Ester-group-containing polyamine quaternary ammonium salt type asphalt emulsifier, emulsified asphalt, preparation methods of asphalt emulsifier and emulsified asphalt and application of asphalt emulsifier

A technology of ester-based polyamine quaternary ammonium salt and asphalt emulsifier, which is applied in the field of ester-based polyamine quaternary ammonium salt-type asphalt emulsifier, can solve the problems of cumbersome reaction steps, limited raw material sources, and high requirements for production and experimental equipment. Achieve the effects of improved stability, excellent performance indicators, good aggregate adhesion and storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] In one embodiment of the present invention, a kind of ester group-containing polyamine quaternary ammonium salt type asphalt emulsifier preparation method is provided, comprising the following steps:

[0036] (1) Tall oil fatty acid, alcohol solvent and epoxy chlorohydrin mixed reaction, obtain reaction intermediate I, the structural formula of described reaction intermediate I is

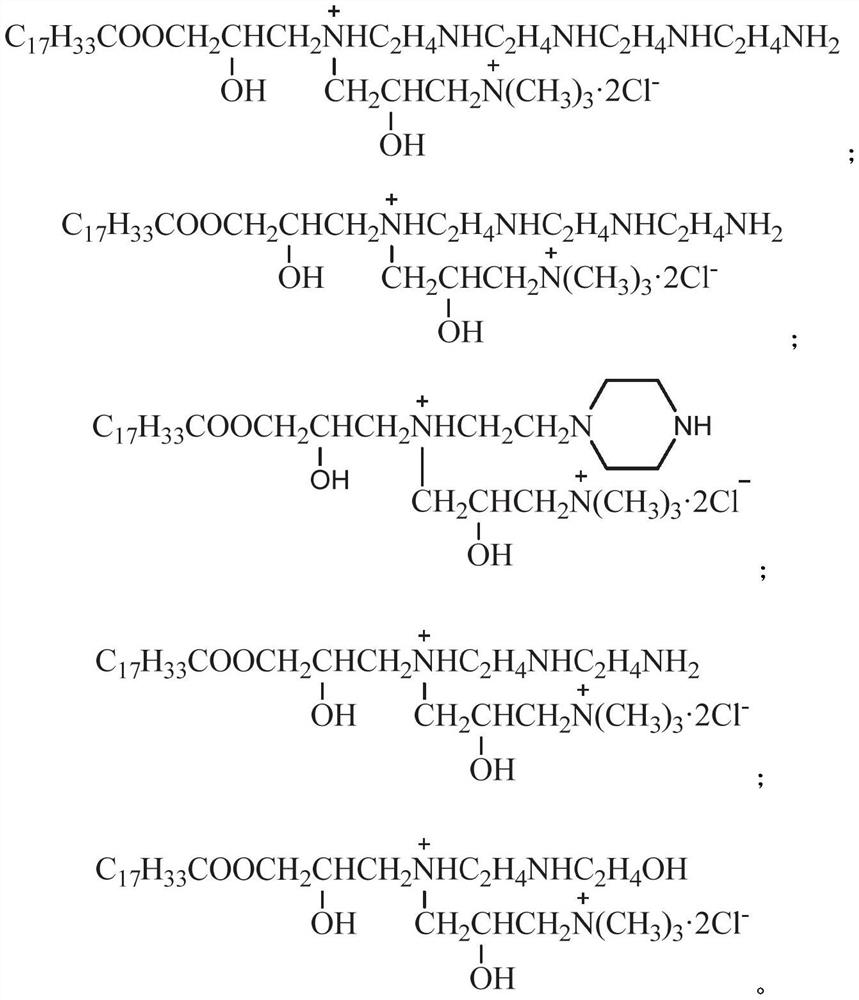

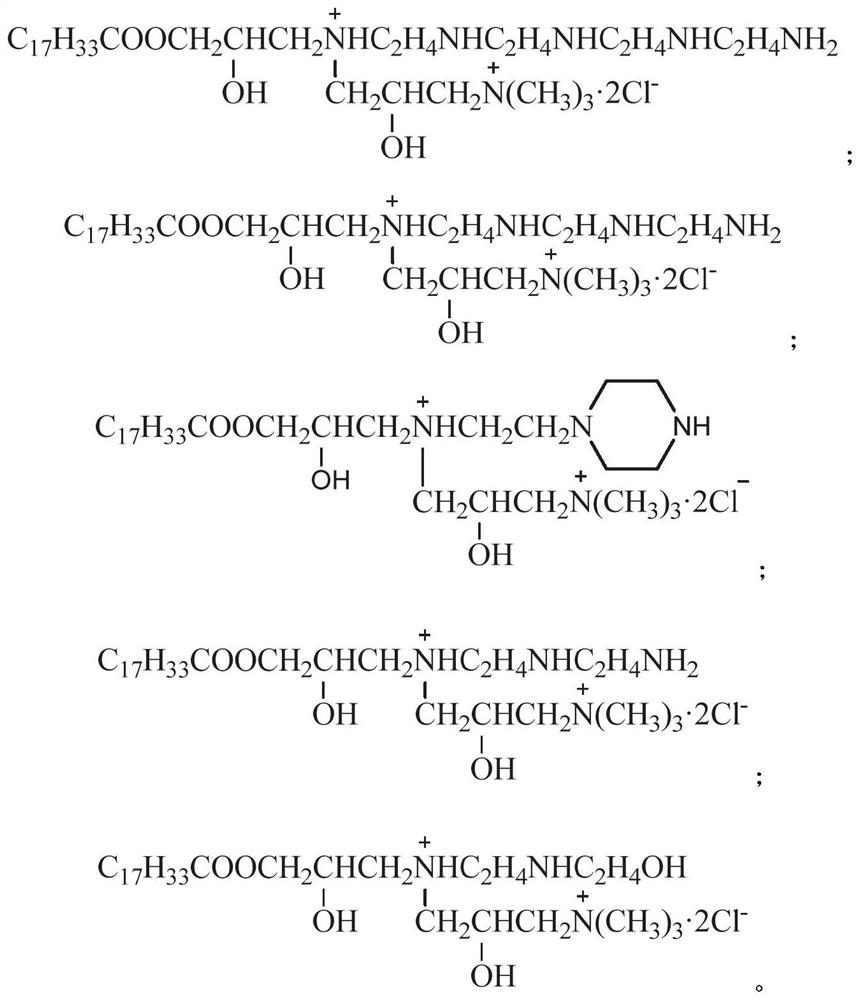

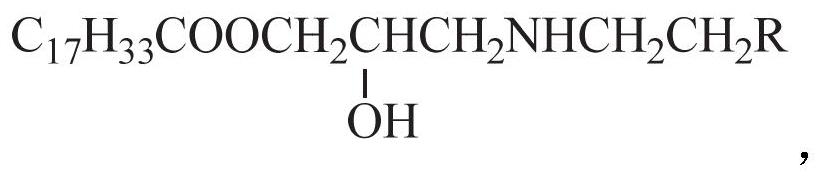

[0037] (2) in reaction intermediate I, add polyamine compound gradually again, mixed reaction, obtain reaction intermediate II, the structural general formula of described reaction intermediate II is

[0038] Among them, R is -NH(CH 2 CH 2 NH) m -H, -NHCH 2 CH 2 OH, m=1, 2, 3, the polyamine compound is tetraethylenepentamine, triethylenetetramine, N-aminoethylpiperazine, β-hydroxyethylethylenediamine or diethylenetriamine;

[0039] (3) Trimethylamine aqueous solution, hydrochloric acid and epichlorohydrin are mixed and reacted to obtain reaction intermediate III;

[0040](4) Grad...

Embodiment 1

[0062] (1) Preparation of ester-containing polyamine quaternary ammonium salt type asphalt emulsifier:

[0063] 1) Add 282.5g tall oil fatty acid and 100g isopropanol in the reactor, heat and stir to mix. Gradually add 95.2 g of epichlorohydrin at 55°C, and then stir and react at 55°C for 3 hours to obtain reaction intermediate I;

[0064] The response is as follows:

[0065]

[0066] The infrared spectrogram analysis result of synthesized reaction intermediate I is as follows: 3010cm -1 It is the superposition peak of the stretching vibration absorption peak of epoxy group C-H and double bond C=C-H, 2926cm -1 It is the asymmetric stretching vibration absorption peak of methylene, 2856cm -1 Closed peak for the symmetrical stretching vibration of methylene, 1711cm -1 It is the stretching vibration absorption peak of C=O double bond, 1648cm -1 It is the C=C double bond stretching vibration absorption peak, 1460cm -1 For the asymmetric bending vibration of methylene, 141...

Embodiment 2

[0082] (1) Preparation of ester-containing polyamine quaternary ammonium salt type asphalt emulsifier:

[0083] 1) Add 282.5g tall oil fatty acid and 100g isopropanol in the reactor, heat and stir to mix. Gradually add 95.2 g of epichlorohydrin at 50°C, and then stir and react at 50°C for 4 hours to obtain reaction intermediate I;

[0084] The response is as follows:

[0085]

[0086] 2) Gradually add 147.7 g of triethylenetetramine to the reaction intermediate I. After the addition, react at 65°C for 3 hours to obtain the reaction intermediate II;

[0087] The response is as follows:

[0088]

[0089] 3) In another reactor, add 193.1g trimethylamine aqueous solution (mass fraction 33%), gradually add 131.2g industrial hydrochloric acid (mass fraction 30%), then gradually add 97.1g epichlorohydrin, after adding, at 45 ℃ The reaction was stirred for 2h to obtain reaction intermediate III;

[0090] The response is as follows:

[0091]

[0092] 4) Gradually add reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com