Columnar activated coke based on waste plastic binder and preparation method of columnar activated coke

A technology of waste plastics and binders, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of low adsorption capacity, small specific surface area, high production cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

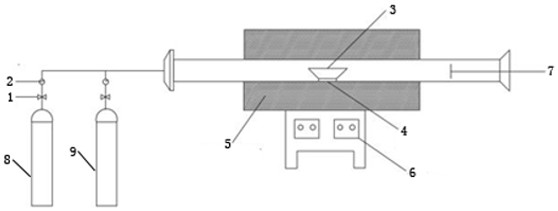

Image

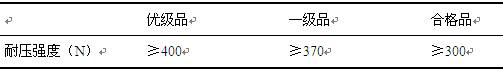

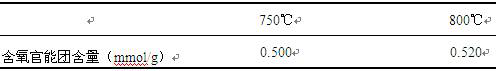

Examples

Embodiment 1

[0026] A method for preparing columnar active coke based on waste plastic binder, comprising the following steps:

[0027] (1) Raw coal crushing: crush lignite and coking coal into raw coal particles below 15mm;

[0028] (2) Grinding and screening: Grinding and screening lignite and coking coal particles to obtain 180-mesh coal powder;

[0029] (3) Binder: use phenolic plastic as binder, grind and sieve to obtain 180 mesh powder;

[0030] (4) Drying: Dry lignite, coking coal and phenolic plastic at 110°C for 6 hours;

[0031] (5) Kneading: Mix lignite, coking coal and phenolic plastic at room temperature at a mass ratio of 65:25:20 for 20 minutes;

[0032] (6) Molding: the mixture is pressed into shape under a pressure of 15Mpa;

[0033] (7) Carbonization: The molding material is carbonized in a tube furnace, the carbonization temperature is 550°C, and the carbonization time is 30 minutes;

[0034] (8) Activation: Activate in a tube furnace, the activation temperature is 7...

Embodiment 2

[0046] A method for preparing columnar active coke based on waste plastic binder, comprising the following steps:

[0047] (1) Raw coal crushing: crush lignite and coking coal into raw coal particles below 15mm;

[0048] (2) Grinding and screening: Grinding and screening lignite and coking coal particles to obtain 180-mesh coal powder;

[0049] (3) Binder: use phenolic plastic as binder, grind and sieve to obtain 180 mesh powder;

[0050] (4) Drying: Dry lignite, coking coal and phenolic plastic at 110°C for 6 hours;

[0051] (5) Kneading: Mix lignite, coking coal and phenolic plastic at room temperature at a mass ratio of 65:25:30 for 20 minutes;

[0052] (6) Molding: the mixture is pressed into shape under a pressure of 15Mpa;

[0053] (7) Carbonization: The molding material is carbonized in a tube furnace, the carbonization temperature is 550°C, and the carbonization time is 30 minutes;

[0054] (8) Activation: Activate in a tube furnace, the activation temperature is 7...

Embodiment 3

[0064] A method for preparing columnar active coke based on waste plastic binder, comprising the following steps:

[0065] (1) Raw coal crushing: crush lignite and coking coal into raw coal particles below 15mm;

[0066] (2) Grinding and screening: Grinding and screening lignite and coking coal particles to obtain 180-mesh coal powder;

[0067] (3) Binder: use phenolic plastic as binder, grind and sieve to obtain 180 mesh powder;

[0068](4) Drying: Dry lignite, coking coal and phenolic plastic at 110°C for 6 hours;

[0069] (5) Kneading: Mix lignite, coking coal and phenolic plastic at room temperature at a mass ratio of 65:25:40 for 20 minutes;

[0070] (6) Molding: the mixture is pressed into shape under a pressure of 15Mpa;

[0071] (7) Carbonization: The molding material is carbonized in a tube furnace, the carbonization temperature is 550°C, and the carbonization time is 30 minutes;

[0072] (8) Activation: Activate in a tube furnace, the activation temperature is 75...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com