Lithium-sulfur battery cathode material and preparation method thereof

A technology for lithium-sulfur batteries and cathode active materials, applied in battery electrodes, lithium batteries, non-aqueous electrolyte batteries, etc., can solve the problems of volume expansion, poor conductivity, and low utilization rate of sulfur in cathode active materials, and achieve convenient operation and equipment Simple, the effect of improving electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

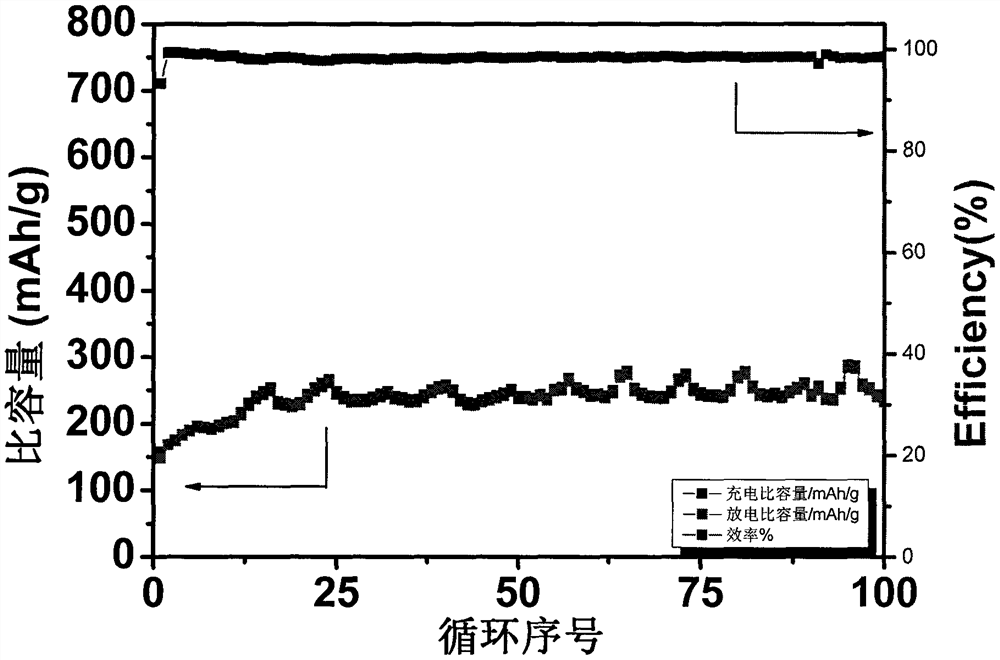

[0015] 0.275g of copper phthalocyanine and 0.225g of elemental sulfur were uniformly mixed in a mortar to obtain a compound. Put 1.5g of zirconia balls and the compound into a 5ml grinding tube, remove the air in the tube, and put it into a micro-vibration ball mill for ball milling. The rotating speed is 3000r / min, and the ball milling time is 1h.

Embodiment 2

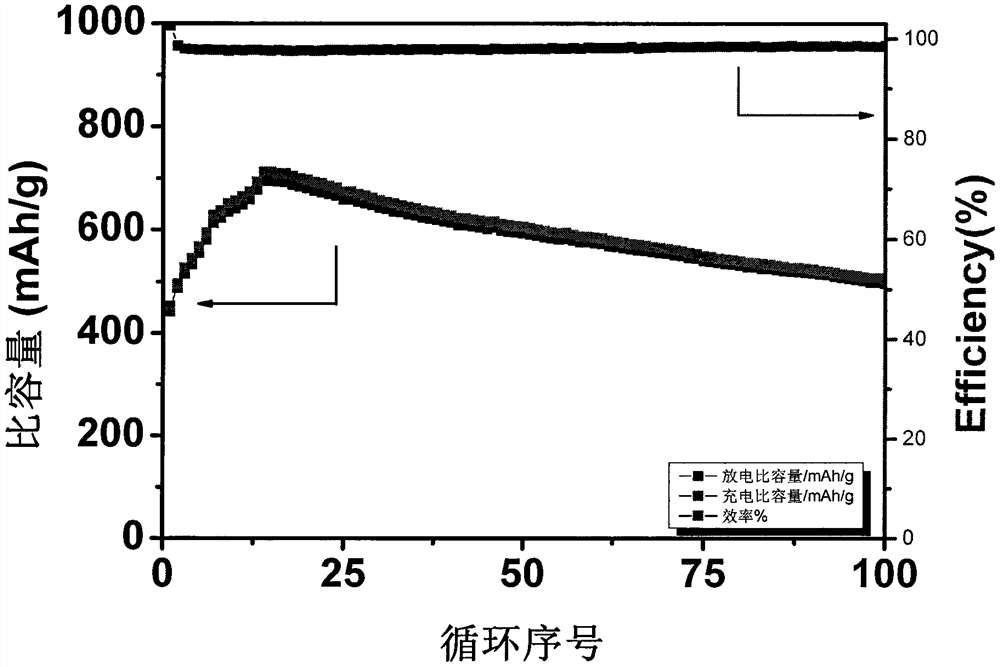

[0017] 0.25g of copper phthalocyanine and 0.25g of elemental sulfur were uniformly mixed in a mortar to obtain a compound. Put 0.5g of zirconia grinding balls and the compound into a 5ml grinding jar, remove the air in the jar, and put it into a micro-vibration ball mill for ball milling. The rotating speed is 2000r / min, and the ball milling time is 2h.

Embodiment 3

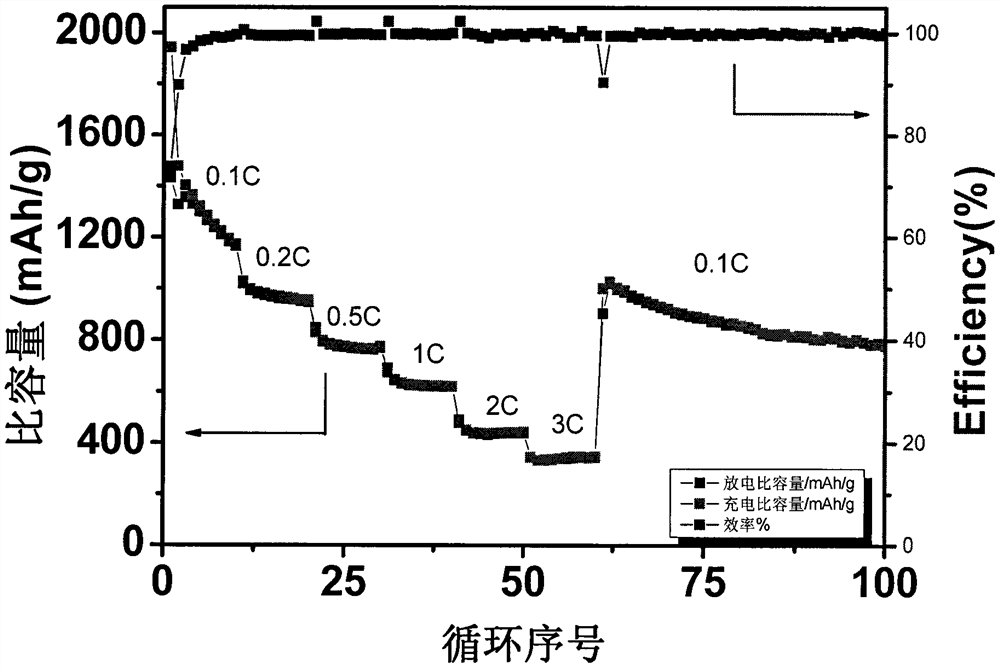

[0019] 0.225g of copper phthalocyanine and 0.275g of elemental sulfur were uniformly mixed in a mortar to obtain a compound. Put 1g of zirconia grinding balls and the compound into a 5ml grinding jar, remove the air in the jar, and put it into a micro-vibration ball mill for ball milling. The rotating speed is 3000r / min, and the ball milling time is 0.5h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com