Energy-saving and environment-friendly heat-conducting oil boiler

A heat-conducting oil boiler, energy-saving and environmental protection technology, applied in the field of boilers, can solve problems such as energy waste and low thermal efficiency, and achieve the effects of improving thermal efficiency, increasing heating surface, and increasing the temperature of cold air entering the furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

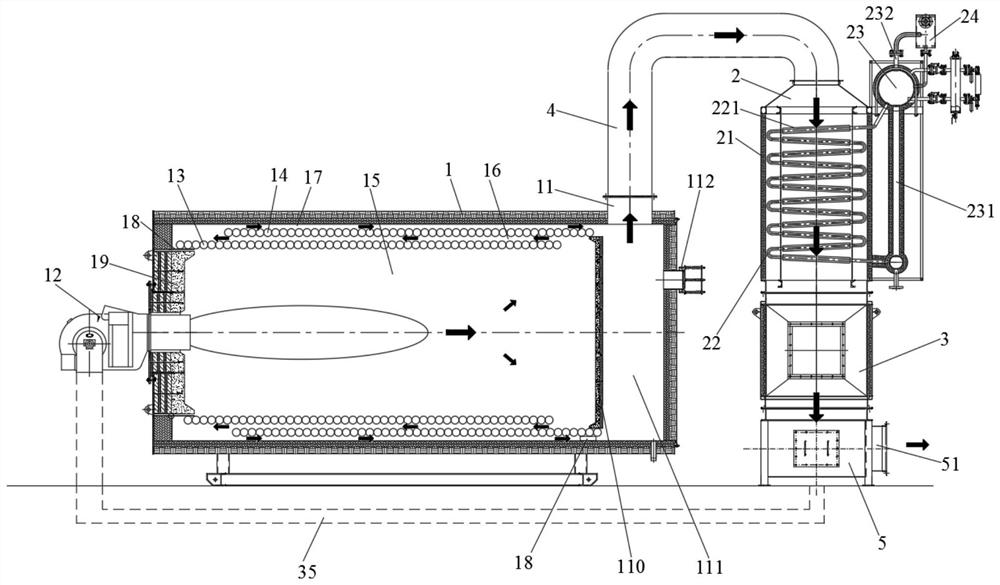

[0042] Such as figure 1 As shown, an energy-saving and environment-friendly heat-conducting oil boiler includes a boiler host 1, a waste heat boiler 2, and an air preheater 3;

[0043] The waste heat boiler 2 includes a vertical body 21; the vertical body 21 is provided with several rows of vertical serpentine heat exchange tubes 22, and the straight pipe sections of the vertical serpentine heat exchange tubes 22 are arranged along the vertical serpentine heat exchange tube. The flow direction of the medium in the heat pipe 22 is inclined upward, and the inclined tube bundle arrangement can make the steam in the steam-water mixture generated in the vertical serpentine heat exchange tube 22 quickly enter the upper steam drum 23, preventing the boiler from running , a large amount of steam accumulates in the vertical serpentine heat exchange tube 22, which affects the safe operation of the boiler; the upper outlet of the vertical serpentine heat exchange tube 22 communicates wit...

Embodiment 2

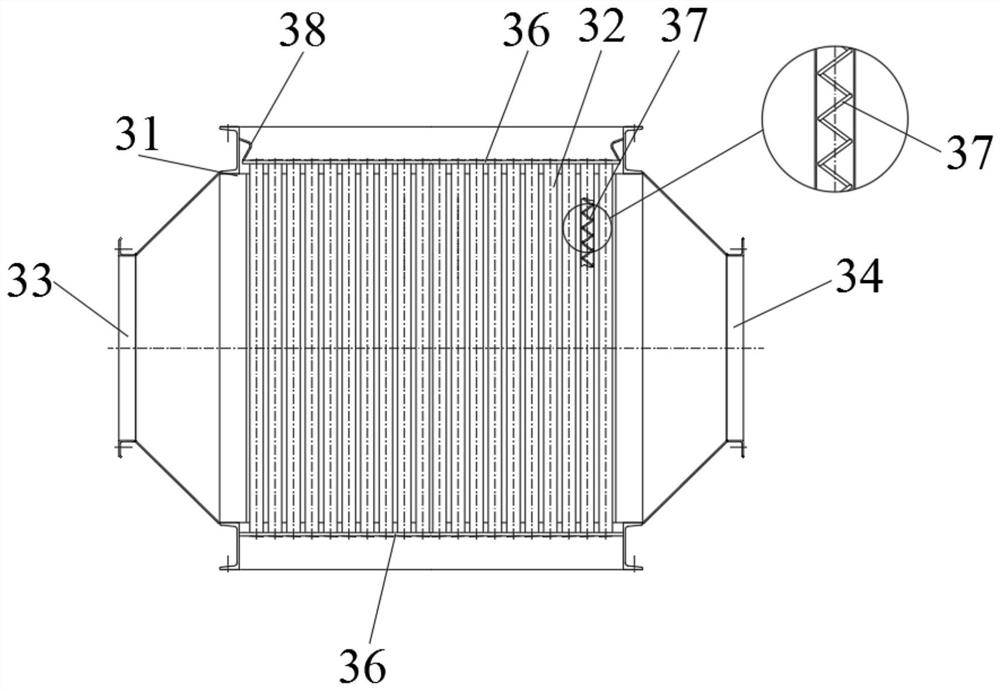

[0056] On the basis of Example 1, such as image 3 As shown, the top and bottom of the air preheater 3 are respectively fixed with horizontal tube sheets 36; the two ends of the vertical heat exchange tubes 32 pass through the corresponding horizontal tube sheets 36 and are fixedly connected with the horizontal tube sheets 36; The lower horizontal tube plate 36 is connected to the external frame 31 , and the upper horizontal tube plate 36 is connected to the external frame 31 through an expansion joint 38 .

[0057] Among them, the top of the vertical heat exchange tube 32 communicates with the flue gas outlet of the waste heat boiler 2, and the bottom of the vertical heat exchange tube 32 communicates with the smoke collection chamber 5; On the other hand, the heat exchange tube 32 also separates the air circulation cavity from the flue gas circulation cavity in the vertical heat exchange tube 32 .

[0058] Preferably, the vertical heat exchange tube 32 is provided with a sp...

Embodiment 3

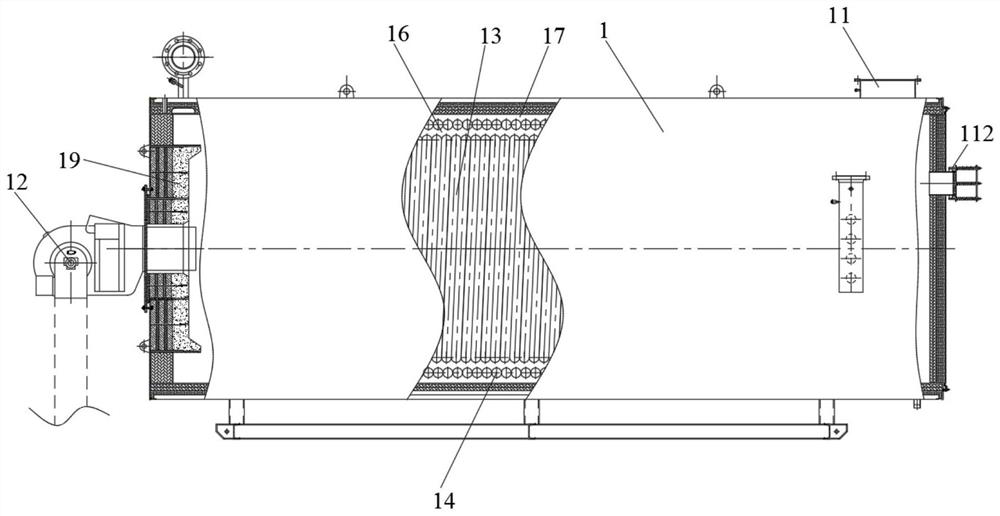

[0061] On the basis of embodiment 1 or embodiment 2, such as figure 2 As shown, the boiler host 1 is arranged in a horizontal arrangement, a burner 12 is arranged at the front of the boiler host 1, and a flue gas outlet 11 is arranged at the tail of the boiler host 1;

[0062] The boiler host 1 is provided with a spiral inner coil 13 and a spiral outer coil 14; The convection channel 16, the second convection channel 17 is surrounded by the spiral outer coil 14 and the shell of the boiler main engine 1; connected, the outlets of the spiral inner coil 13 and the spiral outer coil 14 are respectively communicated with the external oil outlet pipes; in addition, the fixing methods of the spiral inner coil 13 and the spiral outer coil 14 inside the main boiler 1 can be To achieve this, usually the distance tube 18 is fixedly arranged on the casing of the boiler main engine 1 .

[0063] In this application, the main engine 1 of the boiler adopts the spiral coil as the main heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com