Compatilizer and glass fiber reinforced polypropylene composite material

A technology of glass fiber and composite materials, which is applied in the field of glass fiber reinforced polypropylene composite materials and compatibilizers. It can solve the problems of affecting the mechanical properties of products, the inability to apply dark-colored products, and precipitation and stickiness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] An embodiment of the glass fiber reinforced polypropylene composite material of the present invention, the glass fiber reinforced polypropylene composite material described in this embodiment is prepared by the following method:

[0069] Step 1: Preparation of purified PB-1-g-GMA

[0070] a-First weigh 3 parts of monomer glycidyl methacrylate (referred to as GMA), 0.05 part of initiator 2,5-dimethyl-2,5-bis(tert-butyl peroxide)hexane (abbreviated as DHBP) , 0.5 parts of comonomer divinylbenzene (DVB) was dissolved in 30 parts of acetone at 30° C. to obtain a mixed solution A for use.

[0071] b-Add the above mixed solution A to 50 parts of PB-1M8510M and mix and stir evenly at room temperature. After the acetone is completely volatilized, add it to a twin-screw extruder for melt extrusion grafting reaction to obtain PB-1-g-GMA crude compounds. Wherein, the temperature of the twin-screw extruder is 130-150°C.

[0072] c- Take 1 part of PB-1-g-GMA crude product and add...

Embodiment 2

[0076] An embodiment of the glass fiber reinforced polypropylene composite material of the present invention, the glass fiber reinforced polypropylene composite material described in this embodiment is prepared by the following method:

[0077] Step 1: Preparation of purified PB-1-g-GMA

[0078] a-First weigh 6 parts of glycidyl methacrylate monomer (GMA for short), 0.35 parts of initiator 2,5-dimethyl-2,5-bis(tert-butyl peroxide)hexane (DHBP for short) 2 parts of comonomer divinylbenzene (DVB) were dissolved in 50 parts of acetone at 50°C to obtain a mixed solution A for use;

[0079] b- Add the above mixed solution A to 70 parts of PB-1M1500M and mix and stir evenly at room temperature. After the acetone is completely volatilized, add it to a twin-screw extruder for melt extrusion grafting reaction to obtain PB-1-g-GMA crude compounds. Wherein, the temperature of the twin-screw extruder is 130-150°C;

[0080] c- Take 1 part of PB-1-g-GMA crude product and add it to 50 par...

Embodiment 3

[0084] An embodiment of the glass fiber reinforced polypropylene composite material of the present invention, the glass fiber reinforced polypropylene composite material described in this embodiment is prepared by the following method:

[0085] Step 1: Preparation of purified PB-1-g-GMA

[0086] a-First weigh 4 parts of monomer glycidyl methacrylate (referred to as GMA), 0.15 parts of initiator 2,5-dimethyl-2,5-bis(tert-butyl peroxide)hexane (abbreviated as DHBP) 1. Dissolve 1 part of comonomer divinylbenzene (DVB) in 37 parts of acetone at 37° C. to obtain mixed solution A for use.

[0087] b-Add the above mixed solution A to 55 parts of PB-1M1200M, mix and stir evenly at room temperature, and after the acetone is completely volatilized, add it to a twin-screw extruder for melt extrusion grafting reaction to obtain PB-1-g-GMA crude compounds. Wherein, the temperature of the twin-screw extruder is 130-150°C.

[0088] c- Take 1 part of PB-1-g-GMA crude product and add it to ...

PUM

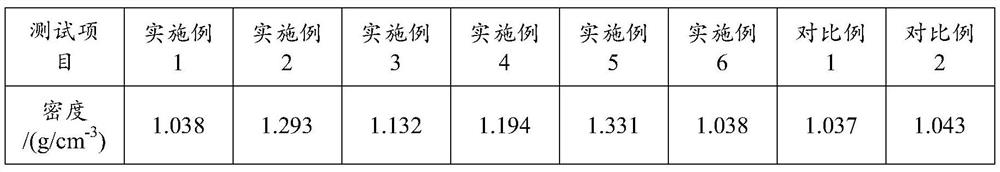

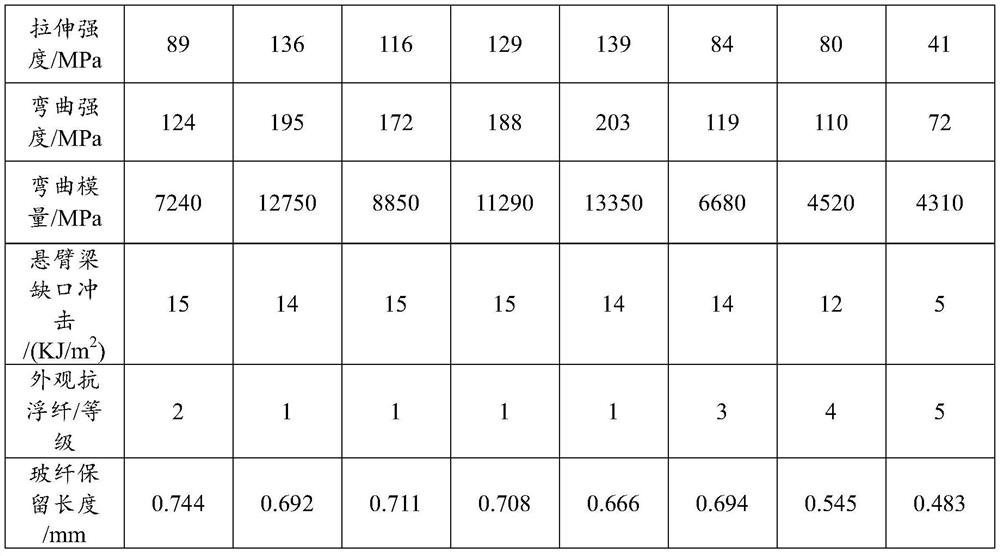

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com