Repair welding method for reducing welding cracks of magnesium rare earth alloy casting

A magnesium rare earth alloy and welding crack technology, which is applied in the field of repair welding to reduce welding cracks of magnesium rare earth alloy castings and repair welding of magnesium rare earth alloys, can solve the problems of reducing the mechanical properties of the repair welding area, so as to avoid cracking in the shrinkage stress field and improve Mechanical properties, the effect of increasing the grain boundary volume fraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

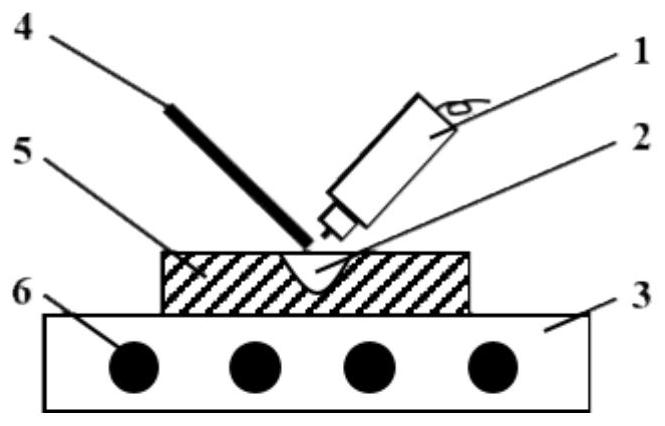

[0034] Taking the Mg-10wt%Gd-3wt%Y magnesium rare earth alloy casting as an example (wt% refers to the percentage of the composition in the total mass of the prepared magnesium alloy) for repair welding, the operation is shown as figure 1 shown.

[0035] Inspection of Mg-10wt%Gd-3wt%Y magnesium rare earth alloy castings through X-ray flaw detection, marking the defective parts and drilling and digging with pneumatic milling cutter to form grooves 2 to be repaired to ensure that The shape of the repair welding groove 2 is boat-shaped and has a smooth transition with the base metal surface. After the defects are removed, the casting is subjected to solid solution treatment. The solution treatment temperature is 480° C., and the solution time is 15 hours. After the solution treatment is completed, the surface of the repair welding groove 2 is polished to brightness with sandpaper. Then place the magnesium rare earth alloy casting 5 after solid solution treatment on the heating p...

Embodiment 2

[0038] Taking Mg-4wt%Y-2wt%Nd-1wt%Gd magnesium rare earth alloy casting as an example for repair welding.

[0039] Inspection of Mg-4wt%Y-2wt%Nd-1wt%Gd magnesium rare earth alloy castings through X-ray flaw detection, mark the defective parts and drill them with pneumatic milling cutter to ensure the shape of repair welding groove It is ship-shaped and has a smooth transition with the base metal surface. After the defects are removed, the casting is subjected to solid solution treatment. The solution treatment temperature is 500°C, and the solution time is 10 hours. After the solution treatment is completed, the surface of the groove to be repaired is polished to brightness with sandpaper. Then place the casting on the heating platform. After the temperature of the heating platform rises to the set temperature of 170°C, use the ultra-high frequency pulsed AC arc tungsten argon arc welding to fill the groove. The current waveform is a sine wave. , the pulse frequency is 10000H...

Embodiment 3

[0042] Taking the Mg-5wt%Y-2.5wt%Nd-1wt%Gd magnesium rare earth alloy casting as an example, repair welding is carried out.

[0043] Inspection of Mg-5wt%Y-2.5wt%Nd-1wt%Gd magnesium rare earth alloy castings through X-ray flaw detection, mark the defective parts and drill them with pneumatic milling cutter to ensure repair welding grooves The shape is boat-shaped and has a smooth transition with the base metal surface. After the defects are removed, the casting is subjected to solid solution treatment. The solution treatment temperature is 530°C, and the solution time is 6 hours. After the solution treatment is completed, the surface of the groove to be repaired is polished to brightness with sandpaper. Then place the casting on the heating platform. After the temperature of the heating platform rises to the set temperature of 250°C, use the ultra-high frequency pulsed AC arc tungsten argon arc welding to fill the groove. The current waveform is a triangular wave. The pulse f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com