Aviation fuel free water detection test paper as well as preparation method and detection device thereof

A technology of aviation fuel and test paper, which is applied in the field of aerospace, can solve the problems of reducing the viscosity of aviation fuel, short storage period, and risk in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

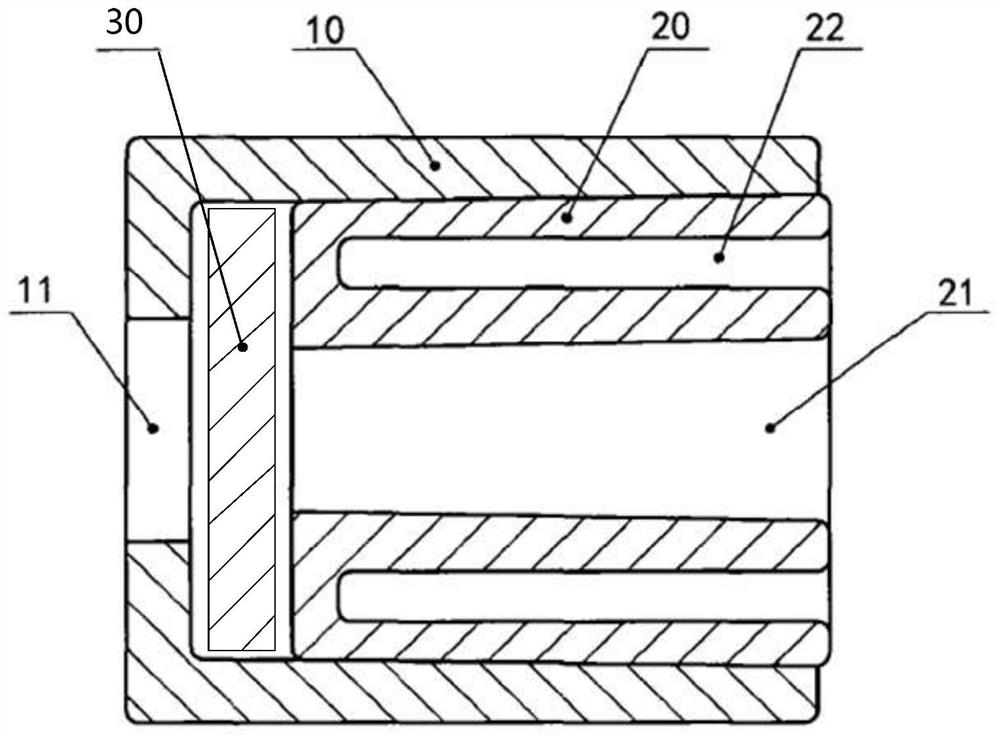

Method used

Image

Examples

preparation example Construction

[0060] Correspondingly, another embodiment of the present invention also provides a kind of preparation method of above-mentioned aviation fuel free water test paper, and it comprises the following steps:

[0061] S1), filter paper soaked K 3 [Fe(CN) 6 ] solution, and then dried to obtain intermediate detection test paper;

[0062] S2), in the middle detection test paper surface coating FeSO 4 Powder mix with chelating agent.

[0063] In the above preparation process:

[0064] Step S1 is the step of loading potassium ferricyanide on the filter paper. This step adopts a soaking-drying method, which can improve the uniformity of distribution of potassium ferricyanide on the surface of the filter paper, and form a light yellow test paper with uniform color distribution, and then Improve detection accuracy and sensitivity. In this step, K 3 [Fe(CN) 6 ] Solution concentration is preferably 3~10g / L, too low potassium ferricyanide solution will cause the loaded potassium ferri...

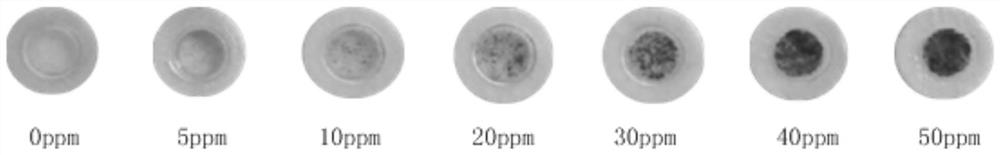

Embodiment 1-3 and comparative example 1-2

[0086] The test paper preparation process is as follows:

[0087] 1. Use rapid quantitative filter paper with a pore size of 100 μm and soak it in different concentrations of K 3 [Fe(CN) 6 ] solution, 1LK 3 [Fe(CN) 6 ] The solution soaks 200 pieces of filter paper, and the area of a single piece of filter paper is 225cm 2 . K used in Examples and Comparative Examples 3 [Fe(CN) 6 ] Solution concentration is listed in Table 1;

[0088] 2. Drying: The drying temperature is 60°C, the drying time is 30 minutes, and the intermediate test paper is obtained after drying;

[0089] 3. FeSO 4 The powder and citric acid were mixed according to the weight ratio of 100:0.5, and water-cooled ball milled to a particle size of 20 μm to obtain FeSO 4 powder mixture with chelating agent;

[0090] 4. Electrostatic powder spraying is used for coating, and FeSO is coated on the surface of the test paper in the middle 4 Powder mixture with chelating agent, the coating weight is 1.65mg / c...

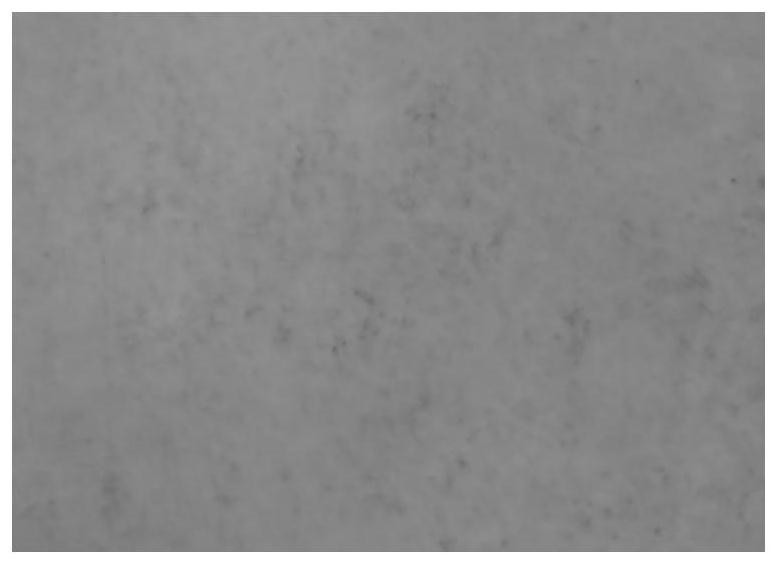

Embodiment 1、4-5, and comparative example 3

[0099] The test paper preparation process is as follows:

[0100] 1. Use different filter papers and soak them in K with a concentration of 5g / L 3 [Fe(CN) 6 ] solution, 1LK 3 [Fe(CN) 6 ] The solution soaks 200 pieces of filter paper, and the area of a single piece of filter paper is 225cm 2 . The filter paper type used in the embodiment and the comparative example is listed in table 2;

[0101] 2. Drying: The drying temperature is 60°C, the drying time is 30 minutes, and the intermediate test paper is obtained after drying;

[0102] 3. FeSO 4 The powder and citric acid were mixed according to the weight ratio of 100:0.5, and water-cooled ball milled to a particle size of 20 μm to obtain FeSO 4 powder mixture with chelating agent;

[0103] 4. Electrostatic powder spraying is used for coating, and FeSO is coated on the surface of the test paper in the middle 4 Powder mixture with chelating agent, the coating weight is 1.65mg / cm 2 .

[0104]The aviation fuel with fre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com