Method for purifying Fe3O4 nano-particles taking oleic acid as ligand and synthesizing magnetic nano-stirrers and application

A nanoparticle, magnetic nanotechnology, applied in the direction of nanotechnology, magnetic materials, magnetic objects, etc. for materials and surface science

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

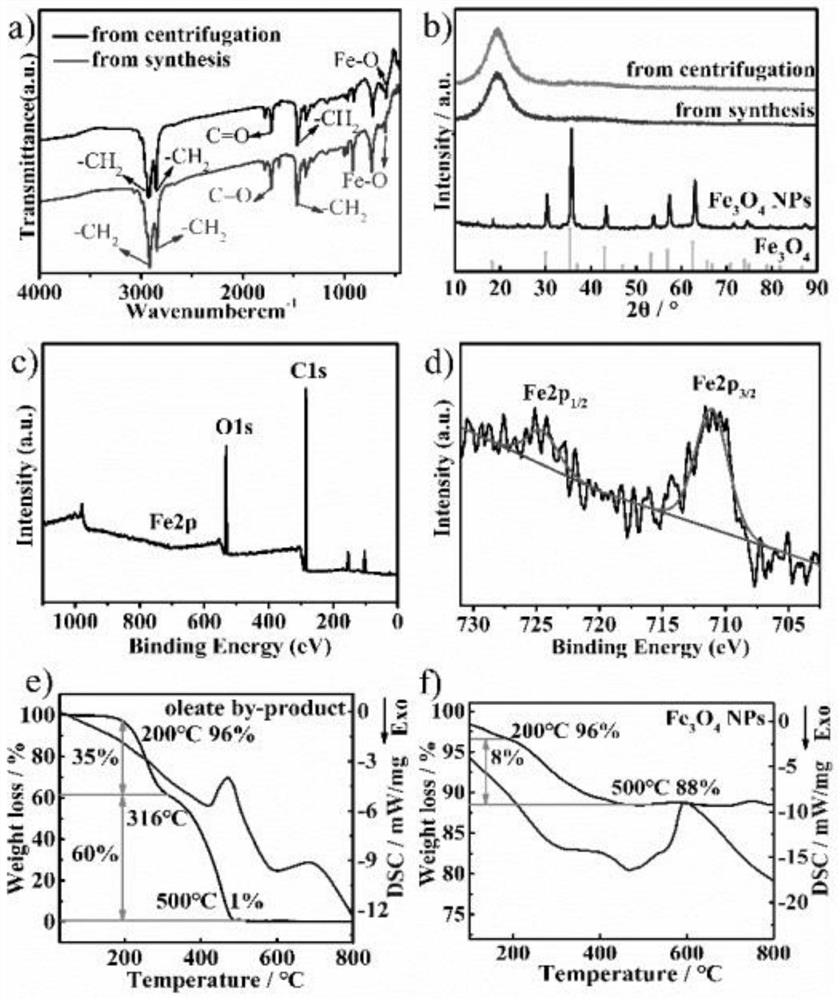

[0052] A kind of Fe with oleic acid as ligand 3 o 4 A method for purifying nanoparticles and synthesizing a magnetic nanostirrer, comprising the following steps:

[0053] (1) Weigh 3.65g of sodium oleate and add it to a mixed solution of 28mL ethanol, deionized water, and n-hexane, stir until fully dissolved, then add 1.08g of ferric chloride hexahydrate, heat to 70°C and reflux for 4h . After cooling to room temperature, extract with 10mL of water, rotary steam the extracted solution to obtain a reddish-brown waxy solid which is iron oleate mixture, then stir the mixture with 20.57g of oleic acid and octadecene, and heat to 320 Keep at ℃ for 30min, cool to room temperature, precipitate nanospheres with 50mL ethanol, and disperse the precipitate with 50mL chloroform to obtain Fe with a particle size of 10nm 3 o 4 nanosphere solution.

[0054] (2) Analyze the physical properties of the by-products produced in the synthesis of magnetic nanoparticles, so as to formulate thei...

Embodiment 2

[0060] A kind of Fe with oleic acid as ligand 3 o 4 The method for purifying and synthesizing the magnetic nano-stirrer of nanoparticles comprises the following steps:

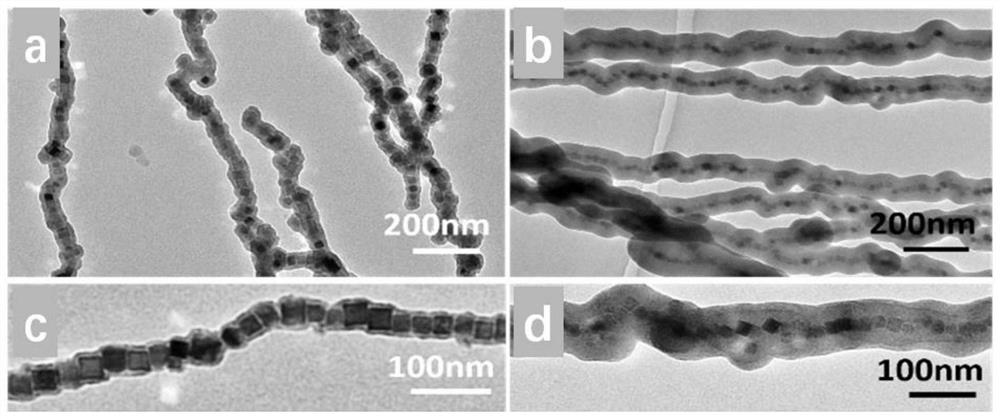

[0061] (1) Add 0.706g iron acetylacetonate to 10.4g oleic acid, 4-phenylbenzoic acid, dibenzyl ether mixed solution, put it in a three-neck round bottom flask, keep it for 1h, then heat it to 290°C for 30min, cool to At room temperature, wash with a mixed solution of 40mL toluene and 10mL n-hexane, centrifuge and disperse to obtain 25nm Fe 3 o 4 nanocube.

[0062] (2) Measure Fe in 1mL step (1) 3 o 4 The nanocube solution was dispersed in 3mL of toluene and soaked for 36h.

[0063] (3) Fe processed by step (2) 3 o 4 The nanocubes were centrifuged at 500 g, and the resulting precipitate was dispersed in 1 mL of chloroform to obtain Fe 3 o 4 A solution of nanocubes.

[0064] (4) 500 μL of Fe from step (3) 3 o 4 Nanocube solution, 0.3g of citric acid, 12mL of a mixed solution of 1,2-dichlorobenzene a...

Embodiment 3

[0067] A kind of Fe with oleic acid as ligand 3 o 4 The method for purifying and synthesizing the magnetic nano-stirrer of nanoparticles comprises the following steps:

[0068] (1) 10nm Fe 3 o 4 The preparation method of the nanosphere solution is the same as in Example 1.

[0069] (2) The nanosphere soaking method is the same as in Example 1.

[0070] (3) Fe processed by step (2) 3 o 4 The nanosphere solution was centrifuged at 500 g, and the obtained precipitate was dispersed in 1 mL of chloroform to obtain Fe 3 o 4 solution of nanospheres.

[0071] (4) The ligand exchange method of the nanosphere solution is the same as in Example 1.

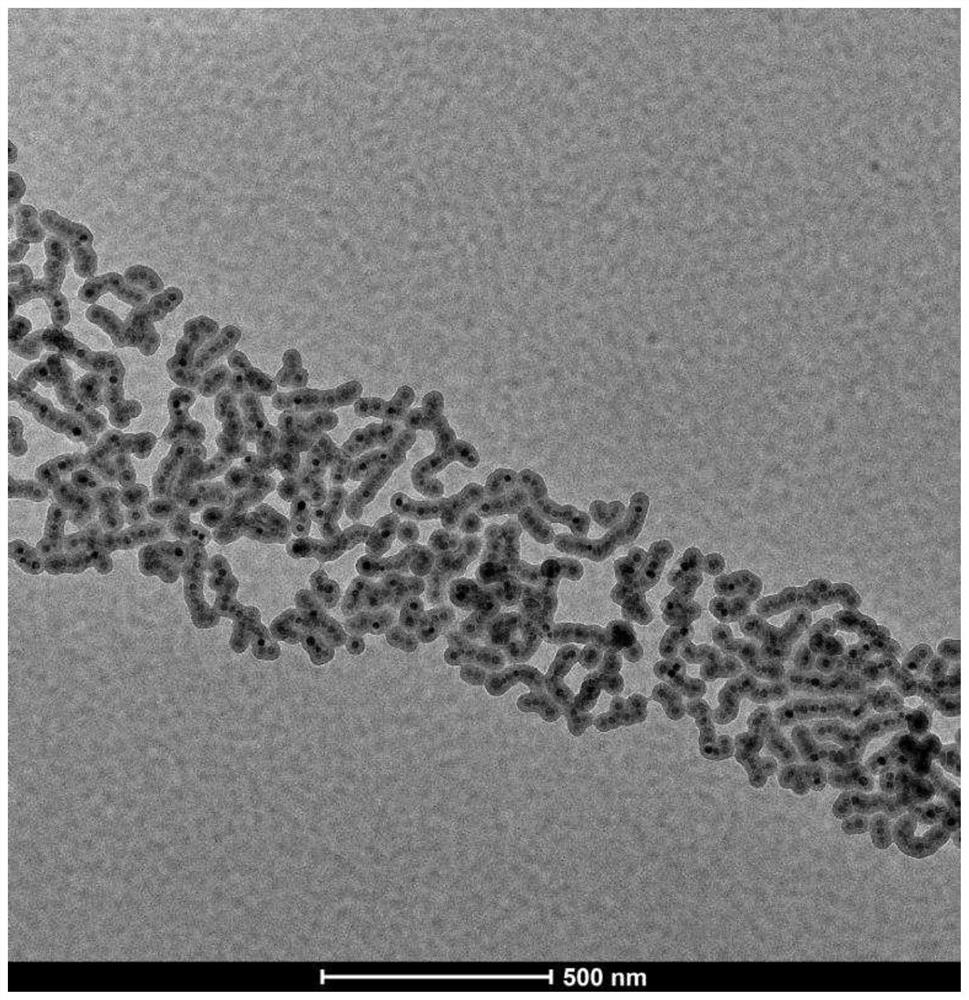

[0072] (5) The assembly process is the same as that in Example 1. A nano-stirrer with a width of ~50nmm and a length of ~280nm was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com