Copper-clad plate and preparation method thereof

A copper-clad laminate and inorganic filler technology, applied in chemical instruments and methods, paper/cardboard layered products, synthetic resin layered products, etc., can solve the problem of limited material use temperature and application range, reduced electrical performance, and inability to adapt to high-end markets And other problems, to achieve the effect of good machining performance, good reliability, high tracking index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

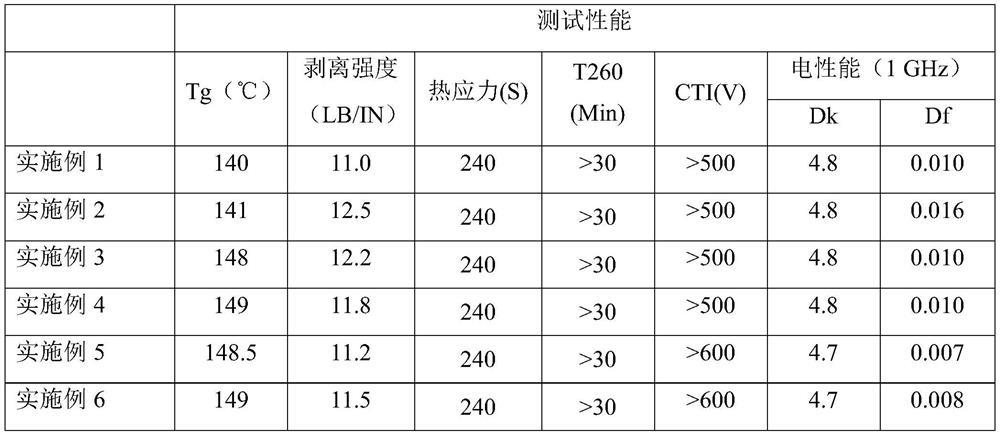

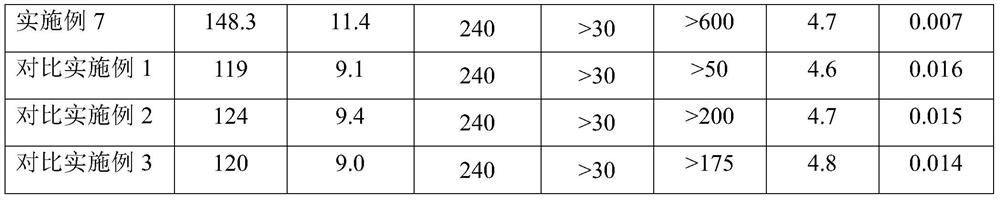

Examples

preparation example Construction

[0032] The present application also provides a method for preparing a copper clad laminate, which specifically includes the following steps:

[0033] Glue compounding: Stir 70-90 parts of solvent and 350-450 parts of brominated epoxy resin in a beaker according to parts by weight. After stirring evenly, continue to add 7-10 parts of dicyandiamide and 0.1-0.25 parts of curing accelerator , 35-60 parts of inorganic filler and 0.5-1 part of silane, stirred until completely dissolved to form a prepreg;

[0034] Impregnation: pour the compounded glue into the impregnation tank, impregnate the above-mentioned prepreg with glass cloth, and bake at 160-220°C for 3-10 minutes; put a layer of glass cloth or Laminate multiple layers together, and finally cover both sides of the laminated glass cloth with copper foil, and press 8 to 12 pieces of kraft paper at 0.4 to 3.7 MPa and 130 to 195°C for 120 to 160 minutes to obtain a laminated glass cloth. Copper foil laminate samples.

[0035]...

Embodiment 1

[0049]The raw material composition of the copper clad laminate includes: 70 parts of dimethylformamide and 350 parts of brominated epoxy resin are stirred in a beaker, and after stirring evenly, continue to add 7 parts of dicyandiamide, 0.1 part of 2-methyl Imidazole, 28 parts of aluminum hydroxide, 7 parts of zinc borate and 0.5 part of silane were stirred until they were completely dissolved to form a prepreg. In this embodiment, the particle size of the inorganic filler was selected to be 3um.

[0050] Pour the compounded glue solution into the impregnation tank, impregnate the above prepreg with glass cloth, and bake it at 160°C for 9 minutes; stack the baked glass cloths one by one, and finally put the laminated The laminated glass cloth is covered with copper foil on both sides, and pressed together with 9 pieces of kraft paper at 0.7MPa and 150°C for 150min to obtain a copper-clad laminate sample.

[0051] Test: Take out the laminate and test according to each test meth...

Embodiment 2

[0053] The raw material composition of the copper clad laminate includes: 80 parts of dimethylformamide and 400 parts of brominated epoxy resin are stirred in a beaker, and after stirring evenly, 8.6 parts of dicyandiamide and 0.17 parts of 2-methyl Imidazole, 35 parts of aluminum hydroxide, 5 parts of zinc borate and 0.7 part of silane were stirred until they were completely dissolved to form a prepreg. In this embodiment, the particle size of the inorganic filler was selected to be 14um.

[0054] Pour the compounded glue solution into the impregnation tank, impregnate the above prepreg with glass cloth, and bake it at 190°C for 8 minutes; stack the baked glass cloths one by one, and finally put the laminated The laminated glass cloth is covered with copper foil on both sides, and pressed together with 10 pieces of kraft paper at 3.5MPa and 140°C for 140min to obtain a copper-clad laminate sample.

[0055] Test: Take out the laminate and test according to each test method, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com