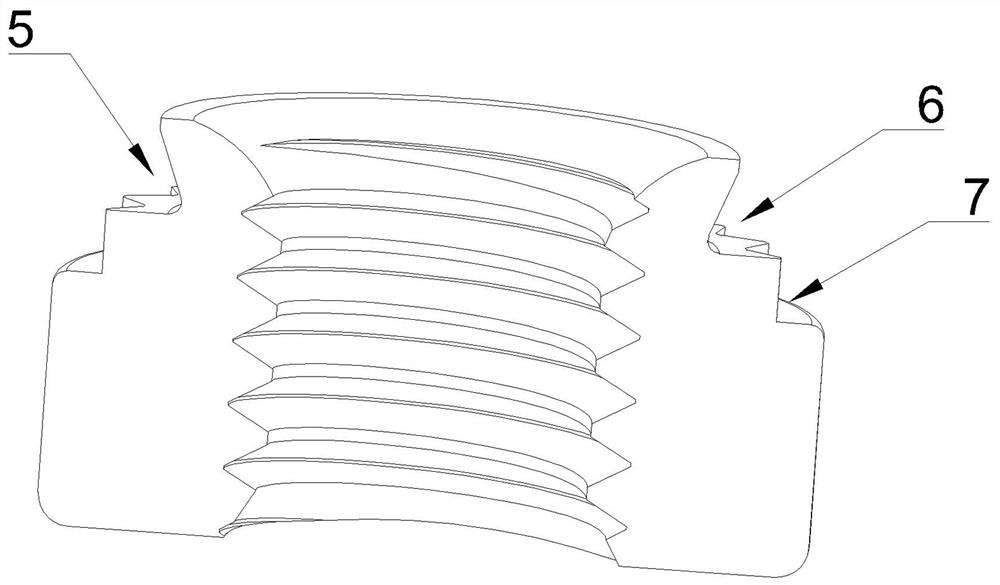

[0035] S1: Select material 2024-T6, the product is M8 riveting nut, the number of structural teeth is 60, and the R angle is 45°;

[0036] S2: Warm heading processing is carried out on a multi-station cold heading machine, the heating temperature of the wire is 250°C, and the warm heading speed is 100 pieces / min. The process includes cutting, shaping, upsetting, heading, positive and negative composite extrusion, punching, etc. , and finally upsetting into a semi-finished blank;

[0037] S3: Tapping on an automatic tapping machine with a processing speed of 60 pieces / minute;

[0038] S4: The surface of the product is cleaned and degreased. Soak the product in the degreasing tank for 15 minutes, then take it out and spin it with a centrifuge at a speed of 1000 rpm for 15 seconds.

[0039] The hardness of the product obtained through the above processing is 130HV, which is used for riveting 5052-H32 aluminum alloy plate, the thickness of the plate is 3mm, the measured anti-rota...

Embodiment 2

[0041] S1: Select material 7075-T6, the product is M10 riveting nut, the number of structural teeth is 45, and the R angle is 60°;

[0042] S2: Warm heading processing is carried out on a multi-station cold heading machine, the heating temperature of the wire is 350°C, and the warm heading speed is 60 pieces / minute. The process includes cutting, shaping, upsetting, heading, positive and negative composite extrusion, punching, etc. , and finally upsetting into a semi-finished blank;

[0043] S3: Tapping on an automatic tapping machine with a processing speed of 50 pieces / minute;

[0044] S4: The surface of the product is cleaned and degreased, and the product is soaked in the degreasing tank for 20 minutes, and then taken out and shaken by a centrifuge at a speed of 1200 rpm for 15 seconds.

[0045] The hardness of the product obtained through the above processing is 175HV, which is used for riveting 6061-T6 aluminum alloy plate, the plate thickness is 3mm, the measured anti-r...

Embodiment 3

[0047] S1: Select material 7A03-T6, the product is M10 riveting nut, the number of structural teeth is 65, and the R angle is 64°;

[0048]S2: Warm heading processing is carried out on a multi-station cold heading machine, the heating temperature of the wire is 320°C, and the warm heading speed is 80 pieces / min. The process includes cutting, shaping, upsetting, heading, front and back composite extrusion, punching, etc. , and finally upsetting into a semi-finished blank;

[0049] S3: Tapping on an automatic tapping machine with a processing speed of 55 pieces / minute;

[0050] S4: The surface of the product is cleaned and degreased, and the product is soaked in the degreasing tank for 18 minutes, then taken out and shaken by a centrifuge at a speed of 1100 rpm for 15 seconds.

[0051] The hardness of the product obtained by the above processing is 165HV, which is used for riveting 6061-T6 aluminum alloy plate, the thickness of the plate is 2.5mm, the measured anti-rotation tor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com