A kind of waterborne polyurethane resin for coating and preparation method thereof

A technology of water-based polyurethane and resin, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor performance of water-based polyurethane, inconvenient on-site construction, high viscosity of oil-based polyurethane, etc., and achieve fast surface drying of the coating film, which is beneficial to the site The effect of construction and long pot life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] A second aspect of the present invention provides the above-mentioned preparation method of the water-based polyurethane resin, which comprises the following steps:

[0040] (1) Under nitrogen protection, diisocyanate is added into the reaction flask, the temperature is controlled at 50-70° C., and the diol is added dropwise to react with it, and the reaction is stopped when the -NCO value reaches the theoretical value to obtain compound A;

[0041] (2) Under nitrogen protection, add compound A into the reaction flask, control the temperature to 60-80°C, and dropwise add the N-methylpyrrolidone solution of dimethylolpropionic acid (DMPA) to react with it, and the detection-NCO value reaches the theoretical value That is, stop the reaction to obtain compound B;

[0042] (3) Under nitrogen protection, under the condition of avoiding light, add an excess of 5-20wt% diamine into the reaction flask, at room temperature, add compound B dropwise to react with it, after detecti...

Embodiment 1

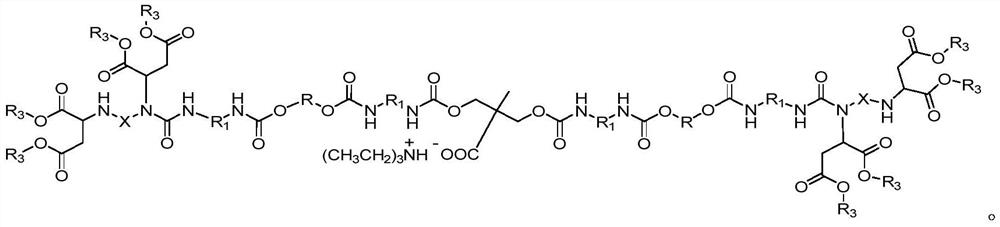

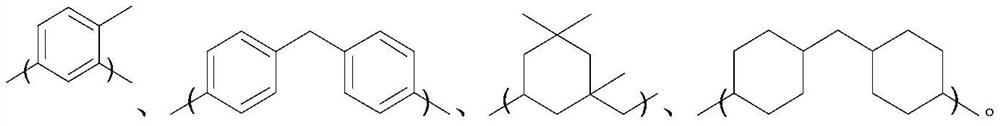

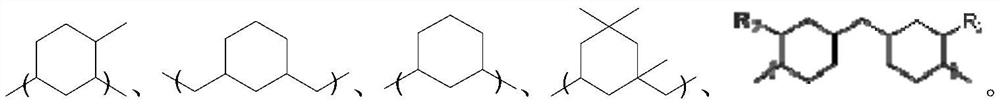

[0065] Example 1 : A water-based polyurethane resin is provided, which has the following structural formula:

[0066]

[0067] The preparation method of above-mentioned water-based polyurethane resin comprises the following steps:

[0068] (1) Under nitrogen protection, weigh 666.8g IPDI into the reaction flask, control the temperature to 60±5°C, slowly add 300g PEG200 dropwise to react with it, and stop the reaction when the detection-NCO value reaches the theoretical-NCO value to obtain compound A1;

[0069] (2) Under nitrogen protection, weigh 580g of compound A1 into a reaction flask, control the temperature to 70±5°C, slowly add 60.3g of DMPA NMP solution dropwise to react with it, and stop the reaction when the detection-NCO value reaches the theoretical-NCO value to obtain compound B1;

[0070] (3) nitrogen protection, weigh 548.5g of diamine and add it to the reaction flask, at room temperature, slowly add 640.3g of compound B1 dropwise to react with it, detect the...

Embodiment 2

[0074] Example 2 : A water-based polyurethane resin is provided, which has the following structural formula:

[0075]

[0076] The preparation method of above-mentioned water-based polyurethane resin comprises the following steps:

[0077] (1) Under nitrogen protection, weigh 666.8g IPDI into the reaction flask, control the temperature to 60±5°C, slowly add 600g PEG400 dropwise to react with it, and stop the reaction when the detection-NCO value reaches the theoretical-NCO value to obtain compound A2;

[0078] (2) Under nitrogen protection, weigh 760g of compound A2 into the reaction flask, control the temperature to 70±5°C, slowly add 60.3g of DMPA NMP solution dropwise to react with it, and stop the reaction when the detection-NCO value reaches the theoretical-NCO value to obtain compound B2;

[0079] (3) nitrogen protection, weigh 548.5g of diamine and add it to the reaction flask, at room temperature, slowly add 820.3g of compound B2 dropwise to react with it, detect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com