Graphene-sensitized optical fiber lactic acid sensor and preparation method thereof

A graphene and sensor technology, applied in the field of sensors, can solve problems such as inability to complete high-precision lactic acid concentration measurement, insignificant changes in discrimination, insensitive lactic acid detection, etc., and achieve good linear fitting, repeatability, and sensitivity High and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

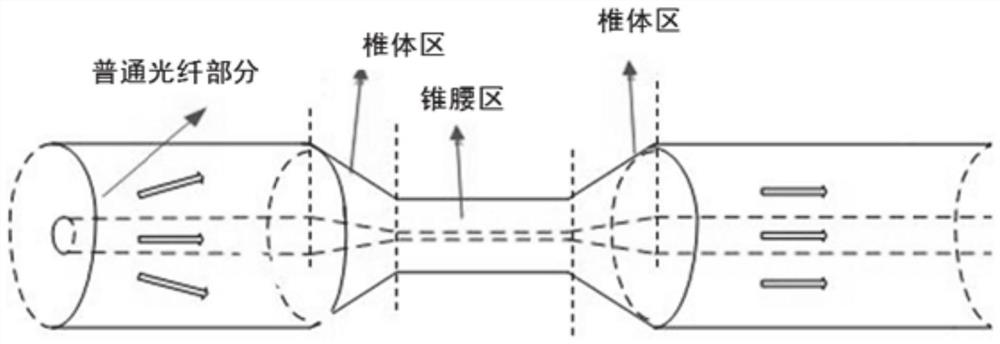

[0029] This embodiment provides a graphene-sensitized optical fiber lactate sensor, comprising: an optical fiber and a nickel coating; a graphene layer is grown in the polished region of the optical fiber after melting and tapering, and the graphene layer is coated everywhere. Nickel plating.

[0030] In this embodiment, an optical fiber is an abbreviation for optical fiber, which is a fiber made of glass or plastic and can be used as a light transmission tool. Generally, the core is surrounded by a glass envelope with a lower refractive index than the core.

[0031] In this embodiment, the polishing of the optical fiber includes cross-section polishing and side polishing. The cross-section polished optical fiber is made by polishing various optical fiber slopes, tapers, etc. made of bare optical fibers; the side polished optical fiber is on a common communication optical fiber. Using optical micromachining technology, the optical fiber made by polishing the cylindrical optica...

Embodiment 2

[0073] This embodiment provides a method for preparing a graphene-sensitized optical fiber lactate sensor, comprising:

[0074] After the optical fiber is fused and tapered, graphene is grown in the polished area, and the graphene oxide layer is obtained through oxidation treatment;

[0075] A nickel plating solution is prepared from a nickel sulfate solution and a reducing agent solution, and the graphene oxide layer of the optical fiber is soaked in the nickel plating solution.

[0076] In this embodiment, after the single-mode optical fiber is tapered, graphene is directly grown in the polished region of the optical fiber by a chemical deposition (CVD) method, and graphene oxide is produced by a Hummers oxidation method.

[0077] In this embodiment, sodium acetate, sodium citrate and sodium hypophosphite were added to the nickel sulfate solution, and an appropriate amount of ammonia was added to adjust the pH value of the solution to about 10 to obtain an electroless platin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com