Kitchen waste resource centralized treatment system and treatment process

A technology for centralized processing of kitchen waste, applied in the field of centralized processing technology and system for the recycling of kitchen waste, can solve the problems of low single-unit processing capacity, secondary pollution, and low degree of resource utilization of microbial treatment technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

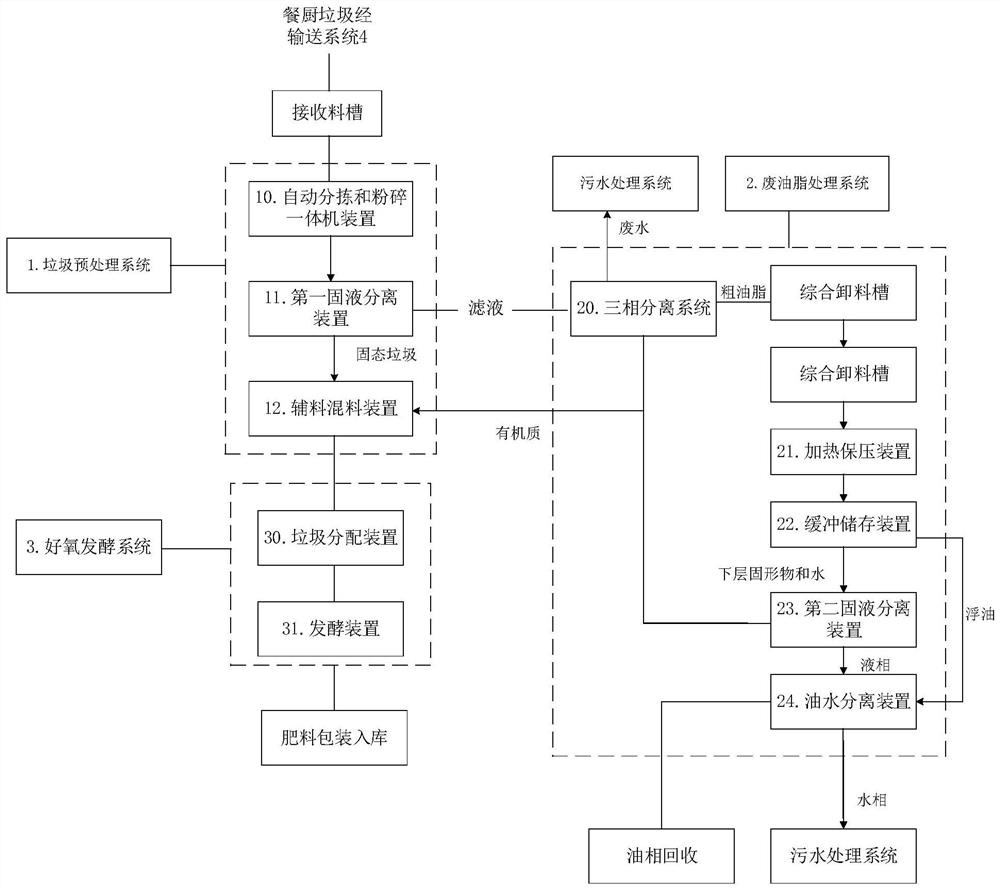

[0028] This embodiment provides a centralized treatment system for resource utilization of food waste, refer to figure 1 As shown, the treatment system includes: a garbage pretreatment system 1, a waste oil treatment system 2, an aerobic composting system 3, and a system for transporting food waste to the garbage pretreatment system 1, waste oil treatment system 2, aerobic Conveyor system 4 of composting system 3 .

[0029]The garbage pretreatment system 1 includes an automatic sorting and crushing integrated machine device 10 , a first solid-liquid separation device 11 , and an auxiliary material mixing device 12 . The kitchen wet garbage collected centrally is sent to the automatic sorting and crushing integrated machine device 10 through the conveying system 4. The main function of the automatic sorting and crushing integrated machine device 10 is to remove unprocessable plastics from the kitchen waste. Products, magnetic metal products, etc. are removed from overseas to r...

Embodiment 2

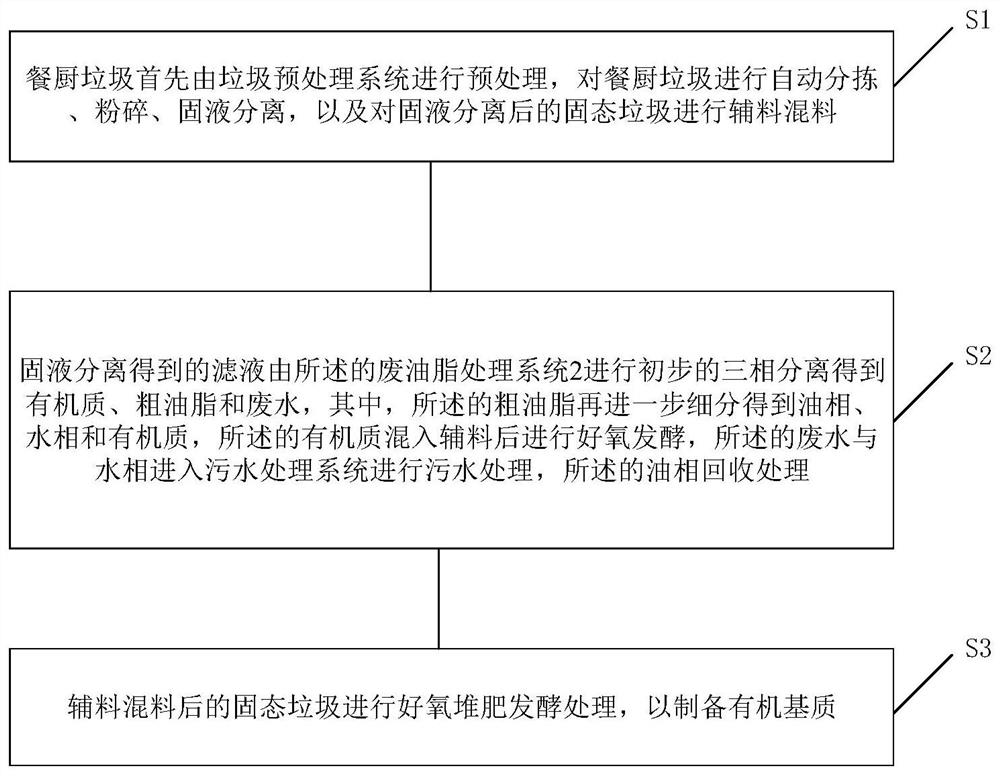

[0039] This embodiment provides a process for resourceful treatment of food waste, which is processed using the centralized treatment system for resourceful food waste described in Example 1, see figure 2 , the treatment process includes:

[0040] S1 Food waste is first pretreated by the waste pretreatment system 1, automatically sorting, crushing, solid-liquid separation of food waste, and mixing auxiliary materials for solid waste after solid-liquid separation;

[0041] S2 The filtrate obtained by solid-liquid separation is subjected to preliminary three-phase separation by the waste oil treatment system 2 to obtain organic matter, crude oil and waste water, wherein the crude oil is further subdivided to obtain oil phase, water phase and organic matter, The organic matter is mixed with auxiliary materials to carry out aerobic fermentation, the waste water and water phase enter the sewage treatment system for sewage treatment, and the oil phase is recovered and treated;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com