Low-temperature antirust agent suitable for fluoride-free refrigeration industry, preparation method and application thereof

A technology of anti-rust agent and anti-rust additive, which is applied in the direction of additives, petroleum industry, lubricating composition, etc., can solve the problems of scrapping, high energy consumption, capillary blockage of refrigeration system, etc., and achieve reduction of residual amount, excellent anti-rust performance, Solve the effect of capillary clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

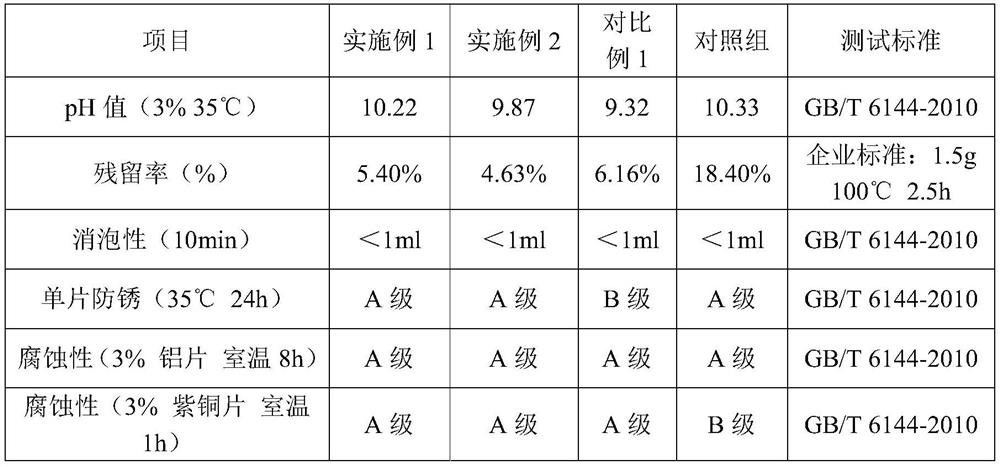

Examples

preparation example Construction

[0036] The preparation of antirust additive in the embodiment is as follows:

[0037] 12 parts of diethanolamine and 12 parts of boric acid were mixed and stirred at 100°C for 3 hours, and the stirring speed was 100 rpm to obtain reactant B for later use; 25 parts of pure water and 20 parts of ternary polycarboxylic acid were weighed in proportion , 20 parts of diethanolamine, mixed and stirred for 1 hour at normal temperature, then added reactant B, mixed and stirred for 1 hour, finally added 11 parts of propylene glycol, mixed and stirred for 1 hour, and the stirring speed was 100 rpm to obtain the antirust additive . The parts are in mass fraction.

Embodiment 1-2

[0039] The preparation method of low temperature antirust agent in embodiment 1-2 is as follows:

[0040] Mix water, isopropanolamine, sebacic acid, isononanoic acid, tolyltriazole, diethylene glycol, propylene glycol methyl ether and anti-rust additives in sequence, and stir for 0.5 hours after each raw material is added, all Stir for 2 hours after adding the raw materials to obtain the low-temperature antirust agent suitable for the fluorine-free refrigeration industry. The amount of raw materials added is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com