Preparation method for pure solid-phase synthesis of salmon calcitonin

A salmon calcitonin and solid-phase synthesis technology, which is applied to the preparation method of peptides, calcitonin, chemical instruments and methods, etc., can solve the problems of long process synthesis cycle, increased production cost, increased raw material input, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The abbreviated meanings of the reagents involved in the present invention are as follows:

[0038]

[0039] The corresponding protected amino acid comparison table and the manufacturer of the amino acid used in the present invention are as follows:

[0040]

[0041]

Embodiment 2

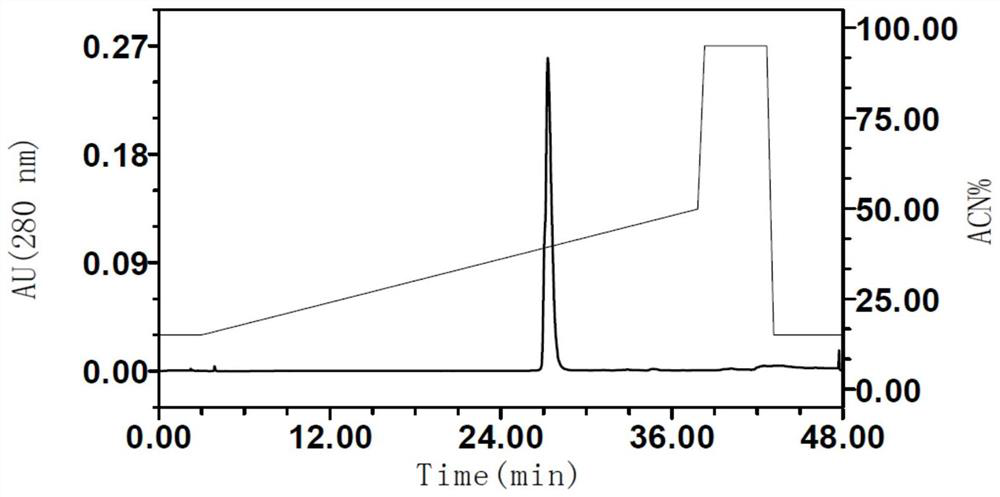

[0043] A preparation method for solid-phase synthesis of salmon calcitonin, comprising the steps of:

[0044] (1) preparation of calcitonin deprotected docosopeptide resin

[0045]Using amino resin as the starting material, Fmoc-protected amino acids as monomers, and HOBT / HATU as condensation reagents, the Fmoc protection groups are sequentially removed in the peptide synthesis column, and the corresponding amino acids are coupled one by one to obtain the deprotected three Dodecapeptide resin; wherein, in the amino acid coupling step, different coupling times are designed according to the difficulty of synthesis of each amino acid;

[0046] (2) Preparation of crude reduced salmon calcitonin

[0047] Add a cleavage reagent to the deprotected docosopeptide resin to cut the peptide, then add ether to precipitate, and collect the precipitate to obtain the crude reduced salmon calcitonin;

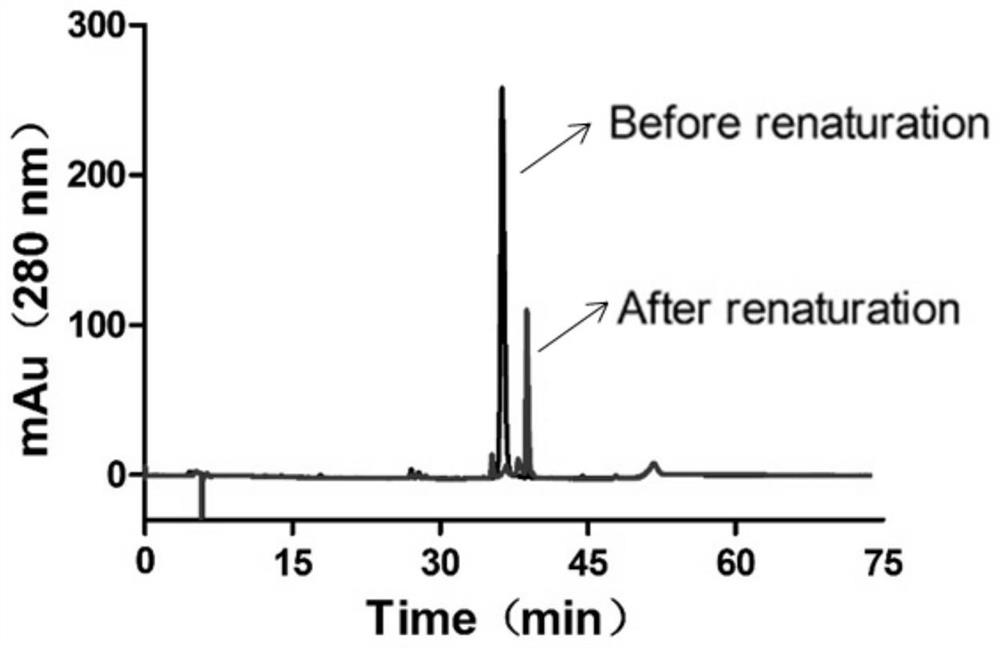

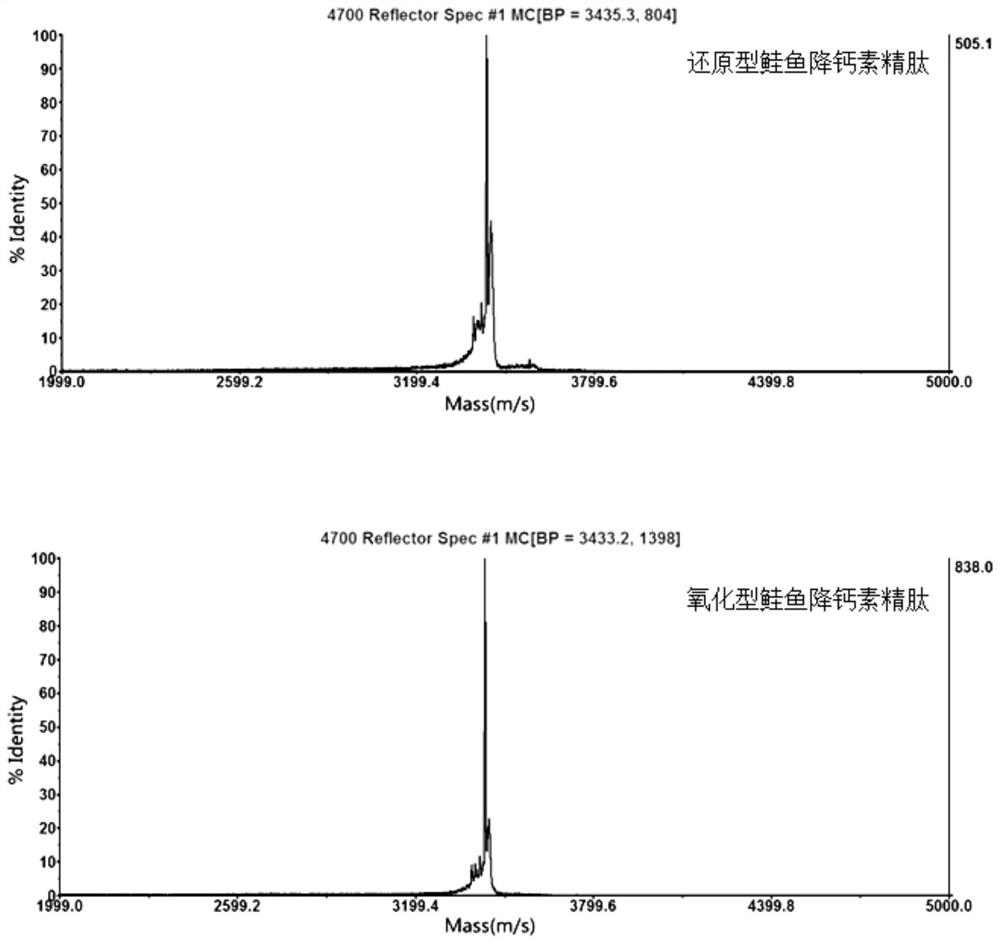

[0048] (3) Refolding

[0049] Firstly, the crude product of reduced salmon calcitonin is ...

Embodiment 3

[0053] Taking the synthesis of 0.1mM salmon calcitonin as an example, this example elaborates the specific steps for preparing the deprotected docosopeptide resin, as follows:

[0054] (1) Weigh 0.1mM, 0.32mmol / g Rink Amide Resin, 4-fold excess amino acid and 5-fold excess HOBT / HATU condensation reagent as the subsequent reaction system of a couple of coupled amino acids, and configure 20% of Piperidine and 5% N-methylmorpholine (both by volume with DMF).

[0055] (2) Weigh 0.32g of Rink Amide Resin with a degree of substitution of 0.32mmol / g and soak in 2-3mL of DMF in the synthesis column for 30min to make it fully expanded, and then use a vacuum pump to filter out the DMF.

[0056] (3) Add 2-3 mL of 20% piperidine to the puffed resin to deprotect it for 7 minutes, shake it on a rotary mixer every 2 seconds, filter out the piperidine, and then add an appropriate amount of 20% piperidine for the second step. The second deprotection was carried out for 8 minutes, during which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com