Whey protein isolate nanofiber/carbon nanotube composite material and preparation method thereof

A whey protein isolate and carbon nanotube technology, which is applied in the field of whey protein isolate nanofiber/carbon nanotube composite materials and their preparation, and can solve the problems of in vivo research or in vitro research that have not been reported.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

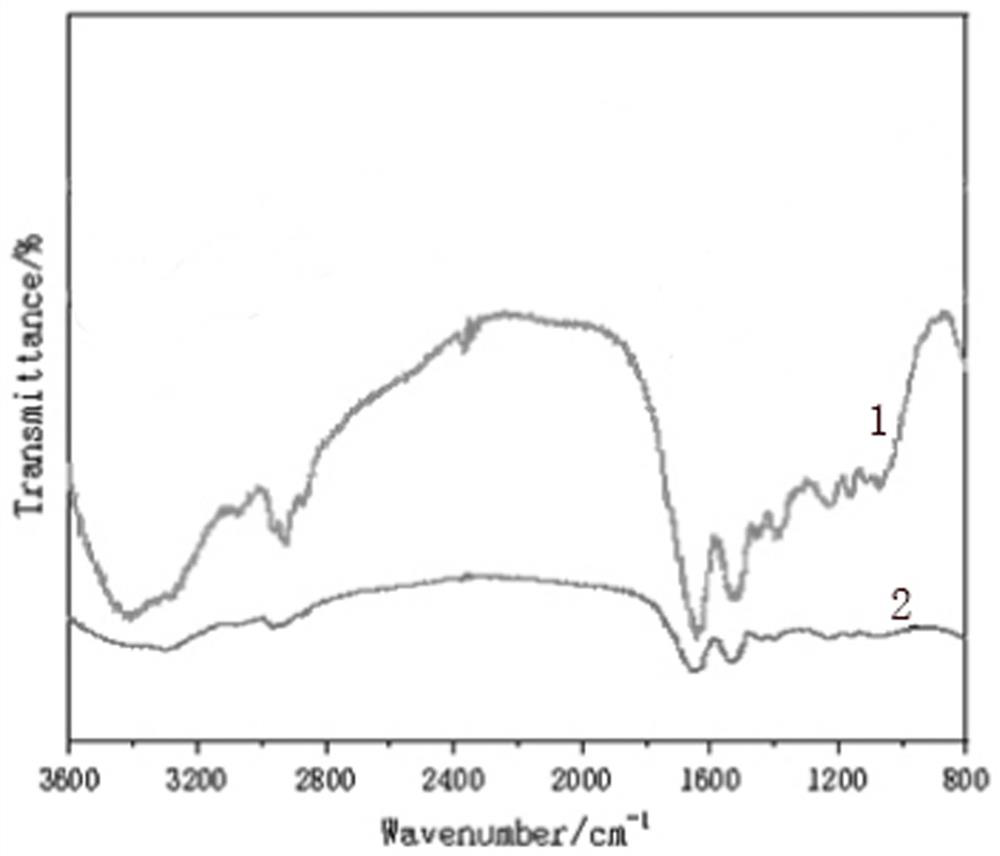

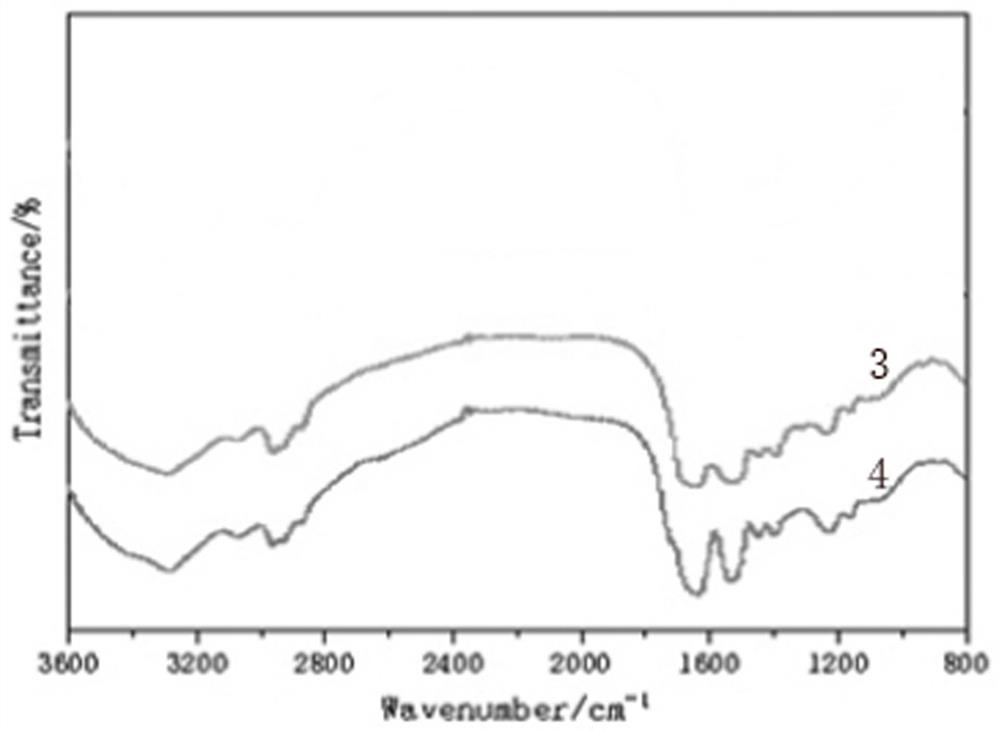

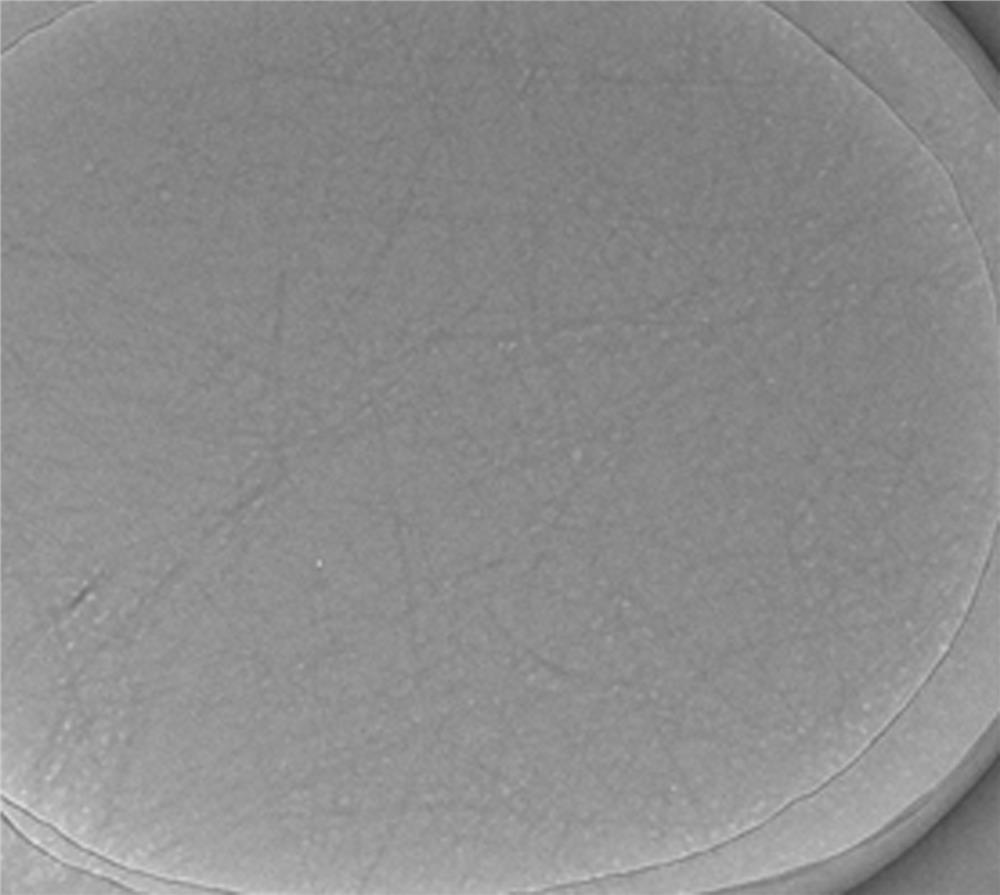

Method used

Image

Examples

Embodiment 1

[0030] A preparation method of whey protein isolate nanofiber / carbon nanotube composite material, comprising the following steps:

[0031] (1) Preparation of whey protein isolate nanofiber solution:

[0032] Stir and dissolve whey protein isolate with a protein content of 97.80% and no lecithin in deionized water to prepare a stock solution with a mass concentration of 6 wt%;

[0033] Add 1M hydrochloric acid solution to adjust the pH value of the stock solution to 4.75;

[0034] Then the stock solution with a pH value of 4.75 was put into a centrifuge at 10000rpm and centrifuged for 60min;

[0035] Filter the supernatant with a supply syringe filter with a pore size of 0.45 μm;

[0036] The pH value of the filtered supernatant was adjusted to 2 with 6M hydrochloric acid solution;

[0037] Determine the protein concentration of the supernatant using a UV spectrophotometer and a calibration curve of known whey protein isolate concentrations at a wavelength of 278 nm;

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com