Driving test device and driving test method for electrochemical driving

A driving test and electrochemical technology, which is applied in measuring devices, measuring electrical variables, measuring resistance/reactance/impedance, etc., can solve problems such as large errors, long time consumption, and inability to drive signal real-time output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

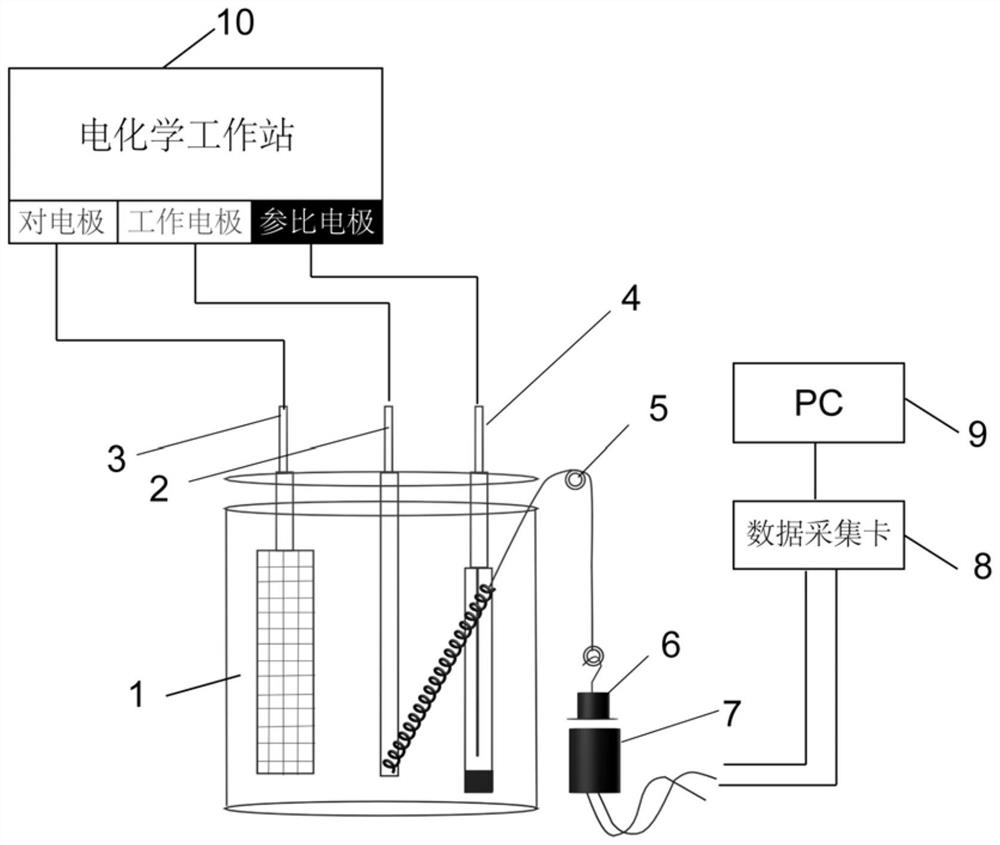

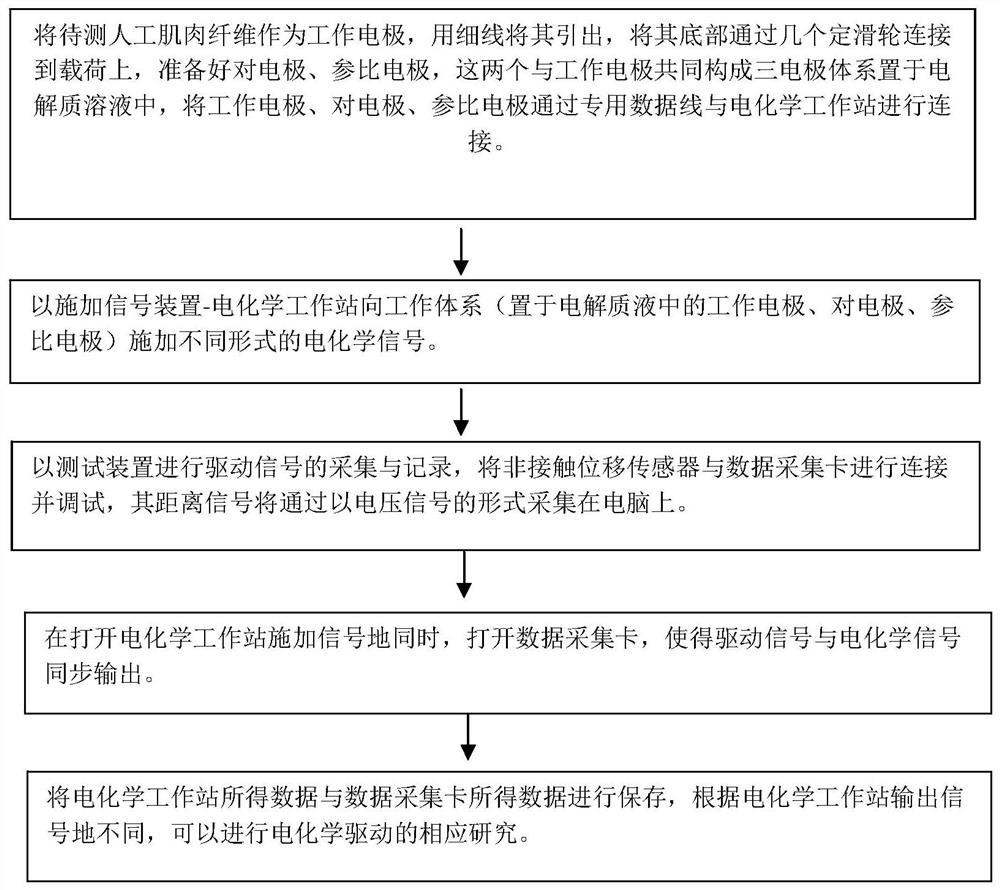

[0045] The carbon nanotube fiber prepared by the floating catalytic method is formed by excessive twisting to form a helical structure, so as to obtain the carbon nanotube artificial muscle fiber, which is used as the working electrode; the counter electrode and the reference electrode are respectively sandwiched with activated carbon nanotubes Platinum mesh and Ag / Ag for tube thin films + Electrode, electrolyte solution using 0.2M tetraethyl ammonium tetrafluoroborate (TEA · BF 4 ) dissolved in propylene carbonate;

[0046] Connect the working electrode, counter electrode, and reference electrode to the electrochemical workstation through a dedicated data line;

[0047] Debug the data acquisition card in advance to keep the balance between the load and the non-contact displacement sensor;

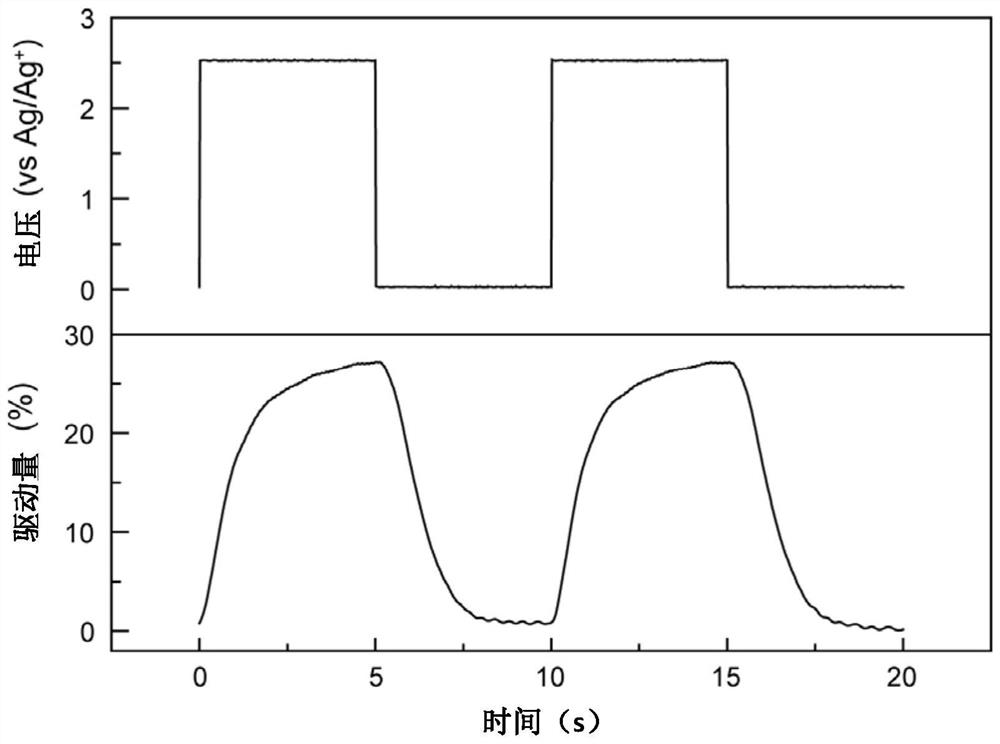

[0048] Adjust the parameters in the electrochemical workstation, set the working mode of the electrochemical workstation to chronoamperometry, set the high voltage to 2.5V, the low volta...

Embodiment 2

[0051] The carbon nanotube fiber prepared by the floating catalytic method is formed by excessive twisting to form a helical structure, so as to obtain the carbon nanotube artificial muscle fiber, which is used as the working electrode; the counter electrode and the reference electrode are respectively sandwiched with activated carbon nanotubes Platinum mesh and Ag / Ag for tube thin films + Electrode, electrolyte solution using 0.2M tetraethyl ammonium tetrafluoroborate (TEA · BF 4 ) dissolved in propylene carbonate;

[0052] Connect the working electrode, counter electrode, and reference electrode to the electrochemical workstation through a dedicated data line;

[0053] Debug the data acquisition card in advance to keep the balance between the load and the non-contact displacement sensor;

[0054] The parameters are regulated in the electrochemical workstation, the working mode of the electrochemical workstation is set as cyclic voltammetry, the high voltage is set to 2.5V,...

Embodiment 3

[0057] The carbon nanotube fiber prepared by the floating catalytic method forms a helical structure through excessive twisting, so as to obtain the carbon nanotube artificial muscle fiber, which is used as the working electrode. The counter electrode and reference electrode are platinum mesh and Ag / Ag + Electrode, electrolyte solution using 0.2M tetraethyl ammonium tetrafluoroborate (TEA · BF 4 ) dissolved in propylene carbonate;

[0058] Connect the working electrode, counter electrode, and reference electrode to the electrochemical workstation through a dedicated data line;

[0059] Debug the data acquisition card in advance to keep the balance between the load and the non-contact displacement sensor;

[0060] Adjust the parameters in the electrochemical workstation, set the working mode of the electrochemical workstation to chronoamperometry, set the frequency to 0.1Hz, and the number of cycles to 4, and change different voltages (1V, 1.5V, 2V, 2.5V ,3V), the data acqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com