Sea urchin-shaped cobalt-based photocatalyst and preparation method thereof

A photocatalyst, sea urchin-like technology, applied in the field of photocatalysis, can solve the problems of low catalytic efficiency, small specific surface area, complicated preparation, etc., and achieve the effects of high photocatalytic efficiency, large specific surface area, and low preparation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A kind of sea urchin-like cobalt-based photocatalyst provided by the invention and preparation method thereof, specifically comprise the following steps:

[0031] (1) Put 1 to 2 mol of p-aminobenzoic acid into 10 to 20 mL of a mixed solution containing equal volumes of DMF and ethanol, and stir for 10 to 30 minutes to obtain the organic ligand L;

[0032] (2) Add 1.5mol Co(NO 3 ) 2 ·6H 2 O, stirring for 10 to 30 minutes to form a mixed solution;

[0033] (3) Transfer the mixed solution to a stainless steel autoclave lined with Teflon, put it into a drying oven at 150-230° C. and heat it for 10-20 hours, and after cooling to 20-30° C., filter to obtain the primary product of the catalyst;

[0034] (4) Wash the catalyst primary product with 5-10mL DMF and 5-10mL ethanol respectively until its weight no longer changes, then dry the catalyst primary product in a vacuum oven at 70-90°C for 10-15 hours to obtain sea urchin-shaped The final cobalt-based photocatalyst.

Embodiment 1

[0036] A sea urchin-shaped cobalt-based photocatalyst and a preparation method thereof, specifically comprising the following steps:

[0037] (1) Put 1mol p-aminobenzoic acid into 10mL mixed solution containing equal volume of DMF and ethanol, stir for 10 minutes to obtain organic ligand L;

[0038] (2) Add 1.5mol Co(NO 3 ) 2 ·6H 2 O, stirred for 10 minutes to form a mixed solution;

[0039] (3) Transfer the mixed solution to a stainless steel autoclave with Teflon lining, put it into a drying oven at 150° C. and heat it for 10 hours, and after cooling to 25° C., filter to obtain the catalyst primary product;

[0040] (4) Wash the primary catalyst product 3 times with 5mL DMF and 5mL ethanol, until its weight no longer changes, then dry the primary catalyst product in a vacuum oven at 70°C for 10 hours to obtain the final product of sea urchin-like cobalt-based photocatalyst .

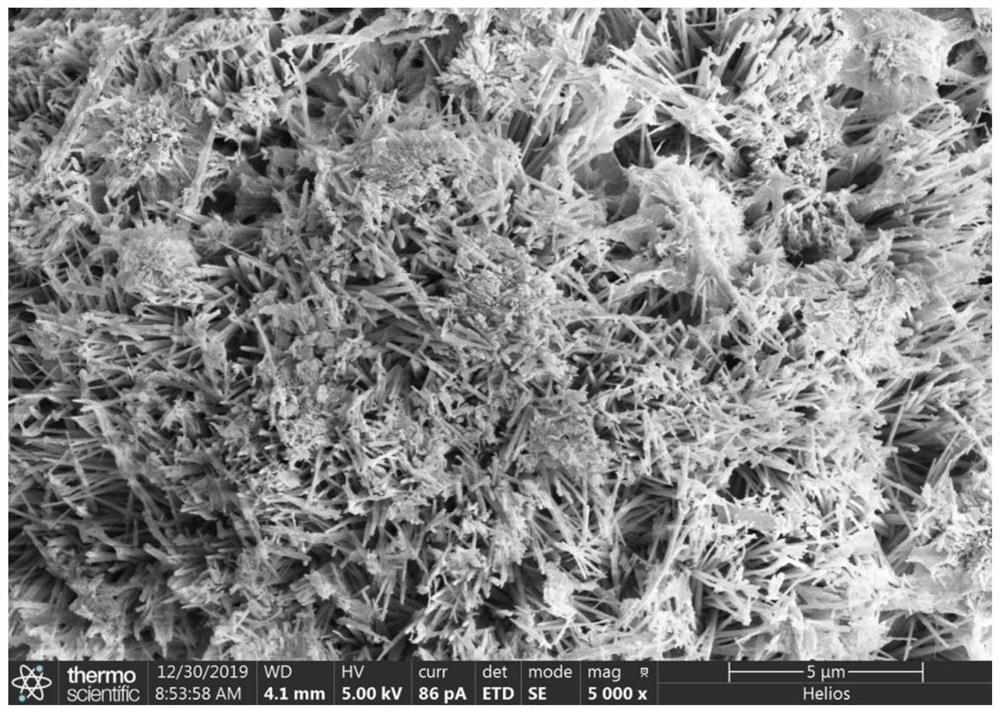

[0041] Figure 4 It is a 2000 times enlarged SEM image of a kind of sea urchin-like cobalt-ba...

Embodiment 2

[0043] A sea urchin-shaped cobalt-based photocatalyst and a preparation method thereof, specifically comprising the following steps:

[0044] (1) Put 1.5mol p-aminobenzoic acid into 15mL mixed solution containing equal volume of DMF and ethanol, stir for 20 minutes to obtain organic ligand L;

[0045] (2) Add 1.5mol Co(NO 3 ) 2 ·6H 2 O, stirred for 20 minutes to form a mixed solution;

[0046] (3) Transfer the mixed solution to a stainless steel autoclave with Teflon lining, put it into a drying oven at 200° C. and heat it for 15 hours, and after cooling to 25° C., filter to obtain the catalyst primary product;

[0047] (4) Wash the primary catalyst product 3 times with 7mL DMF and 7mL ethanol, until its weight no longer changes, then dry the primary catalyst product in a vacuum oven at 80°C for 12 hours to obtain the final product of sea urchin-like cobalt-based photocatalyst .

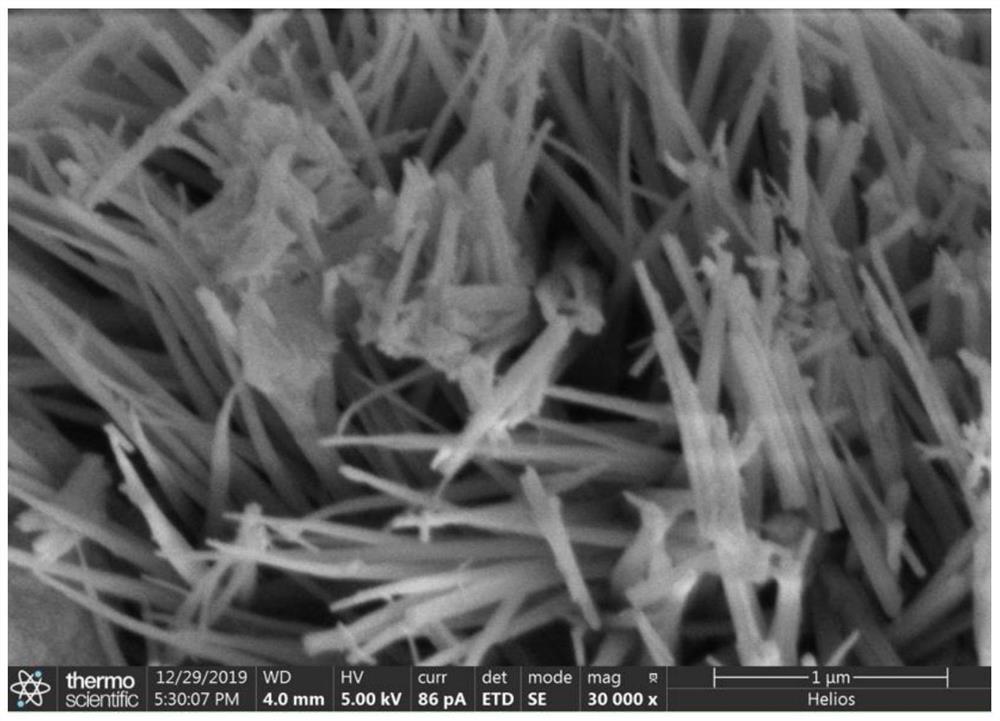

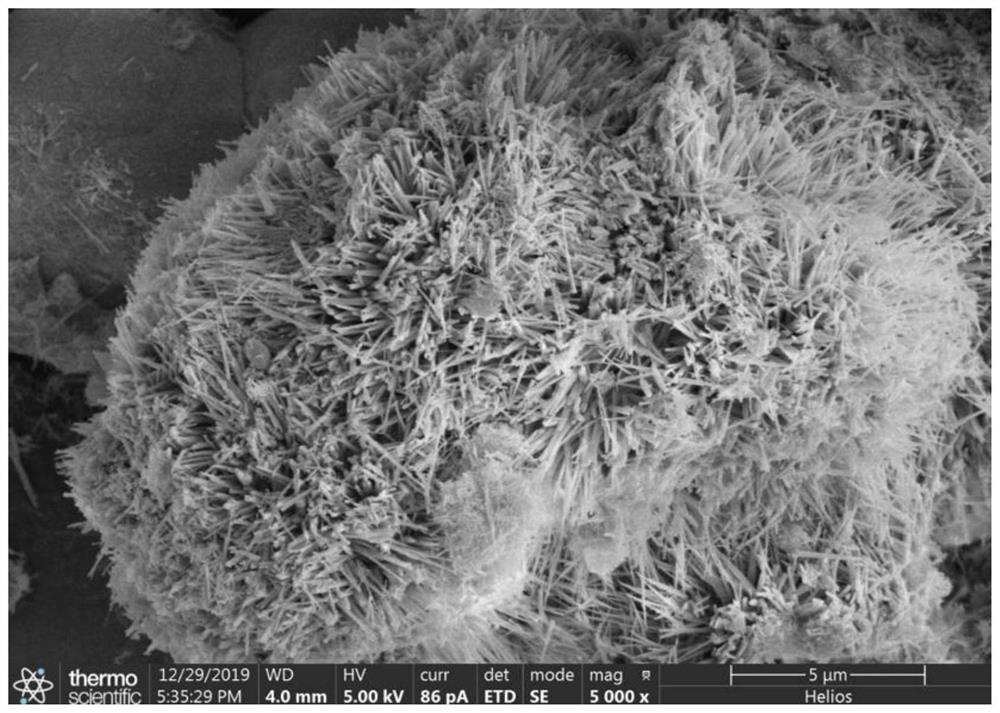

[0048] figure 2 It is a 5000 times enlarged SEM figure of a kind of sea urchin-shaped coba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com