Resource utilization method of 3-methyl-2-nitrobenzoic acid wastewater

A nitrobenzoic acid and resource-based technology, which is applied in liquid carbon-containing fuels, fuel additives, petroleum industry, etc. The effect of peeling off the surface and improving the safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

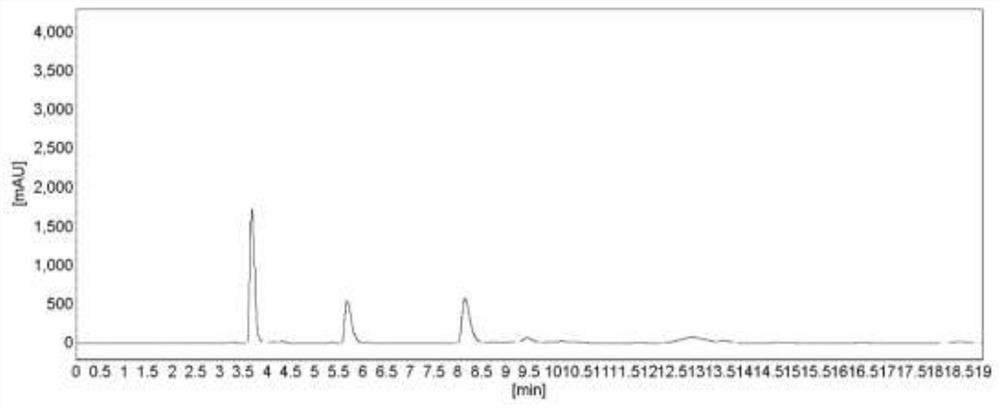

Image

Examples

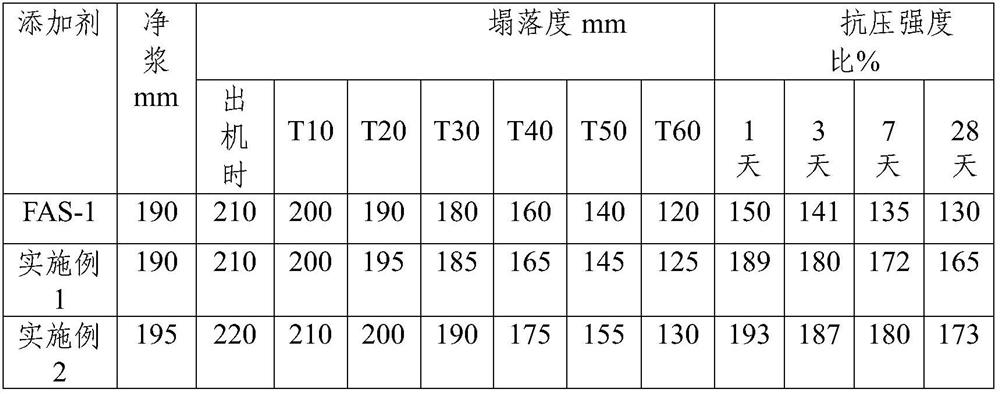

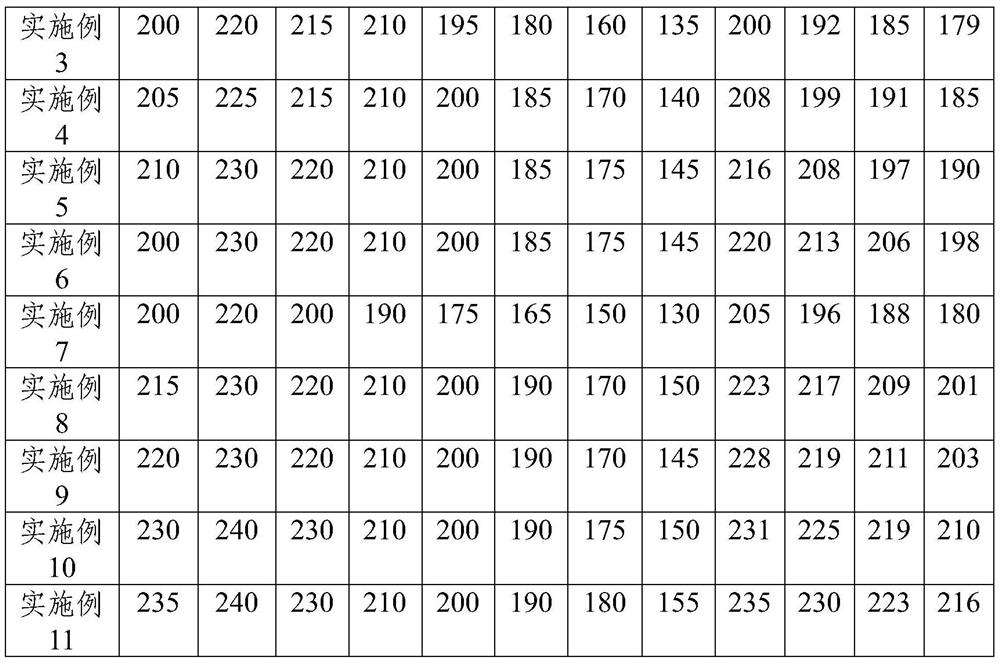

Embodiment 1

[0029] A method for resource utilization of 3-methyl-2-nitrobenzoic acid waste water, raw materials are calculated in parts by mass, comprising the following steps:

[0030] Add 50 parts of 3-methyl-2-nitrobenzoic acid waste water (solid content is 18wt%) to the reactor, then add 350 parts of clear water, after stirring and mixing evenly, add 156 parts of sodium sulfite (85wt%), stir and mix evenly , adding a certain amount of sodium hydroxide solution (32wt%) to adjust the pH value to 8.5-9.5, sulfonation and heat preservation for 30min, and the sulfonation temperature does not exceed 50°C. Then dropwise add 100 parts of acetone, the temperature during the acetone dropping process does not exceed 55°C, and the dropwise duration is 30min; The temperature during the addition process does not exceed 95°C; after the dropwise addition, condense at 90-96°C for 2 hours, and cool down at the end of the heat preservation to obtain the dispersant.

Embodiment 2

[0032] A method for resource utilization of 3-methyl-2-nitrobenzoic acid waste water, raw materials are calculated in parts by mass, comprising the following steps:

[0033]Add 100 parts of 3-methyl-2-nitrobenzoic acid waste water (solid content is 15wt%) to the reactor, then add 300 parts of clear water, after stirring and mixing evenly, add 156 parts of sodium sulfite (85wt%), stir and mix evenly , adding a certain amount of sodium hydroxide solution (32wt%) to adjust the pH value to 8.5-9.5, sulfonation and heat preservation for 30min, and the sulfonation temperature does not exceed 50°C. Then dropwise add 100 parts of acetone, the temperature in the process of adding acetone does not exceed 55°C, and the time for dropping is 40 minutes; During the addition process, the temperature does not exceed 95°C; after the dropwise addition, condense at 90-96°C for 2 hours, and then cool down after the end of the heat preservation.

Embodiment 3

[0035] A method for resource utilization of 3-methyl-2-nitrobenzoic acid waste water, raw materials are calculated in parts by mass, comprising the following steps:

[0036] Add 150 parts of 3-methyl-2-nitrobenzoic acid waste water (solid content is 13wt%) to the reactor, then add 250 parts of clear water, after stirring and mixing evenly, add 156 parts of sodium sulfite (85wt%), stir and mix evenly , adding a certain amount of sodium hydroxide solution (32wt%) to adjust the pH value to 8.5-9.5, sulfonation and heat preservation for 30min, and the sulfonation temperature does not exceed 50°C. Then dropwise add 100 parts of acetone, the temperature during the dropping of acetone does not exceed 55°C, and the time for dropping is 20 minutes; During the dropping process, the temperature does not exceed 95°C; after the dropwise addition, condense at 90-96°C for 1 hour, and cool down at the end of the holding to obtain the dispersant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com