Large-diameter tungsten bar annealing device and annealing process

An annealing device and annealing process technology, applied in the direction of manufacturing tools, heat treatment equipment, furnaces, etc., can solve problems such as dimensional instability, part chipping, splitting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

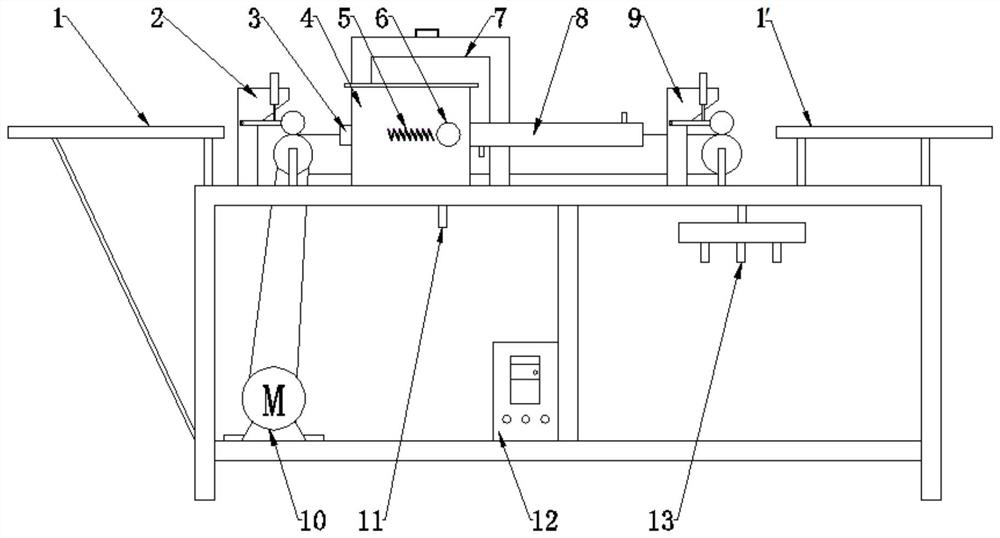

[0052] In embodiment 1, use the large-diameter tungsten rod annealing device of the present invention and annealing process to diameter be The potassium-containing tungsten rods are annealed.

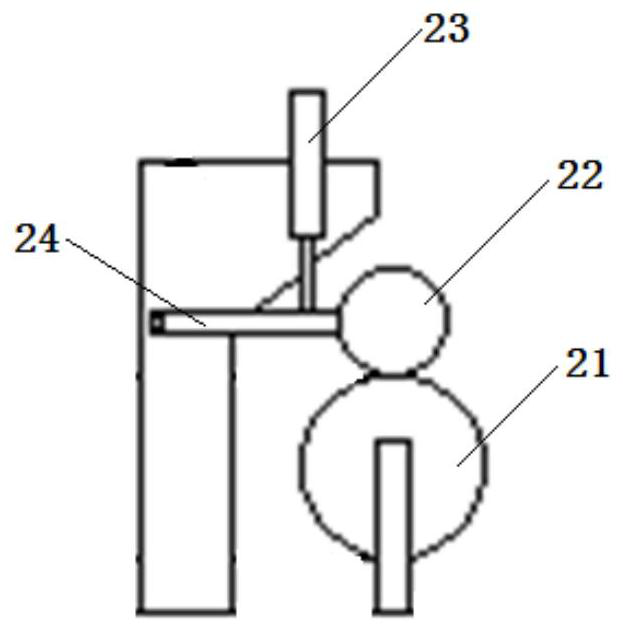

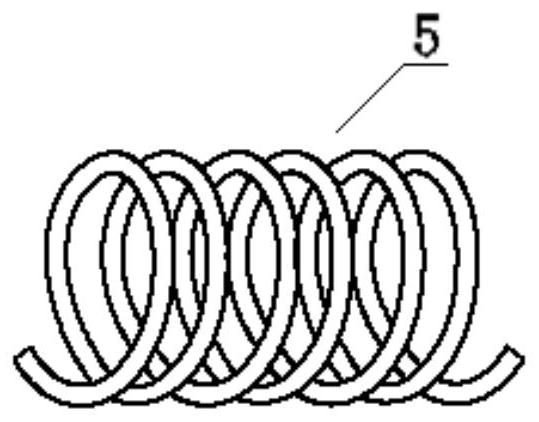

[0053] In the large-diameter tungsten rod annealing device of Example 1, the entrance angles of the inlet guide and the outlet guide are both 120°, the inner diameter of the induction coil is 35mm, and the length is 90mm.

[0054] The large-diameter tungsten rod annealing process in Example 1 includes: passing cooling circulating water from the cooling system to the large-diameter tungsten rod annealing device, the pressure of the cooling circulating water is controlled to 0.2Mpa, and then passing through the hydrogen gas pipe to the hydrogen protection box Hydrogen, the hydrogen flow rate is controlled at 16L / min, and the hydrogen ventilation time is controlled at 5min; start the motor, drive the feeding device and the discharging device, adjust the frequency of the frequency converte...

Embodiment 2

[0057] In embodiment 2, use the large-diameter tungsten rod annealing device of the present invention and annealing process to diameter be The rare earth doped tungsten alloy rods are annealed.

[0058] In the large-diameter tungsten rod annealing device of Example 2, the entrance angles of the inlet guide and the outlet guide are both 125°, the inner diameter of the induction coil is 40mm, and the length is 90mm.

[0059] The large-diameter tungsten rod annealing process in Example 2 includes: passing cooling circulating water from the cooling system to the large-diameter tungsten rod annealing device, the pressure of the cooling circulating water is controlled to 0.2Mpa, and then passing through the hydrogen gas pipe to the hydrogen protection box Hydrogen, the hydrogen flow rate is controlled at 20L / min, and the hydrogen ventilation time is controlled at 5min; start the motor, drive the feeding device and the discharging device, adjust the frequency of the frequency conver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com