Vinasse residue-liquid rapid separation device for white spirit production

A separation device, the technology of distiller's grains residue, applied in the direction of presses, manufacturing tools, etc., can solve the problems of increasing the labor intensity of workers, affecting the effect of separation, affecting the effect of extrusion, etc., and achieves good automation effect, convenient replacement, extrusion. good pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

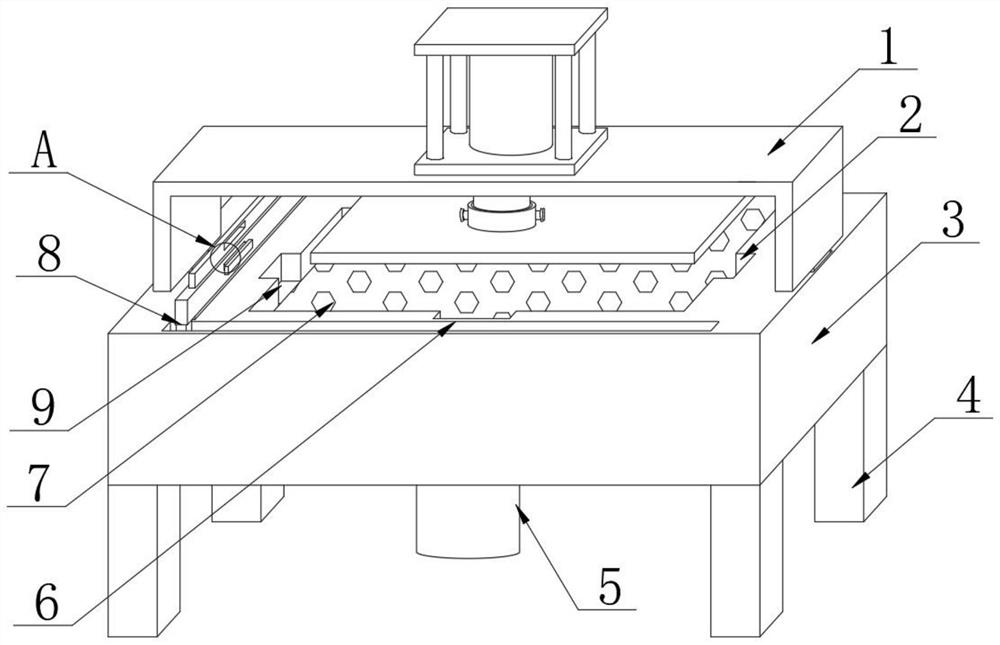

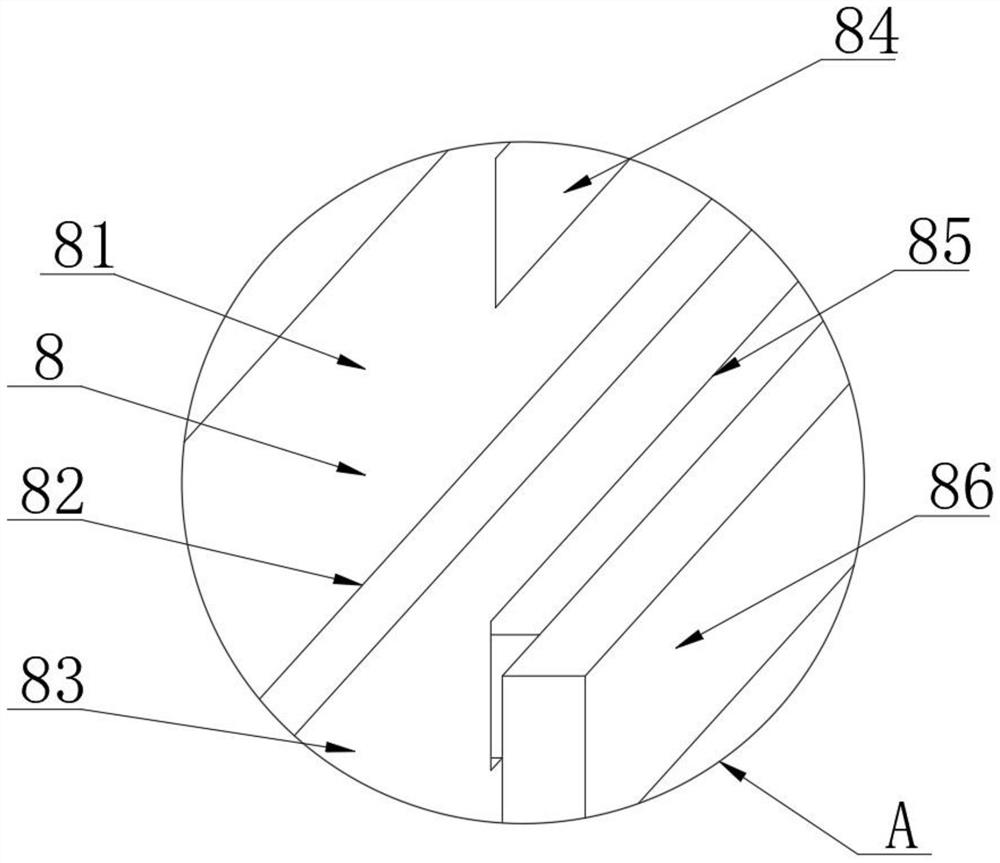

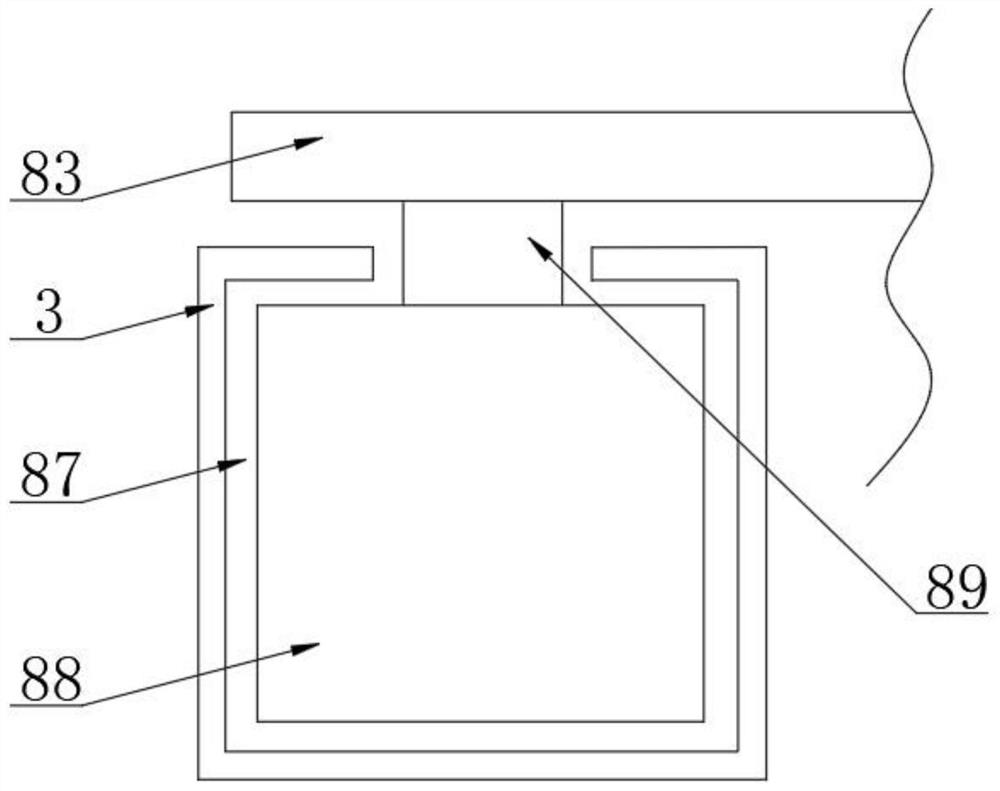

[0026] see Figure 1-6 , in an embodiment of the present invention, a distiller's grain liquid rapid separation device for liquor production includes a separation pool 3, a base 4 is integrally installed at the bottom of the separation pool 3, and a first installation is provided on the upper surface of the separation pool 3. Slot 2, the inside of the first installation groove 2 is slidably installed with a first slide plate 9, one end of the first slide plate 9 is fixedly connected to one side of the separation plate 7, the upper surface of the separation pool 3 is clamped with a separation assembly 1, and the separation assembly 1 Including cylinder 11, fixed plate 12, fastening bolt 13, card slot 14, bayonet pin 15, connecting sleeve 16 and pressure plate 17, the upper surface of fixed plate 12 is fixed with cylinder 11, and the bottom of fixed plate 12 is integrally installed with Bayonet 15, the end of bayonet 15 is embedded in the inside of bayonet groove 14, bayonet pin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com