Preparation method of p-aminosalicylic acid

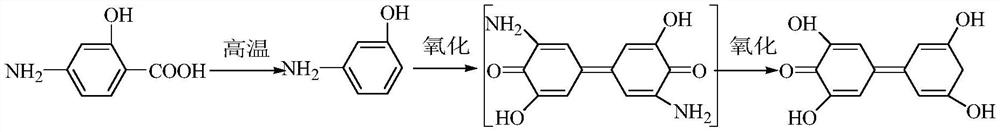

A technology of p-aminosalicylic acid and sodium aminosalicylic acid, applied in the field of preparation of p-aminosalicylic acid, can solve the problems of decreased yield, decreased purity of aminosalicylic acid, generation of impurities, etc., and can reduce drying and heating less time, fewer process steps and higher yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation method of p-aminosalicylic acid, comprising:

[0026] Add sodium p-aminosalicylate dihydrate into the mixed phase of water and organic solvent, the organic solvent includes lower alcohol; add acid solution to adjust pH=2.5-4.0, filter, wash and dry.

[0027] Specifically: sodium p-aminosalicylate dihydrate is added into the mixed phase of water and organic solvent, and the organic solvent includes lower alcohol. Preferably, antioxidants and complexing agents are added to the mixed phase and stirred for 10-30 minutes. The resulting system can be a solid-liquid coexistence, or a clear liquid phase, without complete dissolution. Add acid solution to adjust pH=2.5-4.0; filter, wash and dry to obtain p-aminosalicylic acid.

[0028] Specific steps are as follows:

[0029] Measure water and organic solvent separately and mix.

[0030] Wherein, the water may be selected from drinking water, purified water or water for injection, preferably purified water. Whe...

Embodiment 2

[0038] The present invention provides a method for preparing p-aminosalicylic acid. The method in Example 2 is basically the same as the method in Example 1, the difference mainly lies in the type of organic solvent and the ratio of different types of organic solvents in the organic solvent.

[0039] Adding sodium p-aminosalicylate dihydrate into the mixed phase of water and organic solvents, the organic solvents include lower alcohols and esters; adding acid solution to adjust pH=2.5-4.0, filtering, washing and drying.

[0040] Specifically: sodium p-aminosalicylate dihydrate is added to the mixed phase of water and organic solvents, and the organic solvents include lower alcohols and esters. Preferably, antioxidants and complexing agents are added to the mixed phase and stirred for 10-30 minutes. The resulting system can be a solid-liquid coexistence, or a clear liquid phase, without complete dissolution. Add acid solution to adjust pH=2.5-4.0; filter, wash and dry to obtai...

Embodiment 3

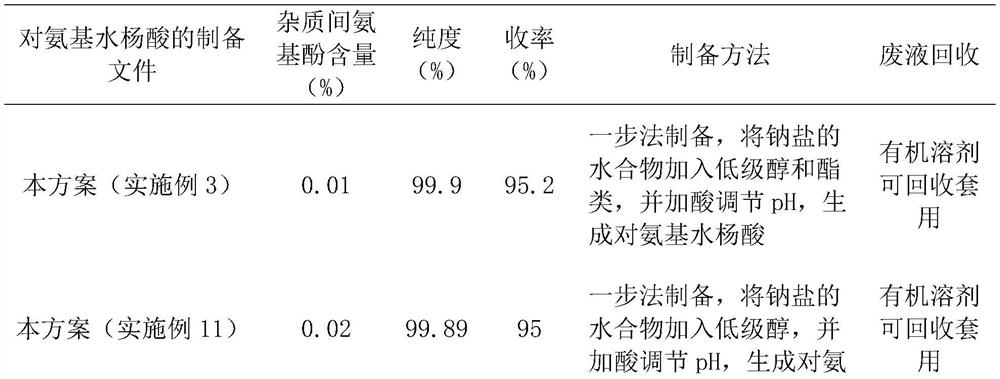

[0050] Add 200mL of water, 200mL of ethanol and 20mL of ethyl acetate into a clean reaction bottle, stir, add 100g of sodium p-aminosalicylate dihydrate, about 0.5g of EDTA, and about 0.5g of sodium sulfite, and stir to dissolve. Add acid solution dropwise, adjust pH=3.5, and stir for 5-10 minutes. Re-measure the pH and control the pH to 3.0. Filter, wash, filter and dry to obtain p-aminosalicylic acid, the purity of the obtained p-aminosalicylic acid is 99.9%, and the yield is 95.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com