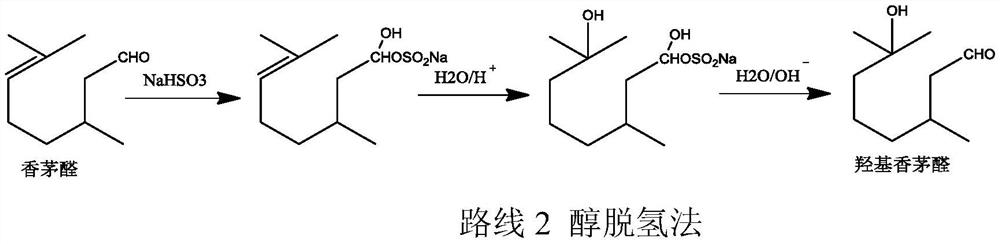

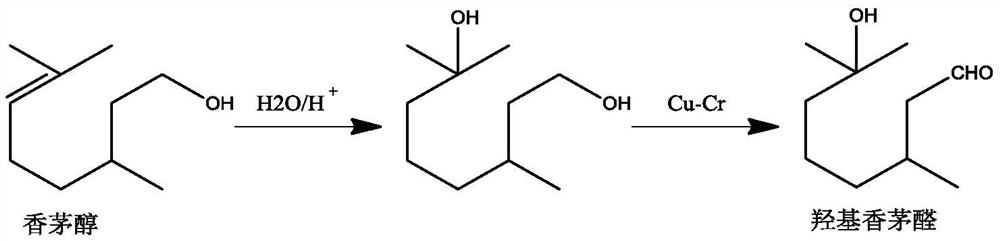

Method for preparing hydroxycitronellal through hydration reaction of citronellal

A technology for the hydration of hydroxycitronellal and malral, which is applied to the preparation of carbon-based compounds, the preparation of organic compounds, chemical instruments and methods, etc., to achieve the effects of simplified process flow, high selectivity, and reduced costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Pd / ZSM preparation:

[0065] 1) Preparation of Pd nano-sol

[0066] a) Take 10g polyvinylpyrrolidone, 5g Na 2 PdCl 4 Prepare a solution with 250g of water, and stir thoroughly at 10°C for 10h;

[0067] b) Take 3.86g NaBH 4 Add to the solution of a), fully stir at 10°C for 8h, then let it stand for 15h, and filter to obtain the nano-sol of metal Pd;

[0068] 2) Pd@SiO 2 preparation of

[0069] a1) Add 100g of ethanol and 10g of ammonia water (30wt%) into the metal Pd nano-sol, and fully stir for 5h at 10°C;

[0070] b1) Take 350.47 g of tetraethyl orthosilicate and add it to the mixture of a1), and fully stir at 10°C for 10 h;

[0071] c1) The mixture obtained in b1 was dried at 120°C for 15h to obtain 101.85g of SiO coated with Pd 2 , recorded as Pd@SiO 2 ;

[0072] 3) Preparation of Pd@ZSM

[0073] a2) Take 101.85g Pd@SiO respectively 2 , 1.44g AlOOH and 254.63g tetrapropylammonium hydroxide mixed and fully milled for 4h;

[0074] b2) Transfer the mixture ...

Embodiment 2

[0080] Pd / ZSM preparation:

[0081] 1) Preparation of Pd nano-sol

[0082] a) Take 20g polyvinylpyrrolidone, 5g Na 2 PdCl 4 Prepare a solution with 400g of water, and stir thoroughly for 1 hour at 15°C;

[0083] b) Take 2.58g NaBH 4 Add to the solution of a), fully stir at 25°C for 12h, then let it stand for 10h, and filter to obtain the nano-sol of metal Pd;

[0084] 2) Pd@SiO 2 preparation of

[0085] a1) Add 50g of ethanol and 20g of ammonia water (30wt%) into the metal Pd nano-sol, and fully stir for 1h at 15°C;

[0086] b1) Add 175.24 g of tetraethyl orthosilicate into the mixture of a1), and stir thoroughly at 30° C. for 15 h;

[0087] c1) The mixture obtained in b1 was dried at 110°C for 20 hours to obtain 51.81g of SiO coated with Pd 2 , recorded as Pd@SiO 2 ;

[0088] 3) Preparation of Pd@ZSM

[0089] a2) Take 51.81g Pd@SiO respectively 2 , 0.72g AlOOH and 233.15g tetrapropylammonium hydroxide were mixed and fully ground for 6h;

[0090] b2) transfer the ...

Embodiment 3

[0095] Pd / ZSM preparation:

[0096] 1) Preparation of Pd nano-sol

[0097] a) Take 30g polyvinylpyrrolidone, 5g Na 2 PdCl 4 Prepare a solution with 350g of water, and fully stir for 6 hours at 5°C;

[0098] b) Take 1.29g NaBH 4 Add to the solution of a), fully stir at 5°C for 2h, then let it stand for 20h, and filter to obtain the nano-sol of metal Pd;

[0099] 2) Pd@SiO 2 preparation of

[0100] a1) Add 150g of ethanol and 25g of ammonia water (30wt%) into the metal Pd nano-sol, and fully stir for 3h at 8°C;

[0101] b1) Add 35.05 g of tetraethyl orthosilicate to the mixture of a1), and stir thoroughly at 25°C for 13 hours;

[0102] c1) The mixture obtained in b1 was dried at 100°C for 10 h to obtain 11.78 g of Pd-coated SiO 2 , recorded as Pd@SiO 2 ;

[0103] 3) Preparation of Pd@ZSM

[0104] a2) Take 11.78g Pd@SiO respectively 2 , 0.13g AlOOH and 58.90g tetrapropylammonium hydroxide are mixed and fully ground for 1h;

[0105] b2) transfer the mixture obtained i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com