Method of manufacturing composite anode material and composite anode material applied to lithium secondary battery

A lithium secondary battery and negative electrode material technology, applied in secondary batteries, battery electrodes, lithium storage batteries, etc., can solve the problems of high price of silicon nanoparticles, achieve the effect of solving volume changes, reducing resistance, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

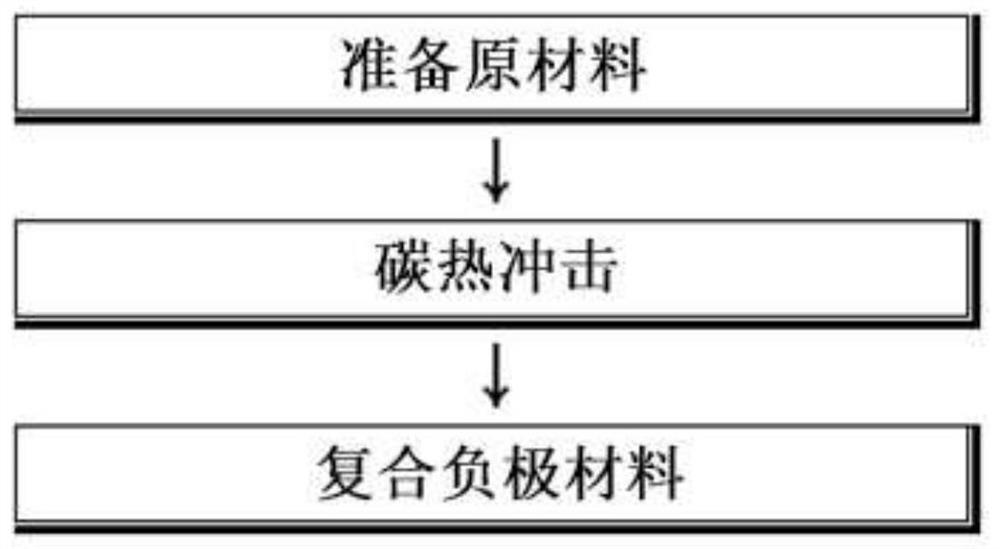

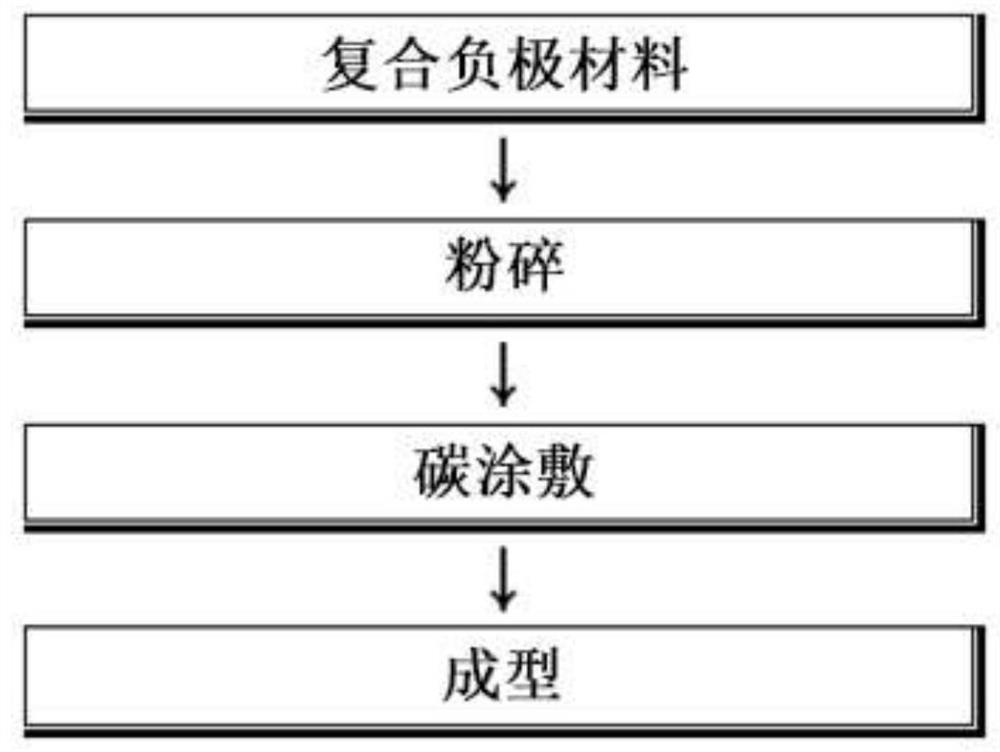

Method used

Image

Examples

Embodiment 1

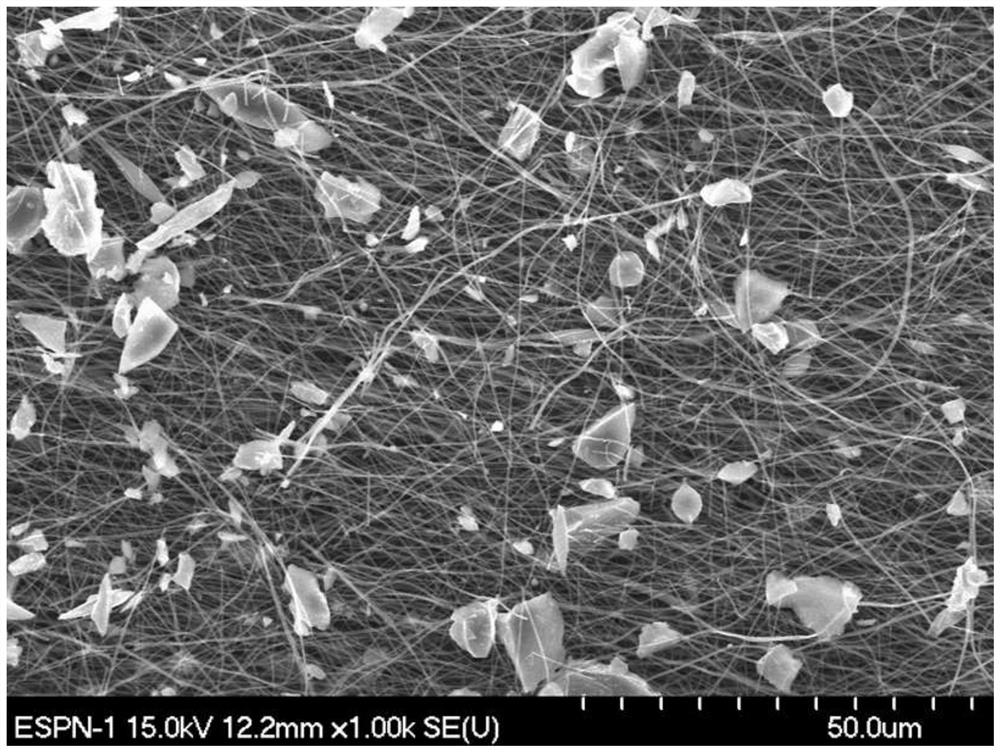

[0056] Composite anode materials were prepared using carbon fibers prepared by electrospinning and 325-mesh micro-silicon particles. The 325-mesh micro-silicon particles use commonly used products and are composed of particles smaller than 42 μm, so they have a size of micron units. Carbon thermal shock was applied to the carbon fiber dip-coated in ethanol with 5% concentration of microsilicon particles, and the carbon thermal shock condition was to apply a current of 53A under the voltage condition of 120V for 1 second.

[0057] image 3 This is a photograph of simply mixing carbon fiber and micro silicon particles before applying carbon thermal shock, Figure 4 It is a photograph of the state after carbon thermal shock was applied.

[0058] Before applying carbon thermal shock, a state where silicon particles having a size in units of micrometers and carbon fibers prepared by electrospinning were simply mixed could be confirmed.

[0059] However, after the carbon thermal ...

Embodiment 2

[0061] Composite anode materials were prepared by using expanded graphite flakes and 325-mesh micro-silicon particles. After dip-coating on phenolic resin dispersed with 6% micro-silicon particles, dry it in the atmosphere for 24 hours, then stabilize it to ensure that the residual carbon remains as a solid component in a nitrogen atmosphere at 350 ° C, and then check the expansion Carbon thermal shock is applied to the graphite sheet, and the carbon thermal shock condition is to apply a current of 95 A for 30 seconds at a voltage of 220 V. The silicon particles are brought into contact with the graphite flakes, while residual carbon remains as a solid component, so that the thermal energy of the rapidly heating graphite flakes can be sufficiently transferred to the silicon particles.

[0062] Figure 5 This is a photograph of a case where expanded graphite flakes and micro-silicon particles are simply mixed before carbon thermal shock is applied, Figure 6 is a photograph o...

Embodiment 3

[0072] Composite anode materials were prepared by using natural graphite and 325-mesh micro-silicon particles.

[0073] After mixing natural graphite and micro-silicon particles at a weight ratio of 8:2 and pressing and molding, carbon thermal shock was applied, and the carbon thermal shock condition was applied at a voltage of 150V and a current of 57A for 10 seconds.

[0074] Figure 9 It is a photo of the case where natural graphite and micro-silicon particles are mixed and pressed before applying carbon thermal shock, Figure 10 It is a photograph of the surface of natural graphite after carbon thermal shock is applied.

[0075] Not all of the microsilicon particles mixed with natural graphite were melted, but it was confirmed that some of the silicon particles were melted and impregnated in the form of particles on the surface of natural graphite by carbon thermal shock.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com