Method for recovering DMF from trichloroethane

A technology of trichloroethane and sucralose, applied in chemical instruments and methods, preparation of sugar derivatives, sugar derivatives, etc., can solve the problems of valuable solvent DMF waste, waste water, etc., to reduce production costs and reduce pollution , the effect of reducing the amount of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

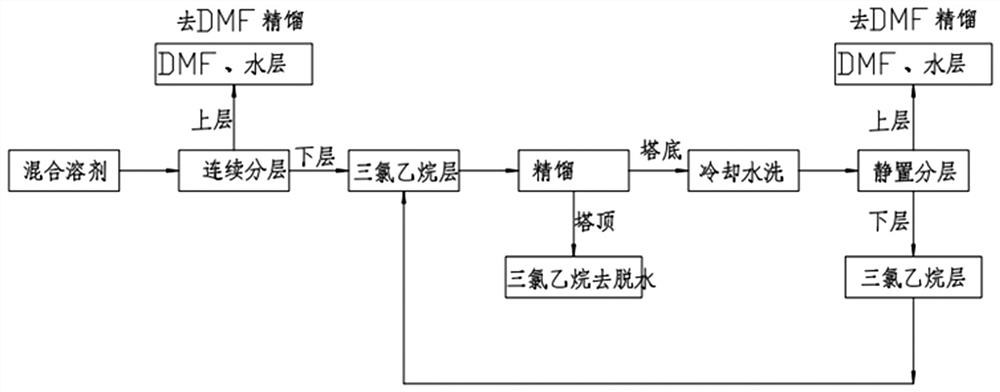

[0020] Such as figure 1 , figure 2 As shown, the trichloroethane, DMF, and water mixed solvents produced in the desolventization process after the neutralization of sucralose are pumped into the continuous layerer for layering, and the upper layer DMF and the water layer are removed from DMF and rectified to recover DMF. The lower trichloroethane heavy phase contains about 6% DMF due to the presence of impurities.

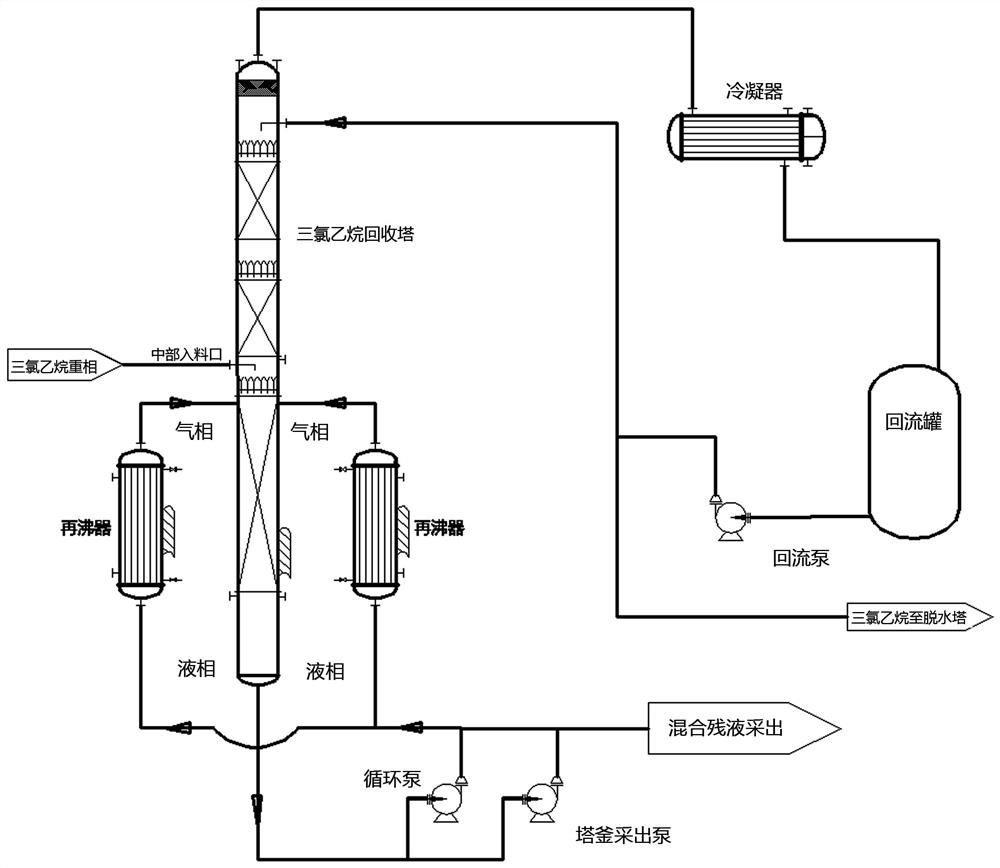

[0021] Then the trichloroethane heavy phase is pumped into the rectification tower from the middle inlet of the trichloroethane rectification tower, and the trichloroethane heavy phase material flowing to the bottom of the rectification tower is pumped into the bottom liquid of the reboiler through a circulating pump. Phase inlet, the trichloroethane gas phase after vaporization (temperature 60 degrees, pressure -0.086MPa) of the reboiler enters the middle of the rectification tower and the interior of the rectification tower from the top outlet of the reboiler ...

Embodiment 2

[0025] The mixed solvent of trichloroethane, DMF and water produced in the precipitation process after the neutralization of sucralose is pumped into the continuous layerer for layering. The ethane layer is removed from the trichloroethane for recovery. In the normal production process, the lower layer of trichloroethane contains about 6% DMF due to the presence of impurities.

[0026] Then the trichloroethane is continuously sent into the trichloroethane rectification tower with a pump, and the top of the tower adopts two-stage condensation and then enters the condensing reflux tank, part of which is extracted and partly refluxed, and the reflux controls the temperature at the top of the tower to not exceed 42°C. The output is trichloroethane with a purity of 98.5%, DMF≦1%, and a water content of about 1000-5000ppm.

[0027] Trichloroethane directly goes to the dehydration tower to remove moisture by vacuum distillation. When the moisture is ≦300ppm, it is directly extracted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com