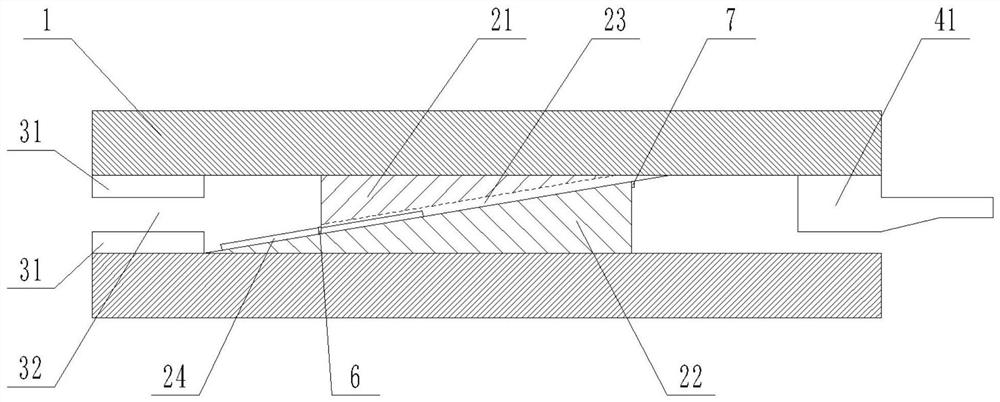

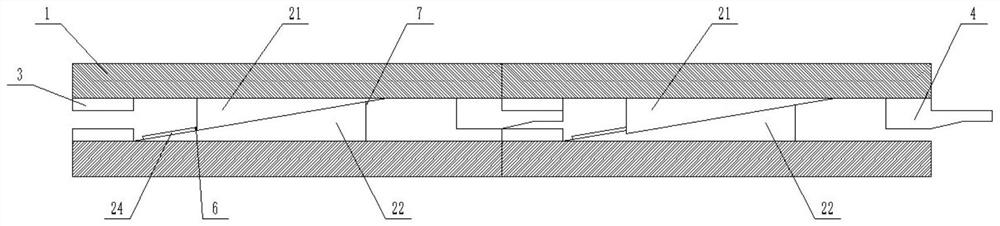

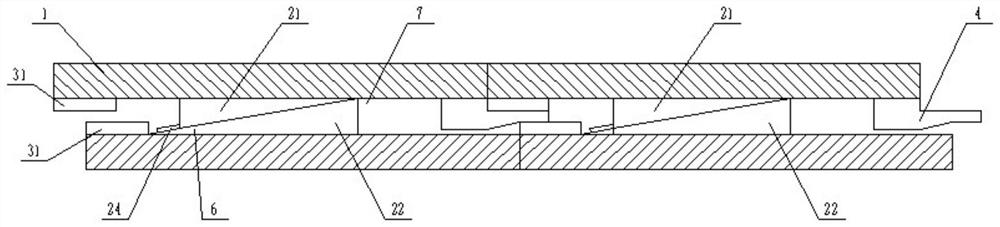

Energy-saving panels for building walls

A technology for building walls and energy-saving panels, applied in buildings, building components, building structures, etc., can solve the problems of reducing noise reduction and heat preservation, poor heat preservation effect, and poor sound insulation effect, and achieves improved seismic performance and low closed cell rate , the effect of increasing the porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The lightweight sound-absorbing board is prepared by the following method: kraft paper is soaked in modified phenolic resin, then taken out, dried and solidified, and laminated to form an adhesive paper, which is placed in a mold, and then the mass ratio is 40 : 7:2:15:10:3:12 modified phenolic resin, Momentive L6950, inorganic ultrafine particles (slag powder, fly ash, desulfurization with a mass ratio of 20:10:10:5:12:40 Made of gypsum, metakaolin, coal gangue and polydimethylsiloxane, the particle size D50 of the material is below 8μm, the particle size D95 is below 20μm, and the specific surface area is 850-900m 2 / kg), curing agent (HZSM-5 solid acid and methanesulfonic acid with a mass ratio of 2:12), polyethylene glycol, liquid paraffin and cyclopentane are put into the container together, and after 10-20 minutes of normal temperature reaction, the temperature rises to 70-80°C and keep warm for 1-2h; the modified phenolic resin is prepared by the following method...

Embodiment 2

[0024] The lightweight sound-absorbing board is prepared by the following method: kraft paper is soaked in modified phenolic resin, then taken out, dried and solidified, and laminated to form an adhesive paper, which is placed in a mold, and then the mass ratio is 55 : 10: 5: 22: 15: 5: 15 Modified phenolic resin, Momentive L6950, inorganic ultrafine particles (slag powder, fly ash, desulfurized gypsum with a mass ratio of 30: 22: 15: 8: 18: 60 , metakaolin, coal gangue and polydimethylsiloxane, the material particle size D50 is below 8μm, the particle size D95 is below 20μm, and the specific surface area is 850-900m 2 / kg), curing agent (HZSM-5 solid acid and methanesulfonic acid with a mass ratio of 6:15), polyethylene glycol, liquid paraffin and n-pentane are put into the container together, and after normal temperature reaction for 10-20min, the temperature is raised to 70-80°C, keep warm for 1-2h; the modified phenolic resin is prepared by the following method: at a tempe...

Embodiment 3

[0026]The light-weight sound-absorbing board is prepared by the following method: kraft paper is soaked in modified phenolic resin, then taken out, dried and solidified, and laminated to form an adhesive paper, which is placed in a mold, and then the mass ratio is 50 : 9:4:20:15:4:12 modified phenolic resin, Momentive L6950, inorganic ultrafine particles (slag powder, fly ash, desulfurization with a mass ratio of 22:12:12:6:15:45 Made of gypsum, metakaolin, coal gangue and polydimethylsiloxane, the particle size D50 of the material is below 8μm, the particle size D95 is below 20μm, and the specific surface area is 850-900m 2 / kg), curing agent (HZSM-5 solid acid and methanesulfonic acid with a mass ratio of 3:14), polyethylene glycol, liquid paraffin and cyclopentane are put into the container together, and after reacting at room temperature for 10-20min, the temperature is raised to 70-80°C and keep warm for 1-2h; the modified phenolic resin is prepared by the following metho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com