Method for smelting titanium-silicon-aluminum intermediate alloy by reducing titanium-containing blast furnace slag with aluminum under atmosphere protection

A technology of aluminum master alloy and master alloy, which is applied in the field of metallurgy, can solve problems such as no practical operation guidance significance, and achieve the effects of less impurities, less waste, and high titanium content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

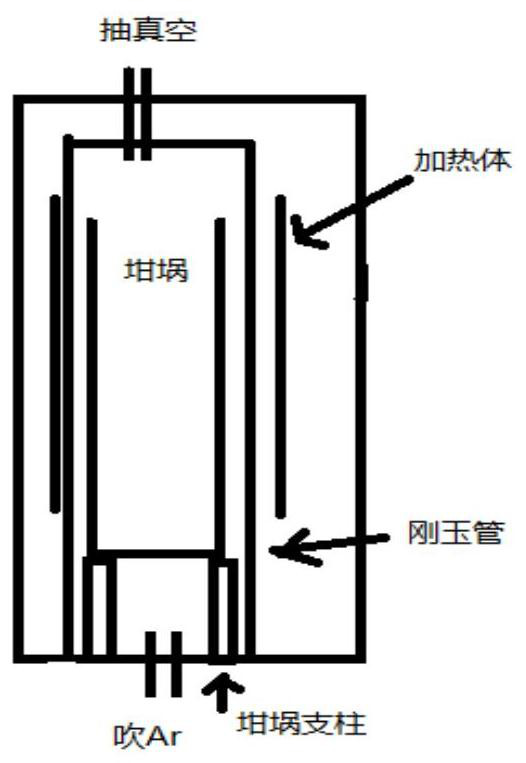

[0038] In this embodiment, the method of titanium-containing blast furnace slag vacuum decompression protection aluminothermic reduction smelting titanium-silicon-aluminum alloy includes the following steps:

[0039] A. Crush the solid titanium-containing blast furnace slag, aluminum powder, lime, and fluorite to a particle size of 0.5mm; mix 100g of solid titanium-containing blast furnace slag, 30-50g of aluminum powder, 20-28g of lime and 0-10g of fluorite Until the mixing degree is ≥98.5%, after pelletizing and drying, the pellet material is obtained; the pellet material is put into figure 1 In the vacuum reduction reaction device shown, the aluminum reduction metallurgical reaction is protected under a vacuum decompression atmosphere for 0.5h at a temperature of 1550°C and a vacuum degree of 100Pa;

[0040] B. After the reaction is completed, the reaction product is isolated from air and cooled to room temperature, and the slag and alloy are mechanically separated to obtai...

Embodiment 5

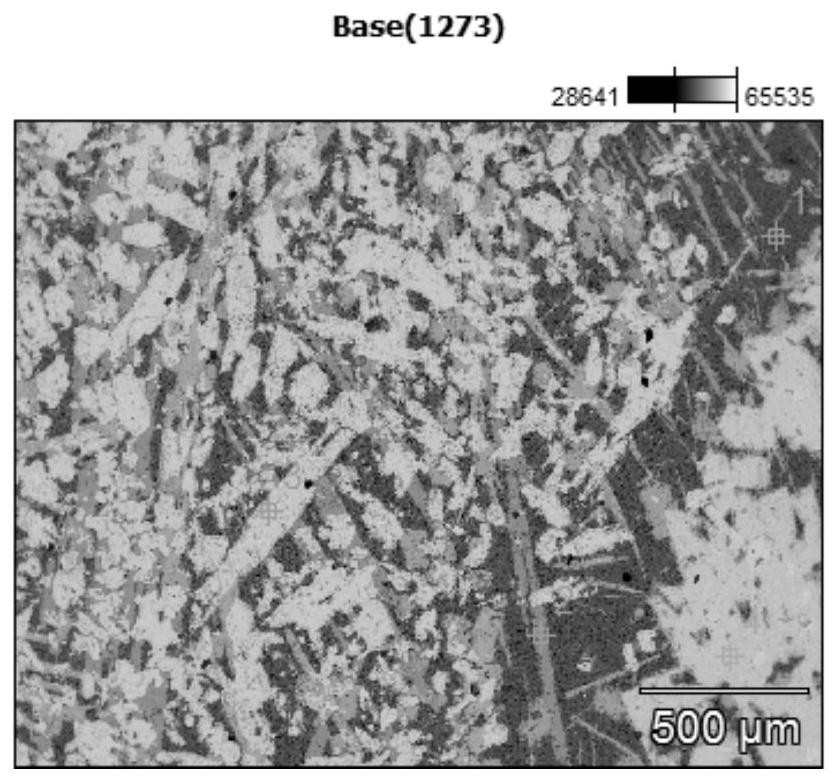

[0044] Example 5 Reaction alloy product and slag, alloy separation effect diagram see for details figure 2 . Embodiment 5 reaction alloy product scanning electron microscope picture sees for details image 3 . Depend on figure 2 It can be seen that the alloy product of the present invention is easy to separate from slag, the automatic separation effect of slag and alloy is good, and the boundary between slag and alloy is obvious. Depend on image 3 It can be seen that the alloy structure of the present invention is uniform in shape and clear in structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com