Mud-free Fenton coupling multi-module medical wastewater treatment method

A waste water treatment, multi-module technology, applied in the direction of special compound water treatment, water/sludge/sewage treatment, pathogenic microorganism waste water treatment, etc., can solve the problems that cannot meet the requirements of environmental protection, pertinence, stability, and treatment effect Medical wastewater and other problems, to achieve the effects of reducing antibiotic content and biological toxicity, good effluent quality, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

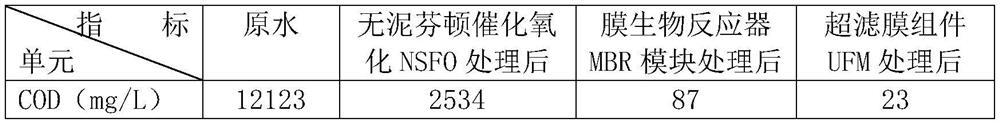

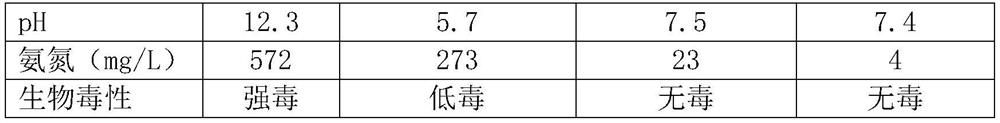

[0029] The method of the present invention is applied in a pharmaceutical manufacturer in Jiangsu to produce high-concentration sewage, and the specific influent water quality is shown in Table 1. The implementation process of sewage treatment is carried out according to the following steps.

[0030] Step 1. The high-concentration sewage generated by the production process first enters the adjustment tank 1, and after buffering and adjustment, the water quality is stabilized and then enters the air flotation tank, and micro-nano bubbles are used to remove large-particle pollutants in the sewage;

[0031] Step 2. The sewage treated in step 1 enters the mud-free Fenton catalytic oxidation tank NSFO, and uses the hydroxyl radicals generated under the catalytic action of hydrogen peroxide to decompose the organic pollutants in the sewage and improve the biodegradability of the sewage;

[0032] Step 3. The sewage flowing out of the mud-free Fenton catalytic oxidation tank NSFO ente...

Embodiment 2

[0040] A pesticide manufacturer in Jiangsu produces pesticide wastewater. The specific influent water quality is shown in Table 2. The reaction steps are the same as in Example 1, and the specific reaction parameters are as follows.

[0041] The specific reaction parameters in this example are: the air flotation technology described in step 1, the residence time is controlled to 25 minutes, and the room temperature is 4° C. during the reaction. In the mud-free Fenton method described in step 2, the waste water enters the mud-free Fenton catalytic oxidation tank after pretreatment, specifically, the circulation time in the reaction tank is 6 hours. The MBR module of the membrane bioreactor described in step 3 adopts the A20-MBR process, the hydraulic retention time is 6 hours, the mixed liquid in the MBR is returned to the anoxic tank, and the reflux ratio is 300%. For the UFM treatment of the ultrafiltration membrane module described in step 4, the operation time is 12 hours,...

Embodiment 3

[0045] An antibiotic manufacturer in Jiangsu produces high-concentration antibiotic and precursor wastewater. The specific influent water quality is shown in Table 3. The reaction steps are the same as in Example 1, and the specific reaction parameters are as follows.

[0046] The specific reaction parameters in this example are: the air flotation technology described in step 1, the residence time is controlled to 30 minutes, and the room temperature is 23° C. during the reaction. In the mud-free Fenton method described in step 2, the waste water enters the mud-free Fenton catalytic oxidation tank after pretreatment, specifically, the circulation time in the reaction tank is 6 hours. The MBR module of the membrane bioreactor described in step 3 adopts the A20-MBR process, the hydraulic retention time is 8 hours, the mixed liquid in the MBR is returned to the anoxic tank, and the reflux ratio is 400%. For the UFM treatment of the ultrafiltration membrane module described in st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com