Low-temperature foaming process for batch preparation of thin-layer carbon-loaded nano ZnO wave-absorbing material

A wave-absorbing material and thin-layer technology, applied in aerospace and electromagnetic absorption fields, can solve problems such as weakening electromagnetic impedance matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

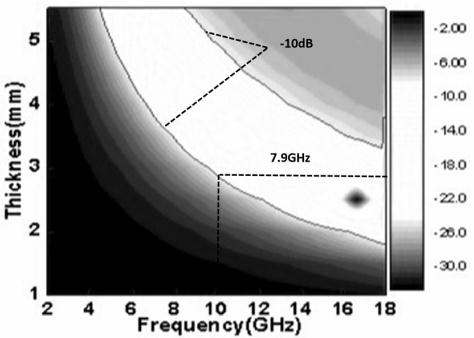

Embodiment 1

[0025] Take 1 g of glucose and 2 g of zinc nitrate and dissolve them in 10 ml of deionized water to form a uniformly mixed solution. The prepared solution was moved to a blast drying oven, dried at 120° C. for 12 hours, and foamed and polymerized to obtain a porous and light expanded precursor. The prepared precursor was transferred to a tube furnace, and the temperature was raised to 700°C at 5°C / min under a protective atmosphere of nitrogen, and kept at 700°C for 2 hours. After annealing, a thin layer of carbon-supported nano-ZnO composite material was obtained. Then heat the composite material and the wave-transmitting material according to the ratio of material: paraffin = 1:10 until they are evenly mixed, press them into an annular tube with an outer diameter of 7.0 mm and an inner diameter of 3.0 mm, and test its wave-absorbing performance.

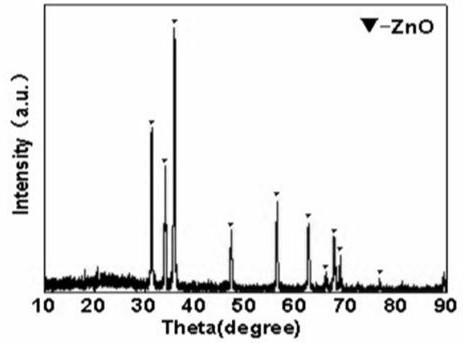

[0026] figure 1 It is a diagram of the expanded precursor foamed and polymerized under the low-temperature foaming method in Exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com