Cement stabilized macadam micro-cracking additive and application thereof

A cement-stabilized crushed stone and additive technology, applied in liquid/fluid solid measurement, instruments, measuring devices, etc., can solve problems such as poor aggregate strength and particle shape, bottlenecks in research, uneven support, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

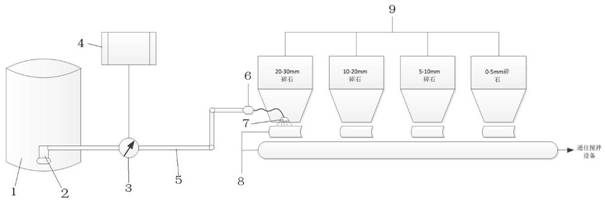

Method used

Image

Examples

Embodiment 1

[0035] A cement-stabilized crushed stone microcracking additive, comprising main components, auxiliary components and water; the main components are fatty acid glycerides, polyoxyethylene ether-20 oleoyl ricinate; the auxiliary The components are emulsifiers; based on 100 parts by weight, the parts by weight of each component are: 45 parts of fatty acid glycerides, 8 parts of polyoxyethylene ether-20 oleoyl ricinate, 20 parts of emulsifiers, The balance is water. Described emulsifier adopts tallow tetramine.

Embodiment 2

[0037]A cement-stabilized crushed stone microcracking additive, comprising main components, auxiliary components and water; the main components are fatty acid glycerides, polyoxyethylene ether-20 oleoyl ricinate; the auxiliary The components are emulsifiers; based on 100 parts by weight, the parts by weight of each component are: 50 parts of fatty acid glycerides, 10 parts of polyoxyethylene ether-20 oleoyl ricinate, 25 parts of emulsifiers, The balance is water. Described emulsifier adopts tallow tetramine.

Embodiment 3

[0039] A cement-stabilized crushed stone microcracking additive, comprising main components, auxiliary components and water; the main components are fatty acid glycerides, polyoxyethylene ether-20 oleoyl ricinate; the auxiliary The components are emulsifiers; based on 100 parts by weight, the parts by weight of each component are: 45 parts of fatty acid glycerides, 10 parts of polyoxyethylene ether-20 oleoyl ricinate, 20 parts of emulsifiers, The balance is water. Described emulsifier adopts tallow tetramine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com