Nano solid defoamer for foam drainage gas recovery of gas well, and preparation method thereof

A technology of solid defoaming agent and foam drainage, applied in separation methods, foam dispersion/prevention, chemical instruments and methods, etc., can solve problems such as poor defoaming effect, high cost, and weak stability, and achieve defoaming and The effect of strong antifoaming ability, wide source of raw materials and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] This embodiment provides a nano-silica particle modified with polydimethylsiloxane.

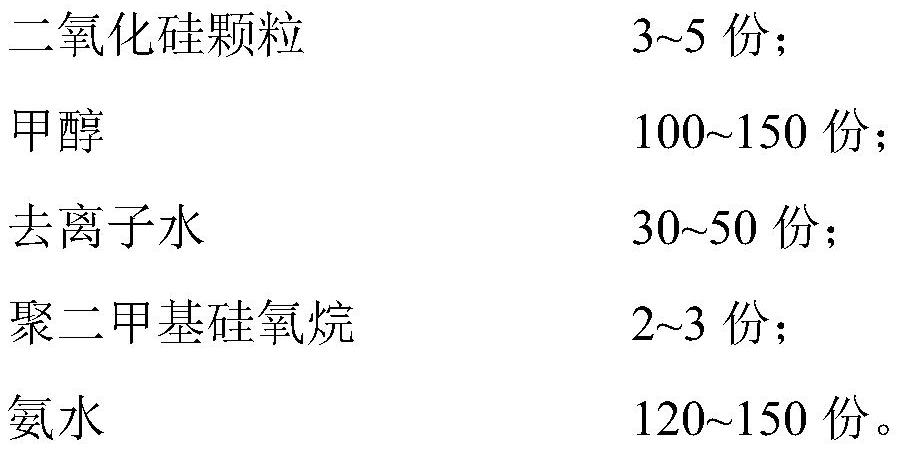

[0043] The raw material composition of the polydimethylsiloxane-modified nano silicon dioxide particles comprises:

[0044] 3g of silicon dioxide particles with a particle size of 12nm, 120mL of ammonia water with a concentration of 24wt%, 2mL of polydimethylsiloxane, 100mL of methanol and 30mL of deionized water; wherein, silicon dioxide particles, ammonia water, Both polydimethylsiloxane and methanol are analytically pure, and the resistivity of deionized water is 18MΩ·cm;

[0045]Its preparation method includes: weighing the raw materials according to the above ratio, adding silicon dioxide particles, methanol, polydimethylsiloxane and deionized water into a three-necked bottle in sequence, mixing evenly, stirring and heating at a speed of 600r / min to 60°C, react for 4 hours to obtain a mixed solution; add ammonia water to the mixed solution, continue to stir at a speed of 600r / min...

Embodiment 2

[0047] This embodiment provides a nano-solid defoamer for gas well foam drainage and gas recovery.

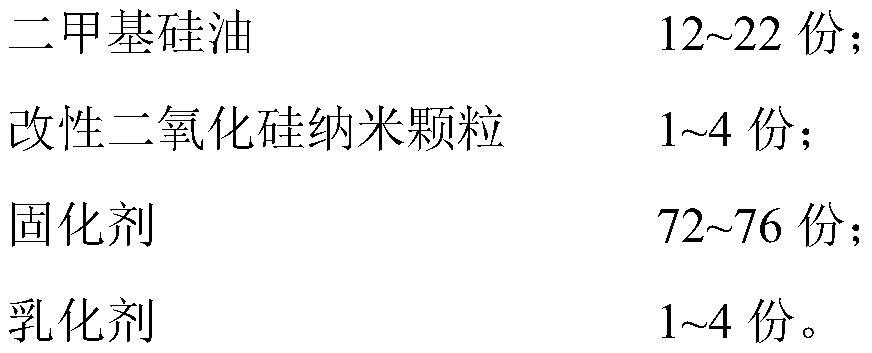

[0048] The raw material composition of the nano solid defoamer used for gas well foam drainage and gas recovery includes:

[0049] 1.2 g of polydimethylsiloxane-modified nano-silica particles prepared in Example 1, 21 g of simethicone oil, 2 g of emulsifier S-185 and 74 g of curing agent sucrose.

[0050] The preparation of the nano-solid defoamer for gas well foam drainage and gas recovery comprises the following steps:

[0051] Weigh the raw materials according to the above ratio, mix simethicone and polydimethylsiloxane-modified nano-silica particles evenly, heat to 240°C, stir the mixture for 4 hours at a speed of 4000r / min, and cool to 20°C to obtain the main body of the defoamer;

[0052] Heat the solidifying agent sucrose to 190°C to melt, add the main body of the defoamer and the emulsifier S-185, stir at a constant temperature of 600r / min for 1.5h, mix well, pour int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com