Method for extracting and purifying broad-spectrum hemp oil from hemp

A technology of hemp oil and hemp, which is applied in the direction of fat oil/fat production, fat oil/fat refining, fat production, etc. It can solve the problems of low extraction rate, large loss of solvent recovery, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Harvest cannabis leaves and flowers, dry them at 80°C until the water content is 5%, and crush the materials to 20 mesh to obtain clean materials for use.

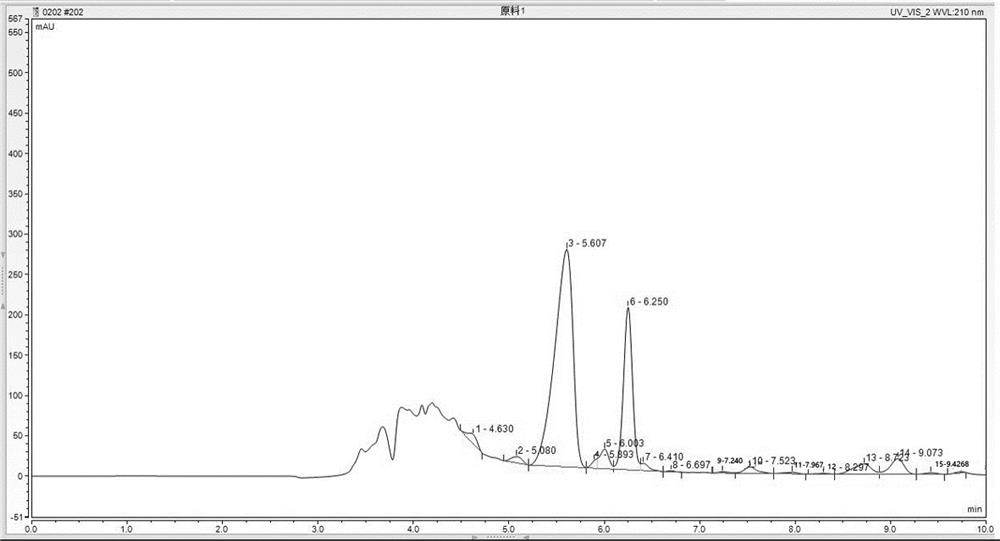

[0051] Weigh 60kg of cannabis powder, feed continuously at a feed rate of 15kg / h, use 8 times the ethanol solution of 60% concentration as the solvent, and feed ethanol solution continuously at 120L / h, the extraction temperature is 20°C, and the extraction time is 30min, the extraction is completed and the crude extract is collected, and the parameters for obtaining the relevant substances of high performance liquid chromatography are shown in figure 1 .

[0052] The obtained crude extract was concentrated in a vacuum low-temperature concentrator at a concentration temperature of 60°C to an extract, and the extract was further heated to 130°C for a decarboxylation reaction for 1 hour to obtain a decarboxylation solution.

[0053] The decarboxylation solution is subjected to short-range molecular distillation, and t...

Embodiment 2

[0058] The cannabis leaves and flowers are harvested, dried at 150°C to a moisture content of 3%, and the materials are crushed to 80 mesh to obtain clean materials for use.

[0059] Weigh 60kg of cannabis powder, feed continuously at a feed rate of 15kg / h, use 4 times the ethanol solution of 95% concentration as the solvent, and feed the ethanol solution continuously at 60L / h, the extraction temperature is 40°C, and the extraction time is 120min, the extraction is completed and the crude extract is collected, and the parameters for obtaining the relevant substances of high performance liquid chromatography are shown in figure 1 .

[0060] The obtained crude extract was concentrated in a vacuum low-temperature concentrator at a concentration temperature of 70°C to the extract, and the extract was further heated to 150°C for a decarboxylation reaction for 2 hours to obtain a decarboxylation solution.

[0061] The decarboxylation solution is subjected to short-range molecular d...

Embodiment 3

[0067] The cannabis leaves and flowers are harvested, dried at 100°C to a water content of 3%, and the materials are crushed to 50 mesh to obtain clean materials for use.

[0068] Weigh 60kg of cannabis powder, feed continuously at a feed rate of 15kg / h, use 20 times the ethanol solution of 65% concentration as the solvent, and feed the ethanol solution continuously at 1200L / h, the extraction temperature is 30°C, and the extraction time is 80min, the extraction is completed and the crude extract is collected, and the parameters for obtaining the relevant substances of high performance liquid chromatography are shown in figure 1 .

[0069] The obtained crude extract was concentrated by a vacuum low-temperature concentrator at a concentration temperature of 65°C to an extract, and the extract was further heated to 140°C for a decarboxylation reaction for 1.5 hours to obtain a decarboxylation solution.

[0070] The decarboxylation solution is subjected to short-range molecular d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com