Method for preparing chain-link-shaped gold nanowire through electrochemical method

A gold nanowire and electrochemical technology, which is applied in the field of electrochemical preparation of chain-shaped gold nanowires, can solve the problems of difficult control of the morphology of gold nanowires, environmental poisoning, complicated process, etc., and achieves easy product separation and less impurities. , The effect of the simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

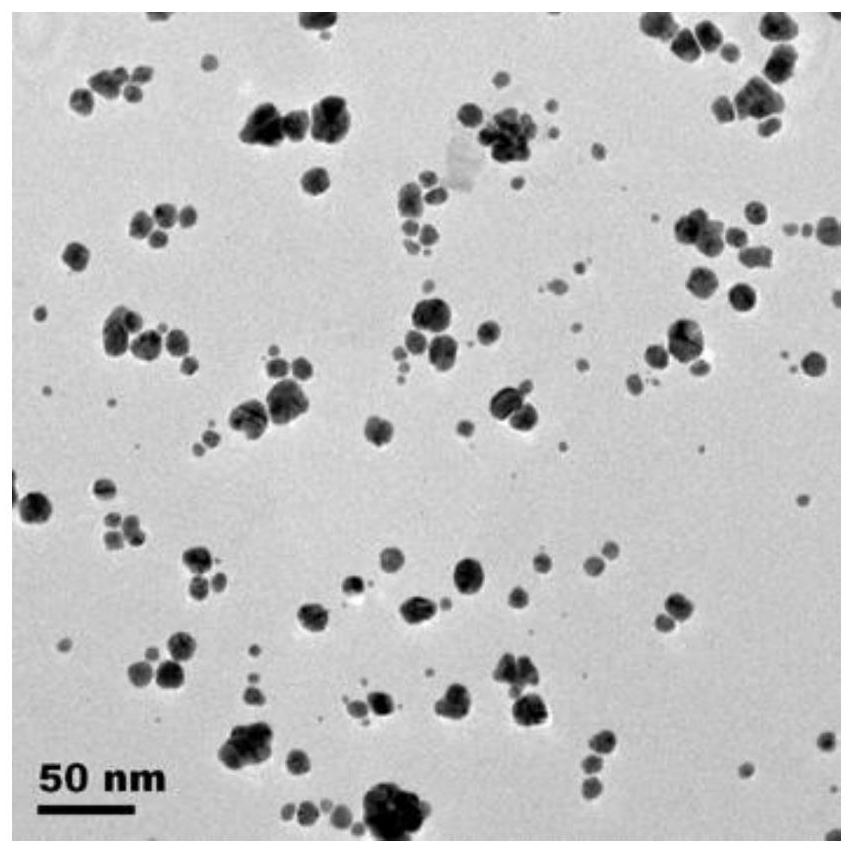

[0025] Embodiment 1 prepares spherical gold nanoparticles

[0026] Containing a certain amount of polyethylene glycol, sodium carboxymethylcellulose, sodium lauryl sulfate and chloroauric acid (HAuCl 4 ) to form a mixed solution, then place the mixed solution in a reaction tank, heat to 40°C, and perform a reduction reaction for 3 hours. The final concentration of each component in the mixed solution is: polyethylene glycol 3g / L, sodium carboxymethyl cellulose (CMC) 1.5g / L, sodium lauryl sulfate 3g / L, chloroauric acid (HAuCl 4 )1mol / L;

[0027] After the reduction reaction is completed, the reaction solution is centrifuged at 12,000 r / min in a high-speed centrifuge to separate the product, and finally the product precipitate is washed three times with water to obtain spherical gold nanoparticles.

Embodiment 2

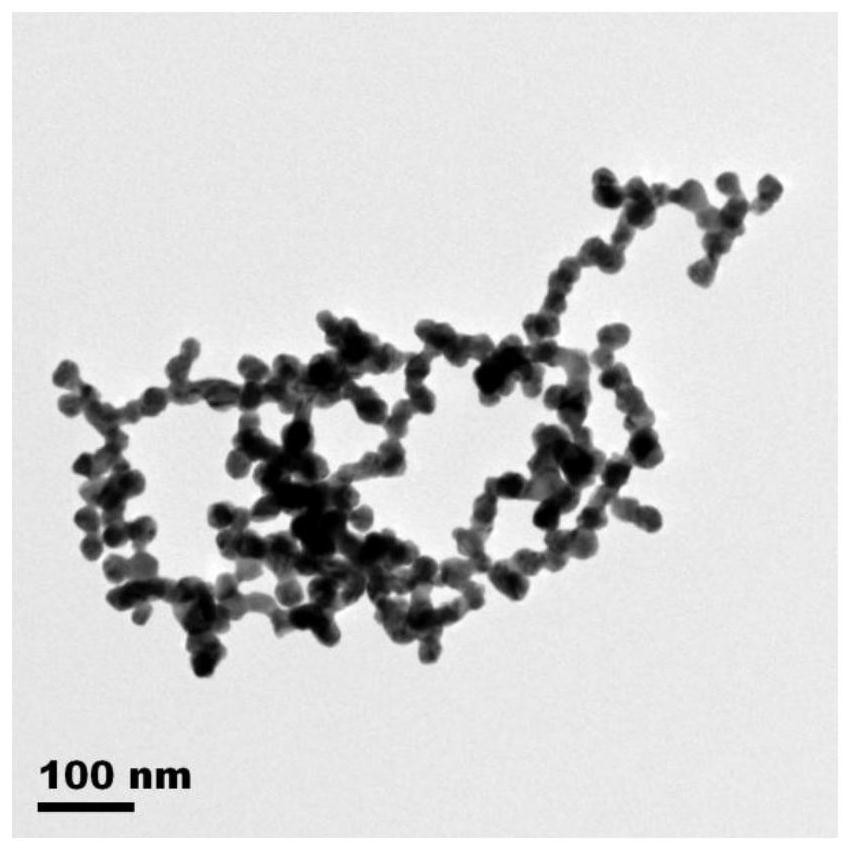

[0028] Example 2 Preparation of chain-link gold nanowires 1

[0029] Containing a certain amount of polyethylene glycol, sodium carboxymethylcellulose, sodium lauryl sulfate and chloroauric acid (HAuCl 4 ) to form a mixed solution, and then place the mixed solution in a reaction tank, heat it to 40°C, and perform a reduction reaction for 3 hours at a DC voltage of 1.5V (0.5A). The final concentration of each component in the mixed solution is: polyethylene glycol Alcohol 2g / L, sodium carboxymethylcellulose (CMC) 0.5g / L, sodium lauryl sulfate 2g / L, chloroauric acid (HAuCl 4 )0.5mol / L;

[0030] After the reduction reaction is completed, the reaction solution is centrifuged at 10,000 r / min in a high-speed centrifuge to separate the product, and finally the precipitated product is washed three times with water to obtain chain-link gold nanowires 1 .

Embodiment 3

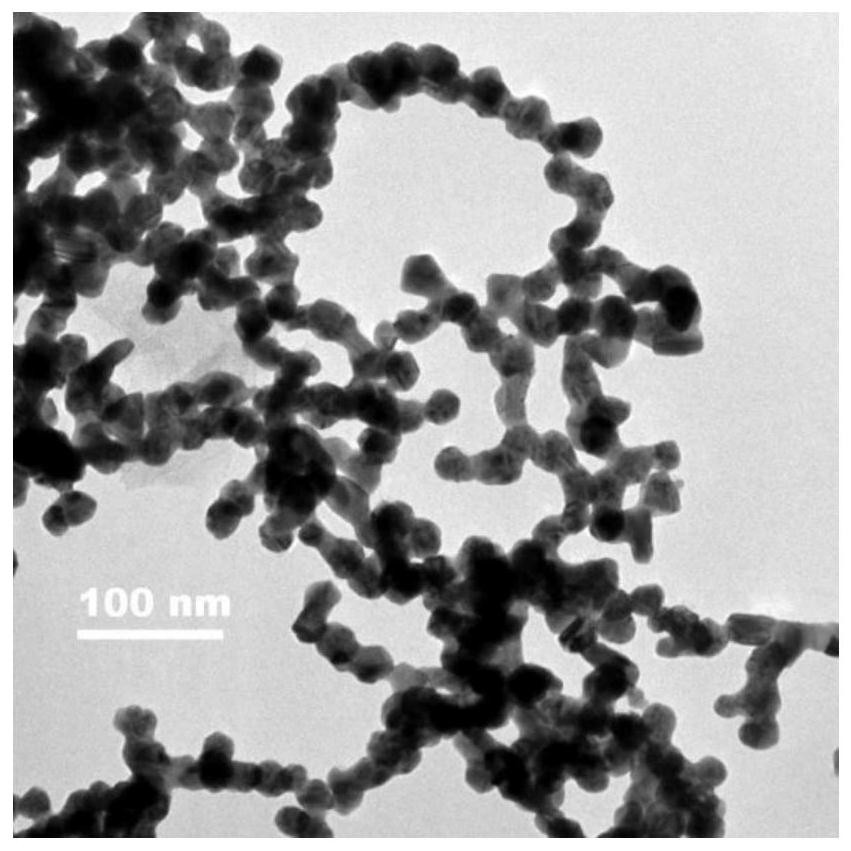

[0031] Example 3 Preparation of chain-link gold nanowires 2

[0032] Containing a certain amount of polyethylene glycol, sodium carboxymethylcellulose, sodium lauryl sulfate and chloroauric acid (HAuCl 4 ) to form a mixed solution, and then place the mixed solution in a reaction tank, heat it to 40°C, and perform a reduction reaction for 3 hours at a DC voltage of 10V (0.5A). The final concentration of each component in the mixed solution is: polyethylene glycol 2g / L, sodium carboxymethylcellulose (CMC) 0.5g / L, sodium lauryl sulfate 2g / L, chloroauric acid (HAuCl 4 )0.2mol / L;

[0033] After the reduction reaction is completed, the reaction solution is centrifuged at 10,000 r / min in a high-speed centrifuge to separate the product, and finally the precipitated product is washed three times with water to obtain chain-link gold nanowires 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com