A kind of preparation method of xanthate compound

A technology for xanthates and compounds is applied in the field of green and efficient preparation of xanthates, and can solve the problems of waste water, low product yield and purity, loss of organic solvents, and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation of embodiment 1 allyl isopropyl xanthate

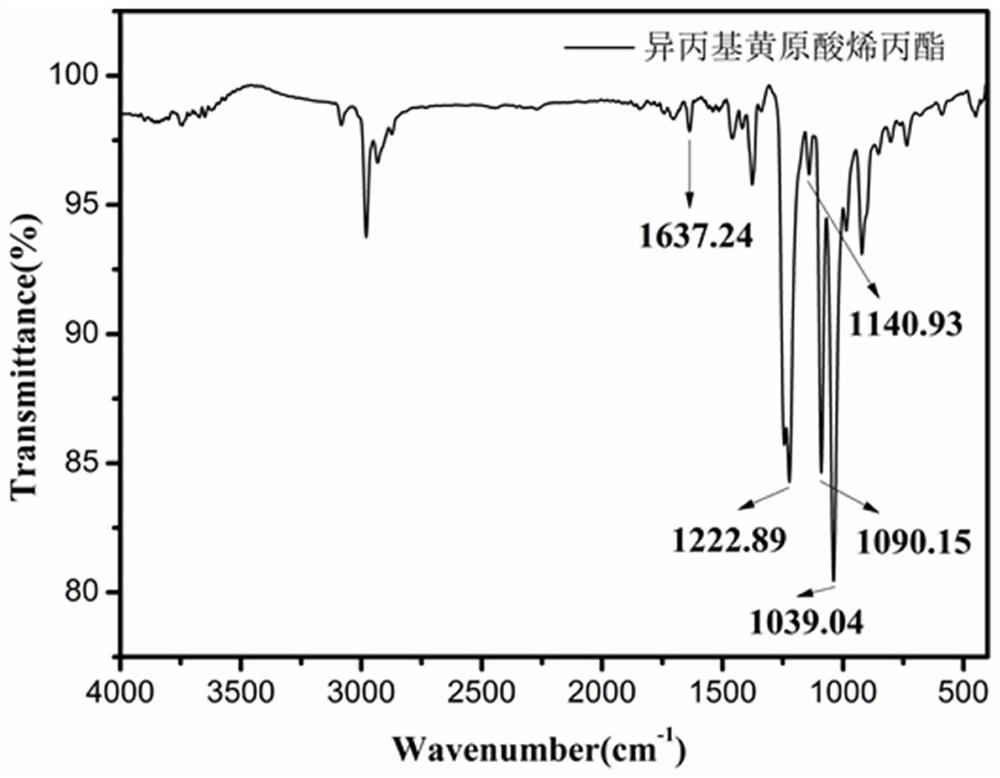

[0033] Add 8.2 parts of allyl chloride with a purity of 98% and 0.6 parts of cetyltrimethylammonium bromide into the reaction kettle, stir evenly and start adding 18.6 parts of isopropyl chloride with a purity of 84.9% in batches after cooling down to 10-20°C. Sodium propyl xanthate, after all the reactants have been added, the temperature rises to 25°C to start the reaction timing. After 6.5h of reaction, the allyl isopropyl xanthate product with a purity of 97.54% is obtained (see figure 2 ), the yield based on sodium isopropyl xanthate is 96.2%. The yield and the purity of the allyl isopropyl xanthate product are significantly higher than the test results of Comparative Example 1.

Embodiment 2-5

[0034] The preparation of embodiment 2-5 allyl isopropyl xanthate

[0035] Change 0.6 parts of cetyltrimethylammonium bromide in Example 1 into triethylamine, benzyltriethylammonium chloride, benzyltrimethylammonium chloride or cetyl trimethylammonium chloride of the same quality respectively Trimethyl ammonium chloride, the allyl isopropyl xanthate product that makes is shown in Table 1.

[0036] Table 1 The influence of the type of phase transfer catalyst on the yield of allyl isopropyl xanthate

[0037]

Embodiment 6

[0038] The preparation of embodiment 6 allyl ethyl xanthate

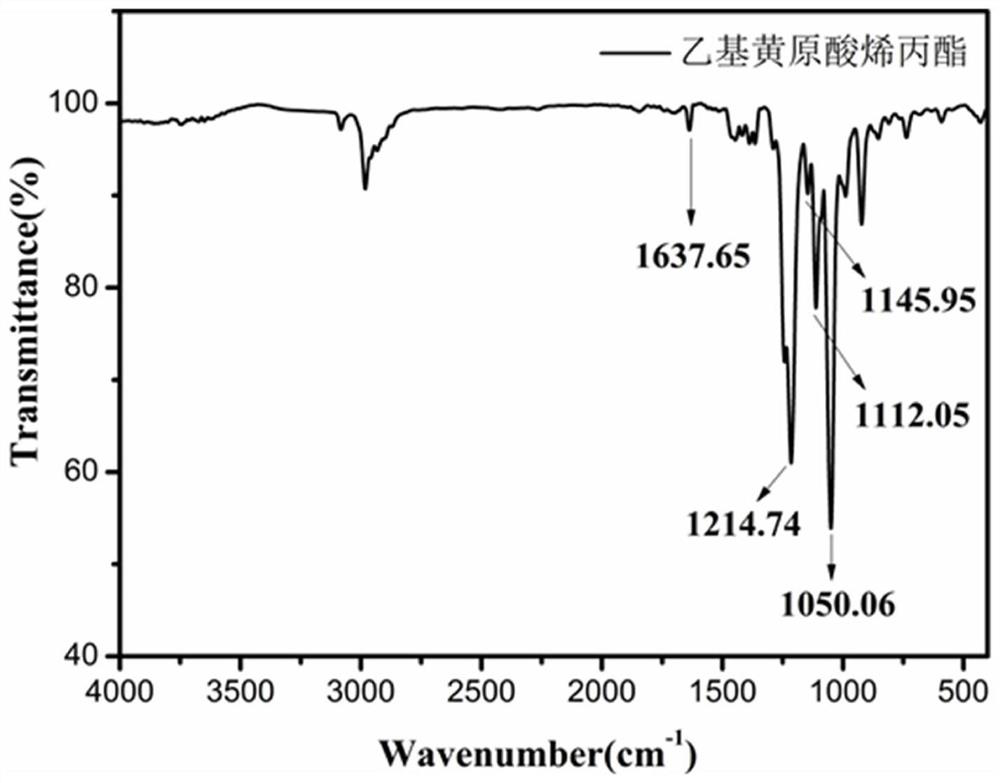

[0039] Add 8.2 parts of allyl chloride with a purity of 98% and 0.6 parts of hexadecyltrimethylammonium bromide into the reaction kettle, stir well and start adding 16 parts of ethyl chloride with a purity of 90% in batches after cooling down to 10-20°C. Sodium xanthate, after all the reactants were added, the temperature rose to 25°C to start the reaction timing, and the reaction was stopped after 6.5 hours of reaction. The purity that makes allyl ethyl xanthate is 98.3% (see figure 1 ), the yield based on sodium ethyl xanthate is 95.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com