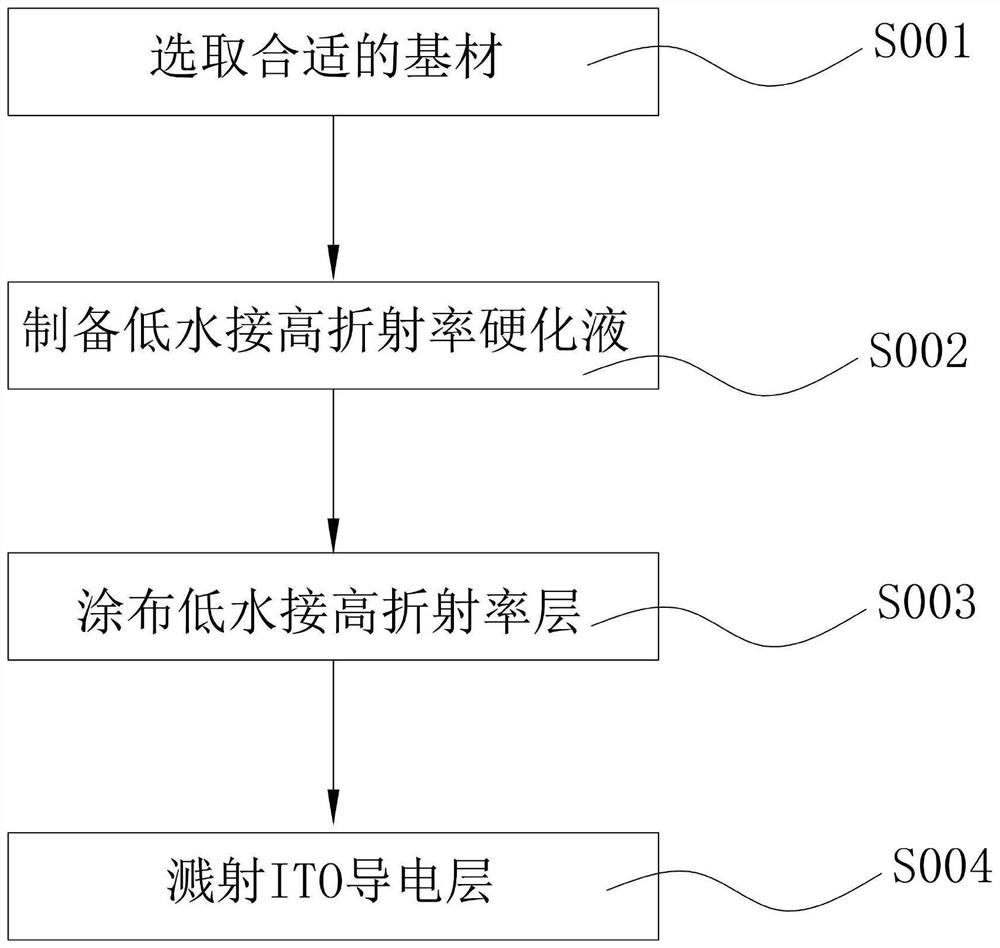

Low-water-connection high-refractive-index hardening liquid and method for preparing ITO conductive membrane by using same

A high-refractive-index, hardening liquid technology, applied in the direction of equipment, circuits, and electrical components used to manufacture conductive/semiconductive layers, can solve the problems of poor preparation effect and cumbersome preparation process of ITO conductive film, and achieve the effect of overcoming preparation. Poor, good preparation effect, overcoming the effect of cumbersome preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This embodiment provides a low-water contact high-refractive index hardening solution, which includes a high-wear-resistant high-hardness resin, a high-refractive index filler, a dispersant, a photoinitiator, an organic solvent, and a recoatable leveling agent. agent. This low water contact high refractive index hardening fluid has the characteristics of low water contact angle and high refractive index. By adding high refractive index fillers, the refractive index can be further improved. By adding recoatable leveling agent, the low water contact height can be achieved, and the improvement can be achieved. Adhesion with ITO, by sputtering the ITO conductive film on the hardened layer formed after the low-water contact high-refractive index hardening solution is cured, it can effectively remove the etching lines on the ITO conductive film, and effectively improve the adhesion between the base film and the ITO conductive film. Adhesion, good preparation effect.

[0024]...

Embodiment 2

[0037] The difference between the low-hydration high-refractive index hardening solution provided in this embodiment and the embodiment 1 is that the high-refractive index filler is 20 parts by weight of zirconium acrylic acid, and other components remain unchanged.

[0038] The difference between the method of preparing an ITO conductive film with a low-water high-refractive index hardening solution provided in this embodiment and that of Embodiment 1 is that in step S002, when configuring component B, 20 parts by weight of zirconium acrylic acid, other The ingredients are unchanged.

Embodiment 3

[0040] The difference between the low-hydration and high-refractive-index hardening solution provided in this example and Example 1 is that the high-wear-resistant and high-hardness resin is 10 parts by weight of polyurethane acrylate compound, and the high-refractive index filler is 40 parts by weight of zirconium Acrylic acid, dispersant is the dispersant 2140 of 4 weight parts, photoinitiator is the photoinitiator 184 of 2 weight parts, and organic solvent is the mixture of the ethyl acetate of 30 weight parts and the methyl isobutyl ketone of 30 weight parts, can The leveling agent for recoating is 0.2 parts by weight of leveling agent A227.

[0041] This embodiment also provides a method for preparing an ITO conductive film with a low-water contact high-refractive index hardening solution. 30 parts by weight, after stirring evenly, add 2 parts by weight of photoinitiator 184, stir evenly to obtain component A; take 30 parts by weight of methyl isobutyl ketone, add 4 parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap