Three-dimensional graphene composite material loaded with single-layer flower-shaped MXene nanosheets, preparation method and application thereof

A composite material and graphene technology, applied in the direction of graphene, nanocarbon, nanotechnology, etc., can solve problems such as hindering application, inability to disperse, and easy agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

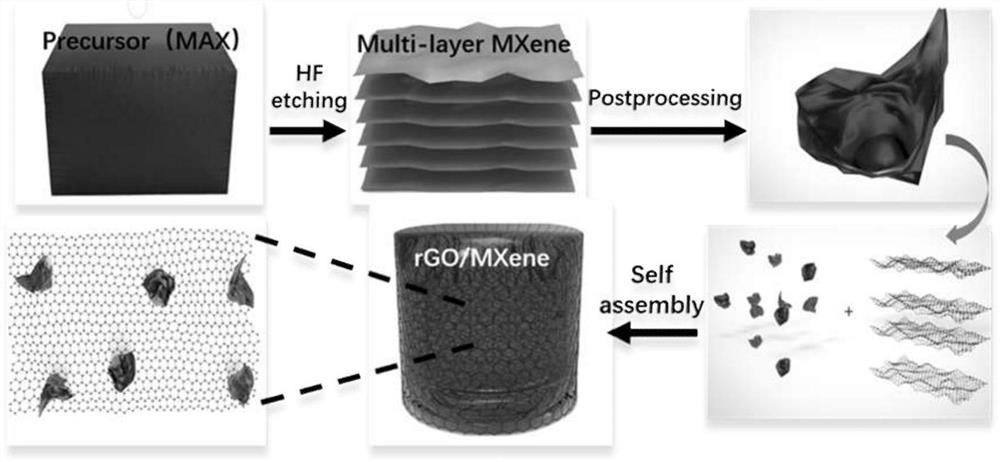

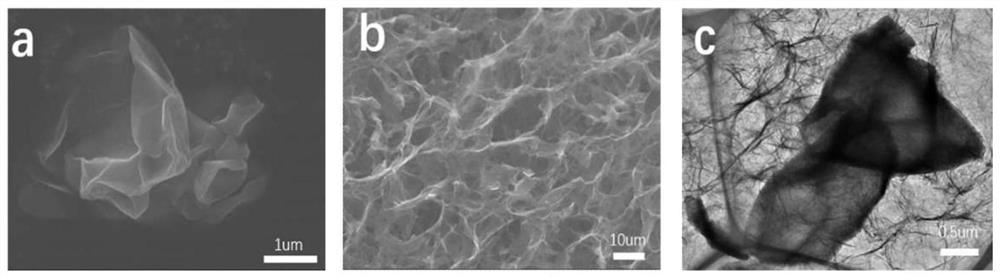

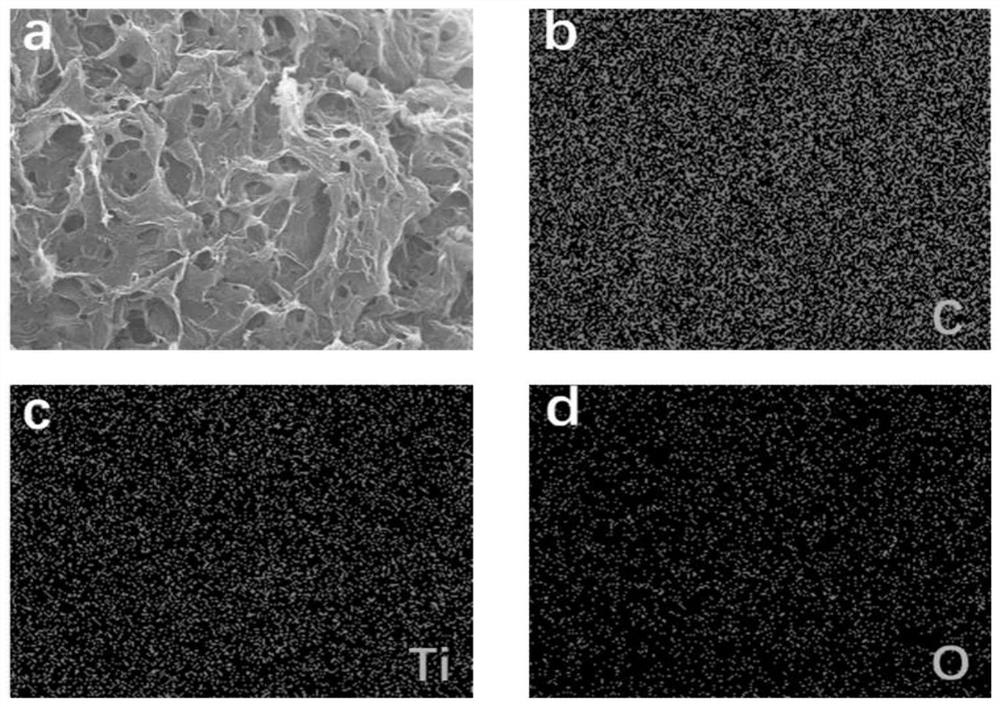

[0027] Load Ti 3 C 2 The three-dimensional graphene lithium-sulfur battery electrode material of nanosheet, it comprises the steps:

[0028] 1) Add 2g of Ti to the liner of 250mL reactor 3 AlC 2 (MAX), then add 20mL 40% HF solution and stir for 24h;

[0029] 2) The product of step 1) was centrifuged and washed to neutrality, then dispersed in 20 mL of 45% TMAOH solution and stirred for 24 h, then sonicated for 2 h under the protection of high-purity argon;

[0030] 3) The product of step 2) was washed with water, separated by centrifugation (2500rpm, 30min), and the separated product was treated with liquid nitrogen and directly transferred to a lyophilizer, and lyophilized at -40°C for 72h;

[0031] 4) The product of step 3) is spray-dried to obtain a single-layer flower-like Ti 3 C 2 (MXene) nanosheets;

[0032] 5) Add 2 mL of 1 mg mL graphene oxide dispersion into a 10 mL sample bottle, and stir ultrasonically for 10 min;

[0033] 6) Ti in step 4) 3 C 2 The nanosh...

Embodiment 2

[0046] Load Ti 2 The three-dimensional graphene lithium-sulfur battery electrode material of C nanosheet, it comprises the following steps:

[0047] 1) Add 2g of Ti to the liner of 250mL reactor 2 AlC(MAX), then add 20mL 40% HF solution and stir for 24h;

[0048] 2) The product of step 1) was centrifuged and washed to neutrality, then dispersed in 20 mL of 45% TMAOH solution and stirred for 24 h, then sonicated for 2 h under the protection of high-purity argon;

[0049] 3) The product of step 2) was washed with water, separated by centrifugation (2500rpm, 30min), and the separated product was treated with liquid nitrogen and directly transferred to a freeze dryer, and freeze-dried at -40°C for 72h;

[0050] 4) The product of step 3) is spray-dried to obtain a single-layer flower-like Ti 2 C(MXene) nanosheets;

[0051] 5) Add 2 mL of 1 mg mL graphene oxide dispersion into a 10 mL sample bottle, and stir ultrasonically for 10 min;

[0052] 6) Ti in step 4) 2 C nanosheets w...

Embodiment 3

[0060] Load Hf 3 C 2 The three-dimensional graphene lithium-sulfur battery electrode material of nanosheet, it comprises the steps:

[0061] 1) Add 2g of Hf into the 250mL reactor liner 3 AlC 2 (MAX), then add 20mL 40% HF solution and stir for 24h;

[0062] 2) The product of step 1) was centrifuged and washed to neutrality, then dispersed in 20 mL of 45% TMAOH solution and stirred for 24 h, then sonicated for 2 h under the protection of high-purity argon;

[0063] 3) The product of step 2) was washed with water, separated by centrifugation (2500rpm, 30min), and the separated product was treated with liquid nitrogen and directly transferred to a freeze dryer, and freeze-dried at -40°C for 72h;

[0064] 4) The product of step 3) is spray-dried to obtain a single-layer flower-like Hf 3 C 2 (MXene) nanosheets;

[0065] 5) Add 2 mL of 1 mg mL graphene oxide dispersion into a 10 mL sample bottle, and stir ultrasonically for 10 min;

[0066] 6) Hf in step 4) 3 C 2 The nanos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com