Heat flow meter dynamic characteristic calibration device and method

A calibration device and technology of dynamic characteristics, applied in the field of sensor calibration, can solve the problems of high environmental requirements, low calibration accuracy, manual operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

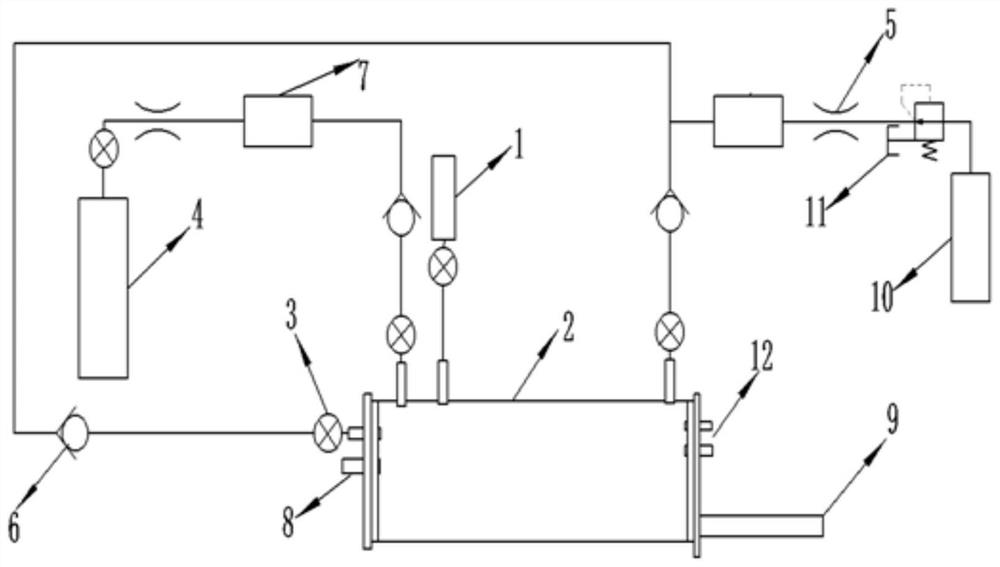

[0036] A dynamic characteristic calibration system of transient heat flow sensor based on pulse detonation engine gas jet flow. Such as figure 1 As shown, copper pipes with a diameter of 40-60mm and a length of 1200-1500mm are used as the detonation tube 2, engine fixing frame, hydrogen and oxygen tank 4, nitrogen tank 10, vacuum pump 1, spark plug 8, air valve, pneumatic channel, HFM Type heat flow sensor, data collector and notebook computer.

[0037] The hydrogen and oxygen tank 4 is filled with hydrogen and oxygen according to the ratio of 2:1, which is used as fuel for the pulse detonation engine. The gas tank 4 is connected with the flow-limiting throat, electromagnetic valve, anti-backfire valve, manual valve and combustion chamber in sequence. The function of the flow-limiting throat is to control the gas flow rate of the pipeline to less than 10m / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com