Preparation method and application of surface-mounted miniature filter capacitor

A filter capacitor and chip type technology, which is used in the preparation of chip type micro filter capacitors. With the help of micro-nano processing technology to customize the field of chip type micro filter capacitors, it can solve the problem that the way of fixed connection is not reliable and stable, and it is inconvenient to lead. The problems of bonding with the circuit board, such as conduction, micro-short circuit, and low ion transfer efficiency, achieve the effects of excellent conductivity, small ripple, and improved efficiency and utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

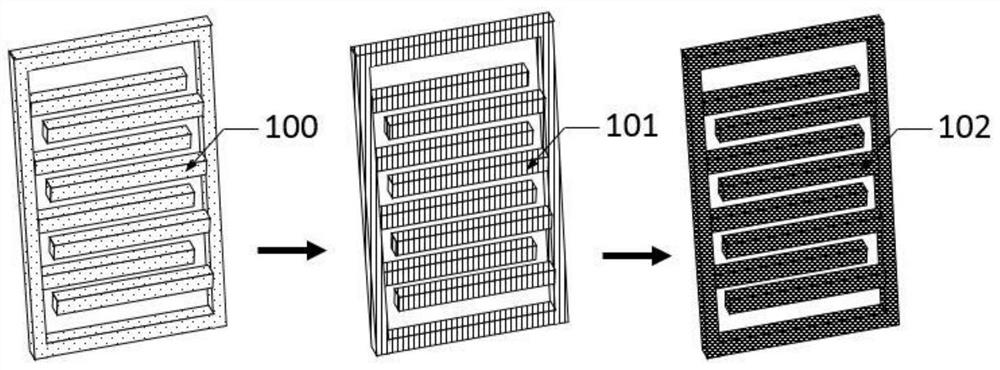

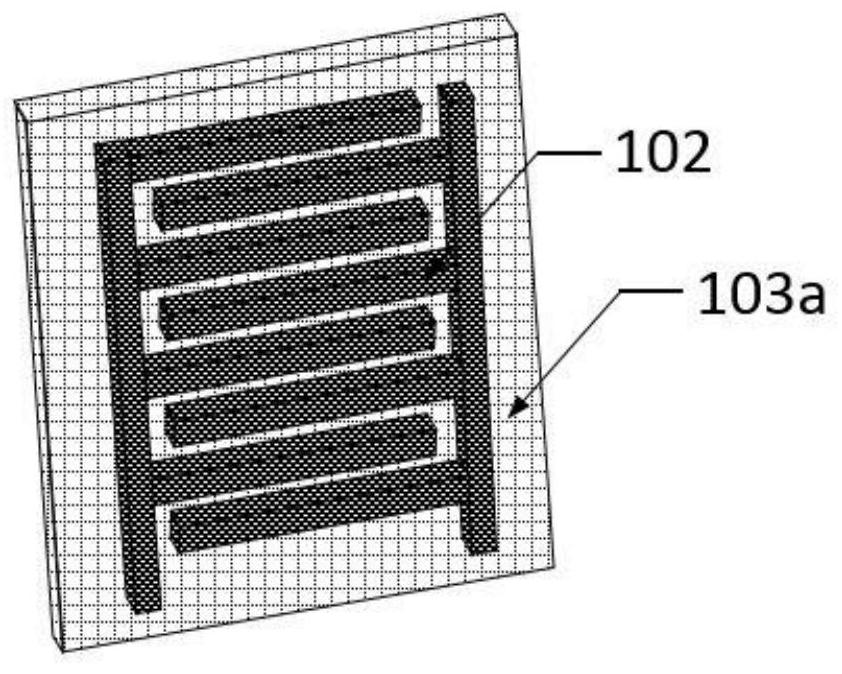

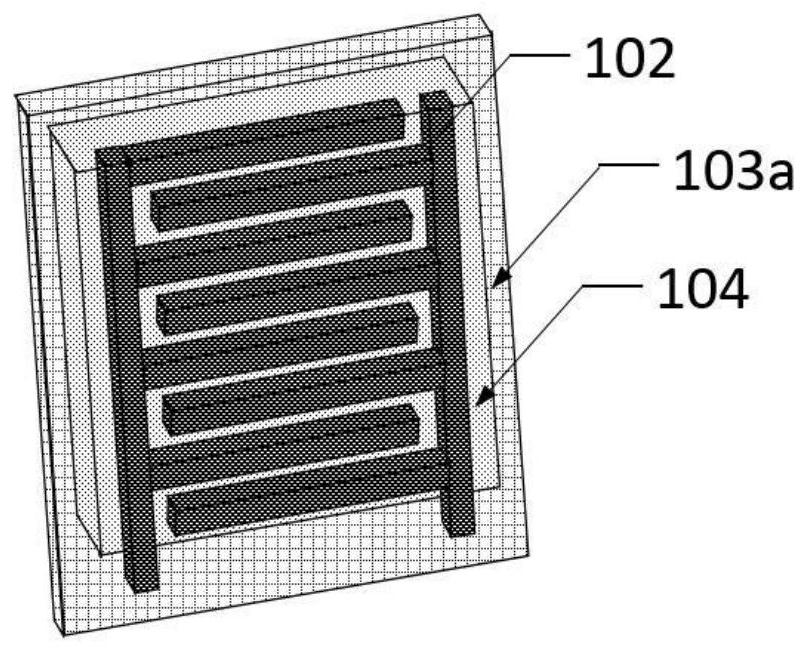

[0051] The 3D silicon-based capacitor includes a 3D silicon-based frame 100 , a current collector 101 , an active material 102 , an encapsulation case (including a supporting encapsulation case lower part 103 a and an encapsulation case upper part 103 b ), electrolyte 104 , conductive pins 105 and a circuit board 106 . Its preparation method may comprise the following steps:

[0052] 1. Fabrication of the 3D silicon-based frame 100 . Silicon wafers are used for semiconductor patterning processing to form a pair of comb-shaped electrodes, which serve as the overall 3D frame of the capacitor, such as figure 1 As shown, wherein, the length, width and height of the comb teeth can be flexibly designed and selectively designed on demand. The present invention aims to design miniaturized capacitors. Can;

[0053] Two, the conductive carbon material is used as the making of current collector 101, such as figure 1 shown. For this high aspect ratio 3D frame, the current collector 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com