High-power formable multi-layer composite bus bar for space navigation

A multi-layer composite and bus bar technology, applied in the direction of fully enclosed busbar device, cooling busbar device, etc., can solve the problems of slow heat dissipation and large heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

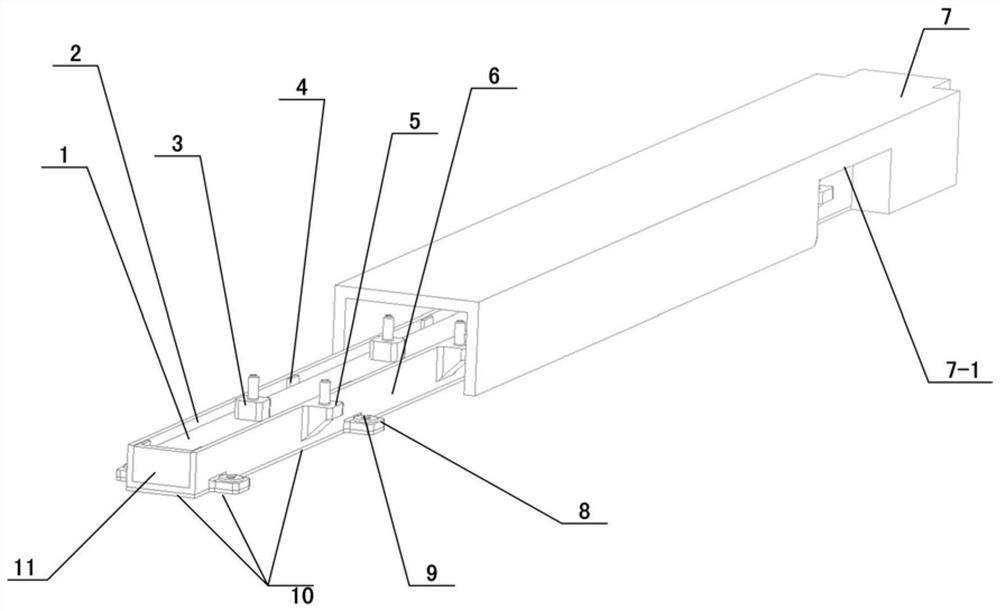

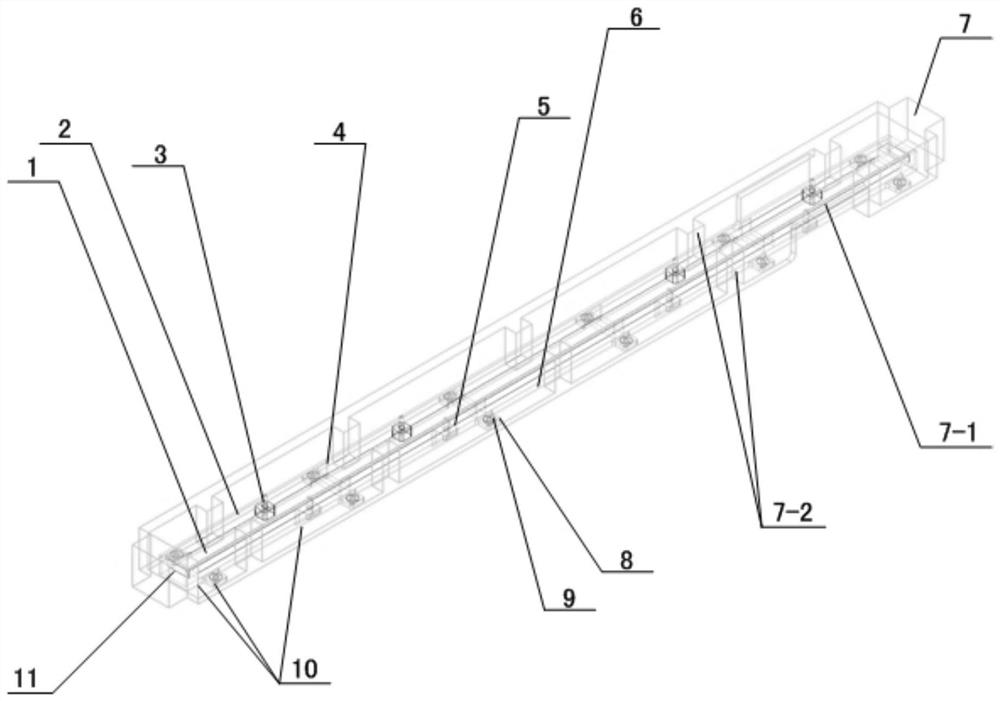

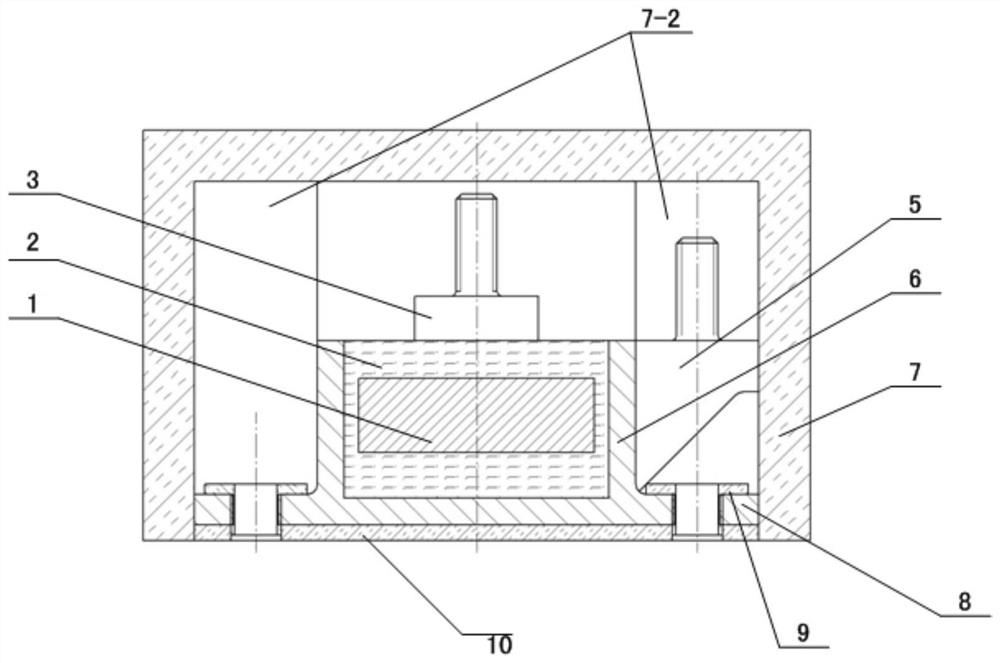

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0037] The present invention is a high-power formable multi-layer composite bus bar for aerospace, comprising a bus positive bus 1, a cavity insulating glue 2, a positive bus terminal 3, an insulating component 4 of the cavity, a negative bus terminal 5, and a negative bus terminal 5. Negative bus bar 6 , outer insulating cover 7 , bus negative bus bar mounting slot 8 , insulating mounting sleeve 9 , bus bar protective insulating plate 10 , and terminal insulating assembly 11 . The bus positive bus 1 is connected to the high-voltage end and is located in the middle, and the negative bus 6 is connected to the low-voltage end (that is, the DC zero-potential end), which is U-shaped and surrounds the positive bus 1 on three sides, so that the high-voltage end and the low-voltage end are energized to generate The electric field lines are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com