Antibacterial absorbable medical soft tissue suture line and preparation method and application thereof

A suture and soft tissue technology, applied in the field of medical suture, can solve the problems of insufficient mechanical strength, unfavorable large-scale application, easy to lose water and difficult to place and store, achieve excellent adaptability, reduce secondary injuries, and avoid secondary damage. The effect of secondary damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A preparation method of antibacterial absorbable suture, comprising the following steps:

[0053] (1) 2.5g chitosan (molecular weight 1000) is dissolved in 40ml dimethyl sulfoxide (DMSO), under nitrogen protection, add 1.5g p-aldehyde benzoic acid, 10mg 4-dimethylaminopyridine (DMAP), 5 mg of dicyclohexylcarbodiimide, reacted at room temperature 25°C for 24 hours, added water to precipitate, filtered, washed several times with water, dried and dialyzed with a dialysis bag with a molecular weight of 1000 for 3 days to obtain graft-modified aldehydated chitosan ;

[0054] (2) 0.6g carboxymethyl chitosan powder is dissolved in the deionized water of 10ml, 800rpm stirs 4h and dissolves completely and forms light yellow solution;

[0055] (3) Disperse 0.1 g of graft-modified aldehydated chitosan into 5 ml of deionized water, ultrasonically disperse it for 10 min, and slowly add it to the carboxymethyl chitosan solution, then Stir at 800rpm for 2h to a uniform solution to o...

Embodiment 2

[0059] A preparation method of antibacterial absorbable suture, comprising the following steps:

[0060] (1) 2.5g chitosan (molecular weight 1000) is dissolved in 40ml dimethyl sulfoxide (DMSO), under nitrogen protection, add 1.5g p-aldehyde benzoic acid, 10mg 4-dimethylaminopyridine (DMAP), 5 mg of dicyclohexylcarbodiimide, reacted at room temperature 25°C for 24 hours, added water to precipitate, filtered, washed several times with water, dried and dialyzed with a dialysis bag with a molecular weight of 1000 for 3 days to obtain graft-modified aldehydated chitosan ;

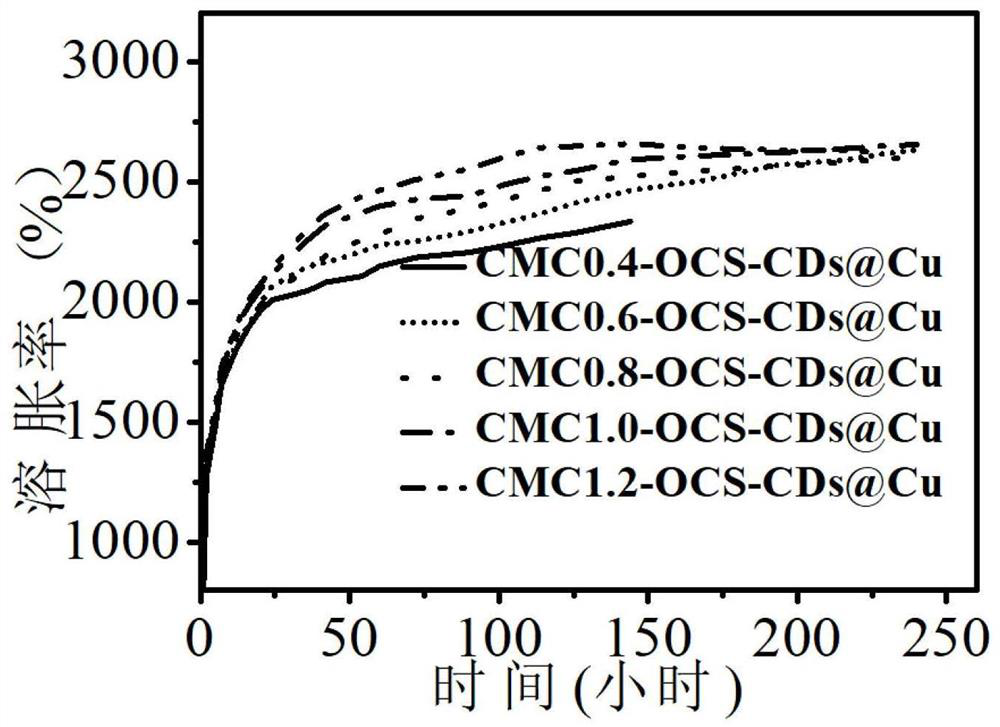

[0061] (2) Dissolve 0.4, 0.6, 0.8, 1.0, 1.2g of carboxymethyl chitosan powder in 10ml of deionized water respectively, and stir at 800rpm for 4h to completely dissolve to form a light yellow solution;

[0062] (3) Disperse 0.1 g of graft-modified aldehydated chitosan into 5 ml of deionized water, ultrasonically disperse it for 10 min, and slowly add it to the carboxymethyl chitosan solution, then Stir at 800r...

Embodiment 3

[0067] A preparation method of antibacterial absorbable suture, comprising the following steps:

[0068] (1) 2.5g chitosan (molecular weight 1000) is dissolved in 40ml dimethyl sulfoxide (DMF), and 1.5g p-aldehyde benzoic acid, 10mg 4-dimethylaminopyridine (DMAP) are added under nitrogen protection, 5 mg of dicyclohexylcarbodiimide, reacted at room temperature 25°C for 24 hours, added water to precipitate, filtered, washed several times with water, dried and dialyzed with a dialysis bag with a molecular weight of 1000 for 3 days to obtain graft-modified aldehydated chitosan ;

[0069] (2) 1.2g carboxymethyl chitosan powder is dissolved in the deionized water of 10ml, 800rpm stirs 4h and dissolves completely and forms light yellow solution;

[0070] (3) Disperse 0.2 g of graft-modified aldehylated chitosan into 5 ml of deionized water, ultrasonically disperse it for 10 min, and slowly add it to the carboxymethyl chitosan solution, then Stir at 800rpm for 2h to a uniform solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com