High-temperature-resistant ceramizable cement-based material and preparation method thereof

A cement-based material, ceramic technology, applied in the direction of cement production, etc., can solve the problems of decreased mechanical properties and durability, low fire resistance temperature, and inability to realize multiple fire protection functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

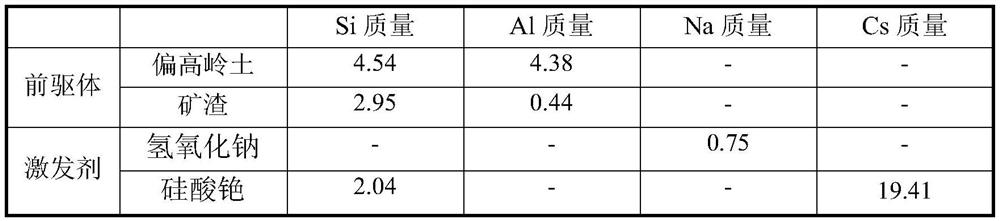

[0034]The target ceramic composition of this embodiment is designed so that the molar ratio of natrolite and cesium garnet is 1:9, and the molar ratio of the chemical elements of the precursor and the activator is calculated accordingly: Na / Al=2:11, Cs / Al =9:11, Si / Al=21 / 11, and the ratio of raw materials is selected according to the chemical composition of raw materials to meet the ratio of chemical elements. The specific ratio is as follows:

[0035] The precursor composed of metakaolin and slag and the activator composed of cesium silicate and sodium hydroxide with a weight of 60 kilograms, the chemical element molar ratio formed by the two together complies with the above chemical element ratio. In this embodiment, the specifically selected precursors are 18 kg of metakaolin, 14.3 kg of slag, 1.3 kg of sodium hydroxide and 26.4 kg of cesium silicate as activators. The mass (in kilograms) of the specific elements Na, Si, Al and Cs in the precursor and the activator analyzed...

Embodiment 2

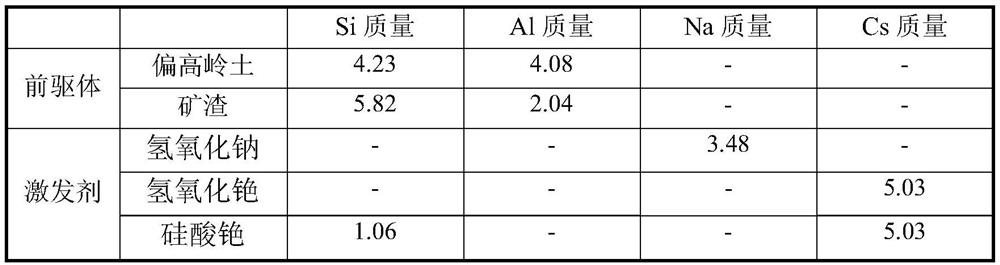

[0046] The target ceramic composition of this embodiment is designed so that the molar ratio of natrolite and cesium garnet is 1:1, and the molar ratio of the chemical elements of the precursor and the activator is calculated accordingly: Na / Al=2:3, Cs / Al =1:3, Si / Al=5:3, and the ratio of raw materials is selected according to the chemical composition of raw materials to meet the ratio of chemical elements. The specific ratio is as follows:

[0047] 68 kilograms of weight are composed of metakaolin, slag precursor and cesium hydroxide, cesium silicate, sodium hydroxide, and the molar ratio of chemical elements formed by the two meets the above-mentioned chemical element ratio; in the present embodiment , the specifically selected precursors are 16.78 kg of metakaolin, 32.66 kg of slag, 6.05 kg of sodium hydroxide, 5.67 kg of cesium hydroxide, and 6.84 kg of cesium silicate as activators. The mass (in kilograms) of the specific elements Na, Si, Al and Cs in the precursor and th...

Embodiment 3

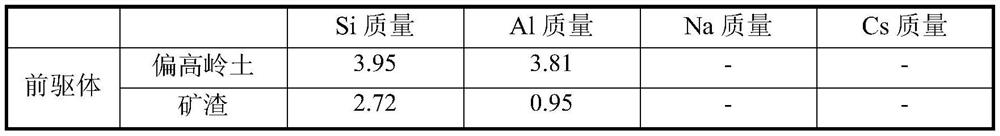

[0058] The target ceramic composition of this embodiment is designed so that the molar ratio of natrolite and cesium garnet is 4:1, and the molar ratio of the chemical elements of the precursor and the activator is calculated accordingly: Na / Al=8:9, Cs / Al =1:9, Si / Al=14:9, and select the ratio of raw materials according to the chemical composition of raw materials to meet the ratio of chemical elements, the specific ratio is as follows:

[0059] A precursor composed of metakaolin, slag, and fly ash and an activator composed of cesium hydroxide, cesium silicate, and sodium hydroxide with a weight of 75 kilograms. The chemical element molar ratio formed by the two meets the above chemical element ratio; In this embodiment, the precursors specifically selected are 15.68 kg of metakaolin, 15.25 kg of slag, 26.92 kg of fly ash, 11.3 kg of sodium hydroxide as activator, 2.65 kg of cesium hydroxide, 3.2 kg of silicon cesium acid. The mass (in kilograms) of the specific elements Na, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com