A kind of preparation method of high toughness and high flexibility copper oxide gas desulfurizer

A technology of copper oxide and desulfurizer, applied in chemical instruments and methods, removal of gas pollutants, and other chemical processes, etc. Excellent mechanical properties and flexibility, high flexibility, toughness, strength, and controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

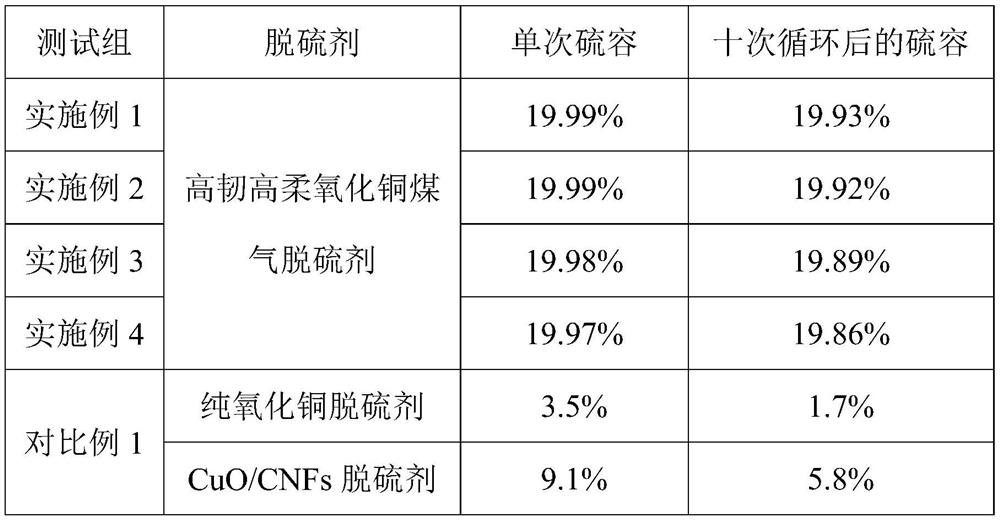

Examples

Embodiment 1

[0026] A preparation method of a high-toughness and high-flexibility copper oxide gas desulfurizer, comprising the following steps:

[0027] A. Preparation of three-dimensional orthogonal structure prefabricated parts: use three-dimensional weaving technology to weave fiber filaments into three-dimensional orthogonal structure prefabricated parts, the number of weaving layers is 15 layers, and the warp and weft yarns of the three-dimensional orthogonal structure prefabricated parts are all carbon fibers Filament, the binding yarn is high silica glass fiber, the warp yarn density is 600 / 10cm, the binding yarn density is 150 / 10cm, and the weft yarn density is 300 / 10cm; the length and The width is 20mm and the thickness is 10mm;

[0028] B. Preparation of impregnation solution: 1.9g copper oxalate powder was dissolved in 20mL water to obtain the impregnation solution;

[0029] C. Equal volume impregnation: immerse the equal volume of the three-dimensional orthogonal structure pr...

Embodiment 2

[0036] A preparation method of a high-toughness and high-flexibility copper oxide gas desulfurizer, comprising the following steps:

[0037] A. Preparation of three-dimensional orthogonal structure prefabricated parts: use three-dimensional weaving technology to weave fiber filaments into three-dimensional orthogonal structure prefabricated parts, the number of weaving layers is 15 layers, and the warp and weft yarns of the three-dimensional orthogonal structure prefabricated parts are all carbon fibers Filament, the binding yarn is high silica glass fiber, the warp yarn density is 600 / 10cm, the binding yarn density is 150 / 10cm, and the weft yarn density is 300 / 10cm; the length and The width is 20mm and the thickness is 10mm;

[0038] B. Preparation of impregnating solution: 3.8g copper oxalate powder was dissolved in 20mL water to obtain impregnating solution;

[0039] C. Equal volume impregnation: immerse the equal volume of the three-dimensional orthogonal structure prefor...

Embodiment 3

[0046] A preparation method of a high-toughness and high-flexibility copper oxide gas desulfurizer, comprising the following steps:

[0047] A. Preparation of three-dimensional orthogonal structure prefabricated parts: use three-dimensional weaving technology to weave fiber filaments into three-dimensional orthogonal structure prefabricated parts, the number of weaving layers is 15 layers, and the warp and weft yarns of the three-dimensional orthogonal structure prefabricated parts are all carbon fibers Filament, the binding yarn is high silica glass fiber; the warp yarn density is 600 / 10cm, the binding yarn density is 150 / 10cm, the weft yarn density is 300 / 10cm, the length and width of the three-dimensional orthogonal structure preform Both are 20mm, and the thickness is 10mm;

[0048] B. Preparation of impregnation solution: 5.7g copper oxalate powder was dissolved in 20mL water to obtain the impregnation solution;

[0049] C. Equal volume impregnation: immerse the equal vo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com