Method for measuring phosphorus content in high-carbon ferrochrome

A technology with high carbon ferrochromium and phosphorus content, applied in the measurement of color/spectral characteristics, etc., can solve problems such as high risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0018] 1. Experimental method

[0019] 1.1 Main instruments and reagents

[0020] 1.1.1 High temperature muffle furnace

[0021] 1.12 millionth balance

[0022] 1.1.3 Nitric acid (the ratio of nitric acid to water is 1:5)

[0023] 1.1.4 Bismuth nitrate: Weigh 5g of bismuth nitrate and dissolve it in 1L of boiling 1mol / L nitric acid solution.

[0024] 1.1.5 Ammonium molybdate-potassium sodium tartrate solution: 3% ammonium molybdate solution and 5% potassium sodium tartrate solution are mixed in equal volumes, and mixed immediately after use.

[0025] 1.1.6 Ascorbic acid-ethanol solution: Weigh 2g of ascorbic acid and dissolve it in 100ml of ethanol solution (the ratio of ascorbic acid to ethanol is 1:9), and prepare it immediately after use.

[0026] 1.2. Experimental method

[0027] Weigh 0.2000g of the sample into a paper tube containing 2g of boric acid + anhydrous sodium carbonate mixed flux, stir well, wrap it well, put it into a graphite crucible, and melt it in a m...

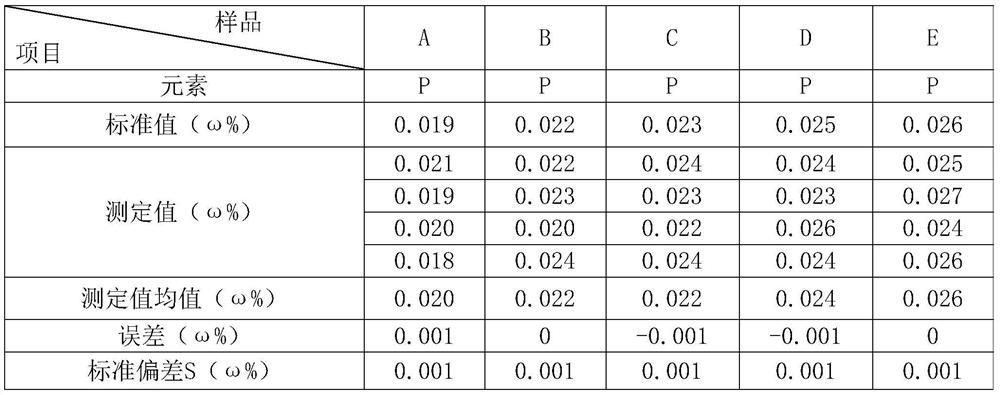

Embodiment 1

[0036] Weigh 0.2000g of high-carbon ferrochromium sample A into a paper tube containing 2g of boric acid + anhydrous sodium carbonate mixed flux, stir well, wrap it well, put it into a graphite crucible, and melt it in a muffle furnace at 900-950°C for 10 minute. Take it out and cool it, put it into a 250ml beaker filled with 70ml (the ratio of nitric acid and water is 1:5) nitric acid, heat and dissolve on the electric heating plate, after the sample is dissolved, filter it with a absorbent cotton filter into a 250ml volumetric flask, Dilute to volume with water and shake well.

[0037] Draw 25ml of the mother liquor into a 50ml volumetric flask, add 5ml of bismuth nitrate solution, 10ml of ammonium molybdate-potassium sodium tartrate solution, 10ml of ascorbic acid-ethanol solution, until the color develops, dilute with water to the scale and shake well, on the spectrophotometer, 680nm 3 cm cuvette, with water as a reference, measure the absorbance. Use the standard sample...

Embodiment 2

[0039] Weigh 0.2001g of high-carbon ferrochromium sample B into a paper tube containing 2g of boric acid + anhydrous sodium carbonate mixed flux, stir well, wrap it well, put it into a graphite crucible, and melt it in a muffle furnace at 900-950°C for 10 minute. Take it out and cool it, put it into a 250ml beaker filled with 70ml (the ratio of nitric acid and water is 1:5) nitric acid, heat and dissolve on the electric heating plate, after the sample is dissolved, filter it with a absorbent cotton filter into a 250ml volumetric flask, Dilute to volume with water and shake well.

[0040] Draw 25ml of the mother liquor into a 50ml volumetric flask, add 5ml of bismuth nitrate solution, 10ml of ammonium molybdate-potassium sodium tartrate solution, 10ml of ascorbic acid-ethanol solution, until the color develops, dilute with water to the scale and shake well, on the spectrophotometer, 680nm 3 cm cuvette, with water as a reference, measure the absorbance. Use the standard sample...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com