Preparation method and application of micropore/mesopore/macropore composite pore iron-cobalt bimetallic organic framework material

An organic framework, bimetallic technology, applied in the field of adsorption catalyst preparation, can solve the problems of poor adsorption and catalysis performance of the preparation material, complicated and cumbersome preparation methods, time-consuming and laborious, etc., and achieves excellent adsorption and catalytic performance, good application prospects, and repeatability. Actionable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

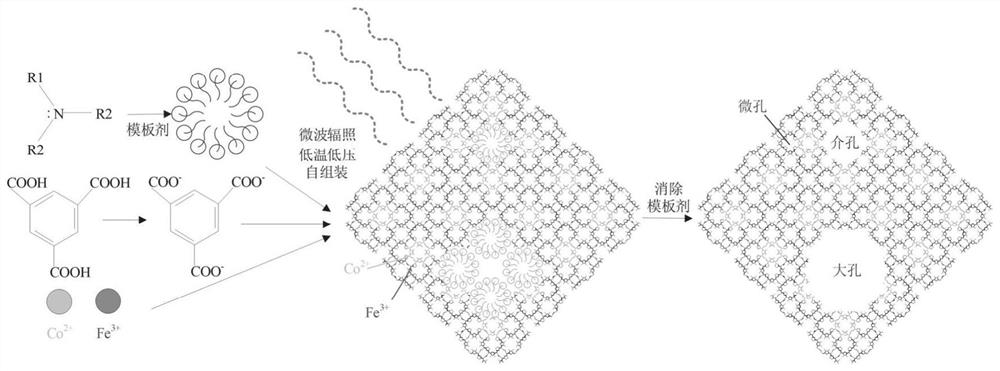

[0034] In view of this, in a specific embodiment of the present invention, a method for preparing a microporous / mesoporous / macroporous composite porous iron-cobalt bimetallic organic framework material is provided, the preparation method comprising:

[0035] S1, dissolving iron salt and cobalt salt into mixed solvent 1 and performing ultrasonic heating treatment to obtain mixed solution A;

[0036] S2, dissolving the pore forming agent and the organic ligand in the mixed solvent 2 and performing ultrasonic heating treatment to obtain a mixed solution B;

[0037] S3, adding the mixed solution B into the mixed solution A, and performing ultrasonic heating treatment to obtain the mixed solution C;

[0038] S4. Perform microwave low-temperature and low-pressure treatment on the mixed solution C; obtain the solid product after purification to obtain the microporous / mesoporous / macroporous composite porous iron-cobalt bimetallic organic framework adsorption material.

[0039] In yet...

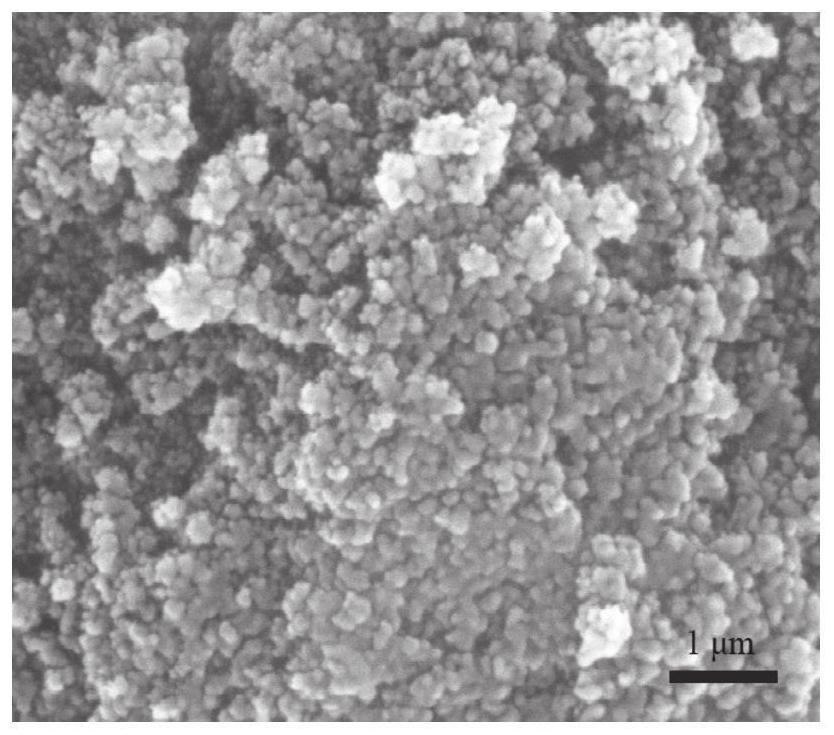

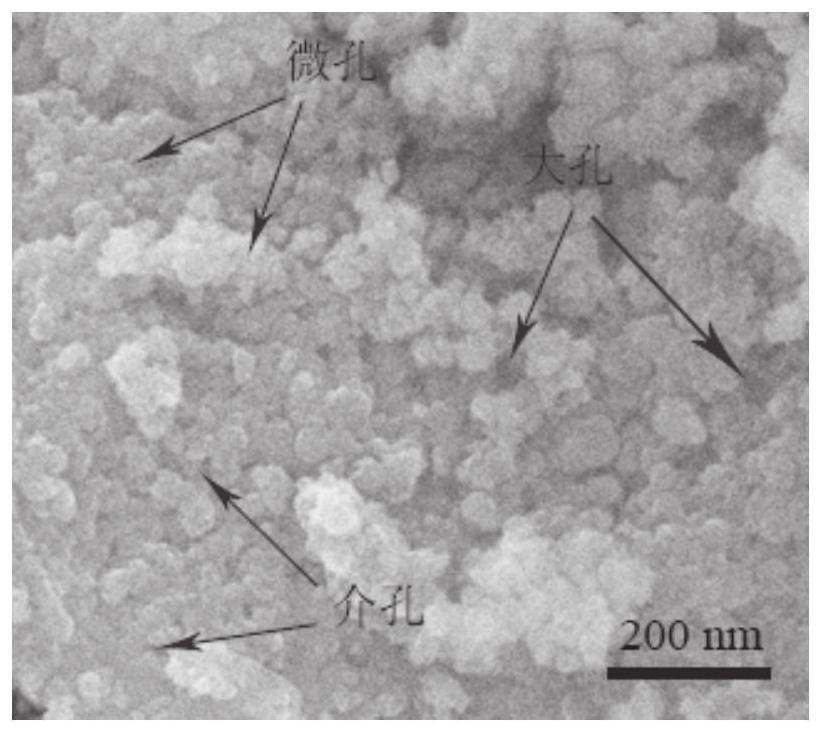

Embodiment 1

[0068] A preparation method of FeCo-MOFs-1, a microporous / mesoporous / macroporous composite porous iron-cobalt bimetallic MOFs adsorption catalyst, comprising the following steps:

[0069] (1) Mix the solvent N,N-dimethylformamide (50mL), ethanol (25mL), and deionized water (25mL) to form a mixed solvent;

[0070] (2) Dissolve ferric nitrate nonahydrate (10mmol), hexahydrate and cobalt nitrate (2mmol) in the mixed solvent of step (1), under the action of ultrasonic power 2kW, frequency 40khz, continue heating in a water bath at 70°C, and stir for 800 rpm / min, the stirring time is 30min, until there is no precipitation, the mixed solution is obtained, which is recorded as solution A;

[0071] (3) The pore-forming agent N,N-dimethyldodecylamine (2.74mmol) and the organic ligand trimesic acid (6.86mmol) were dissolved in N,N-dimethylformamide (75mL) and In a mixed solvent of ethanol (25mL), under the action of ultrasonic power of 2kW and frequency of 40khz, continue heating in a...

Embodiment 2

[0078] A method for preparing a microporous / mesoporous / macroporous composite porous iron-cobalt bimetallic MOFs adsorption catalyst FeCo-MOFs-2, comprising the following steps:

[0079] (1) Mix the solvent N,N-dimethylformamide (75mL), ethanol (25mL), and deionized water (25mL) to form a mixed solvent;

[0080] (2) Ferric chloride hexahydrate (10mmol), hexahydrate and cobalt chloride (1mmol) are dissolved in the mixed solvent of step (1), under the action of ultrasonic power 1.5kW, frequency 40khz, continue heating in a water bath at 60°C, Stir at 700 rev / min for 20 min until there is no precipitation to obtain a mixed solution, which is denoted as solution A;

[0081] (3) The pore-forming agent N,N-dimethyltetradecylamine (1.23mmol) and the organic ligand trimesic acid (6.14mmol) were dissolved in N,N-dimethylformamide (75mL) and In a mixed solvent of ethanol (25mL), under the action of ultrasonic power of 1.5kW and frequency of 40khz, continue to heat in a water bath at 60°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com