Graphene/aluminum oxide/titanium dioxide heterojunction material, preparation method and application thereof

A technology of titanium dioxide and graphene, applied in chemical instruments and methods, physical/chemical process catalysts, photosensitive equipment, etc., can solve the complex and difficult control methods of synthesizing functional material morphology and performance regulation, graphene agglomeration and other problems , to achieve the effect of controllable photoelectric characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

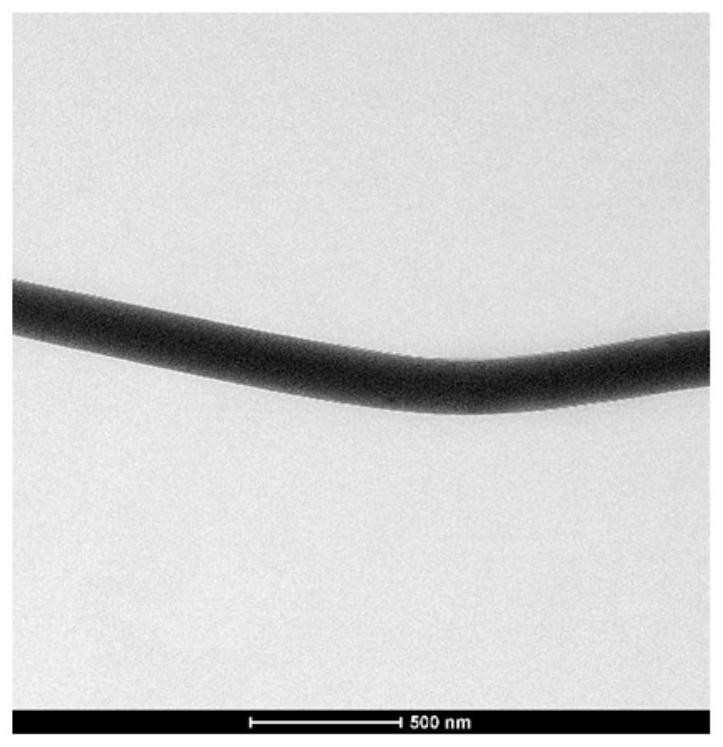

Image

Examples

Embodiment 1

[0027] a. Electrospinning combined with hydrothermal process was used to hydrothermally mix alumina / titania nanofibers with different contents of graphene oxide to prepare graphene / alumina / titania heterojunction composites.

[0028] First, prepare the electrospinning solution. Mix 0.6g of PVP with 4.5mL of absolute ethanol, stir magnetically at room temperature for 24 hours to obtain a uniform and transparent solution, add 5mL of acetone, 1g of aluminum acetylacetonate, 3mL of acetic acid and 1.4011mL of isopropyl titanate into the above solution, and stir at room temperature Dissolve it completely to obtain a uniform and transparent spinning solution. The resulting PVP / aluminum acetylacetonate / isopropyl titanate fibers were collected under the conditions of a voltage of 17.5kV, a distance between the metal needle and the metal mesh of 12.5cm, a flow rate of 0.5mL / h, and a spinning humidity of 50% or less. The fibers were calcined in a muffle furnace at 600°C for 290min with ...

Embodiment 2

[0037] a. Electrospinning combined with hydrothermal process was used to hydrothermally mix alumina / titania nanofibers with 10 wt.% graphene oxide to prepare graphene / alumina / titania heterojunction composites.

[0038] First, prepare the electrospinning solution. Mix 0.6g of PVP with 4.5mL of absolute ethanol, stir magnetically at room temperature for 24 hours to obtain a uniform and transparent solution, add 5mL of acetone, aluminum acetylacetonate, 3mL of acetic acid and 2.5mL of isopropyl titanate to the above solution in sequence, and stir at room temperature to make It dissolves completely to obtain a uniform and transparent spinning solution. Wherein the quality of adding aluminum acetylacetonate is respectively 0.4625g and 1.0407g. The resulting PVP / aluminum acetylacetonate / isopropyl titanate fibers were collected under the conditions of a voltage of 17.5kV, a distance between the metal needle and the metal mesh of 12.5cm, a flow rate of 0.5mL / h, and a spinning humidit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impedance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap