Preparation method of fluorescent transparent composite material

A technology of composite materials and fluorescent materials is applied in the field of preparation of transparent crab shells, which can solve the problems of non-fluorescence, brittleness, and opaqueness of natural crab shells, and achieve the effect of expanding the scope of application and high light transmittance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

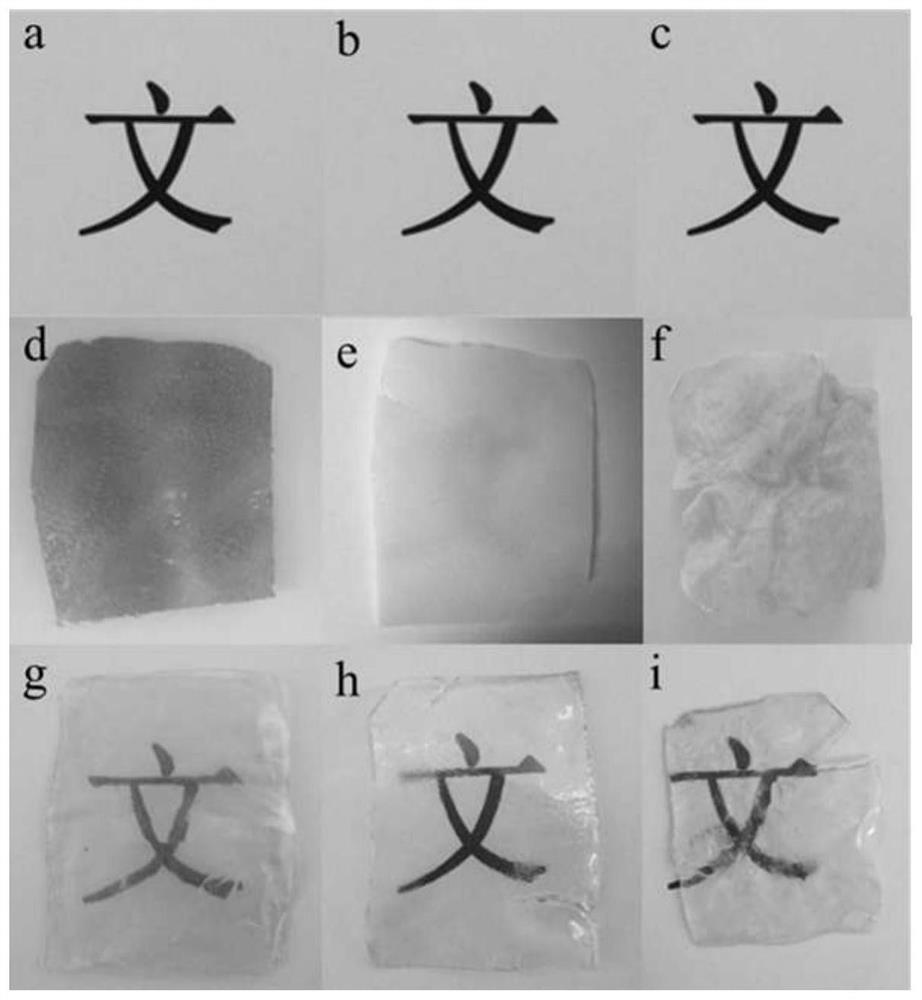

[0028] The preparation steps of the fluorescent transparent composite material of the present invention are as follows:

[0029] (1) Select crab shells or crab shell slices that are intact, clean them, and store them in deionized water for later use.

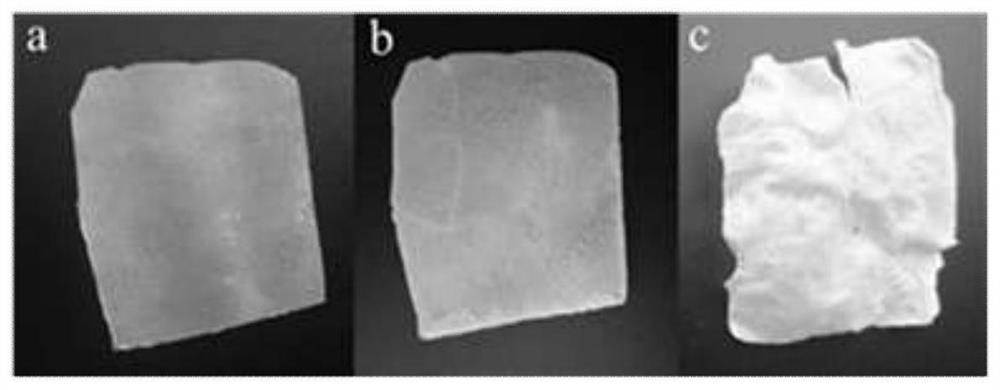

[0030] (2) Use low-concentration acid-base and ethanol solution to soak the whole crab shell or crab shell slices in sequence until the matrix such as calcium carbonate, protein, lipid and pigment is completely removed, and store the treated crab shell in absolute ethanol spare.

[0031] (3) After the phosphor is uniformly dispersed in the polymer monomer through thermomechanical stirring, polymerization or curing agent is added for curing.

[0032] (4) Take out the processed crab shell, immerse it in partially polymerized polymer, and vacuum and keep the pressure in a vacuum drying oven for 15 minutes, repeat three times, take out the crab shell and wrap it with tin foil, and then perform constant temperature curing.

[0033] The crab s...

specific Embodiment 1

[0039] Preparation of transparent crab shell flakes and crab shell with resin (EP) as polymer matrix

[0040] (1) Select crab shells or crab shell slices that are intact, clean them, and store them in deionized water for later use.

[0041] (2) Place the crab shells or crab shell pieces in a beaker, and soak them in a dilute HCl solution for 12 hours, repeat more than 2 times until the CaCO is completely removed 3 ; At 55℃, CaCO will be removed 3 The crab shells or crab shell pieces are soaked in the prepared NaOH dilute solution for 2 hours, and repeated more than 4 times to completely remove the protein and lipids in the crab shells; at room temperature, use absolute ethanol to soak the above-mentioned processed Crab shell for more than 12 hours, until the pigment in the crab shell is removed and stored in absolute ethanol for later use.

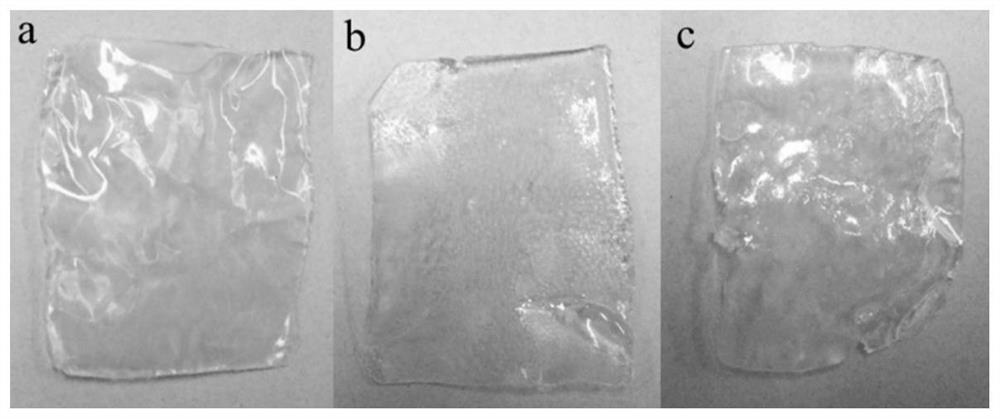

[0042] (3) Add epoxy resin and curing agent with a mass ratio of 3:1 into the mold and mix them evenly. The processed crab shells and crab shell...

specific Embodiment 2

[0044] Preparation of transparent crab shell sheet with methyl methacrylate as polymer matrix

[0045] The processing method for removing the matrix inside the crab shell is the same as the steps (1) and (2) in Example 1.

[0046] Weigh 0.02g of benzoyl peroxide and 20g of methyl methacrylate into a closed Erlenmeyer flask, heat in a water bath at 85°C until the solution has a significant viscosity change, quickly take out the Erlenmeyer flask and put it in ice water, and continue Shake to accelerate cooling to obtain prepolymerized methyl methacrylate. Put the processed crab shell pieces into a small beaker, immerse the crab shell pieces with pre-polymerized methyl methacrylate, and then put the small beaker into a vacuum drying oven. When the vacuum degree is 0.03MPa, keep the pressure for 15 minutes. Repeat this step 3 times, and finally keep the pressure at a vacuum of 0.05MPa for 24h. Use tweezers to take out the completely infiltrated crab shell pieces, wrap them in tin foi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com